Brushless joint-control motor soft starter

A soft starter and motor control technology, which is used in motor generators/starters, starters of a single multi-phase induction motor, etc., can solve the problem of small diameter of the catheter, inconvenient debugging of the contact speed of the dynamic and static plates, and inability to timely Exhaust gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

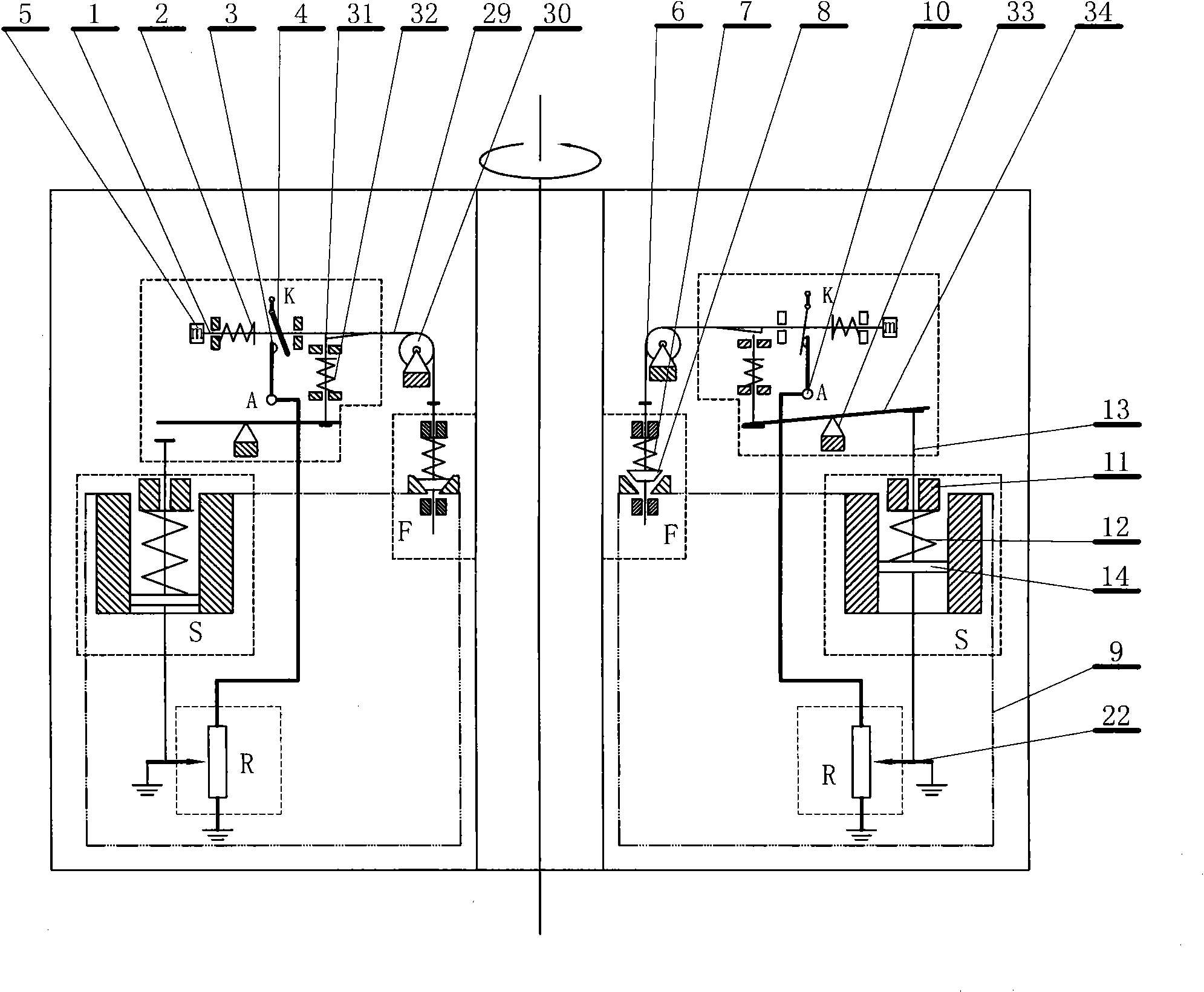

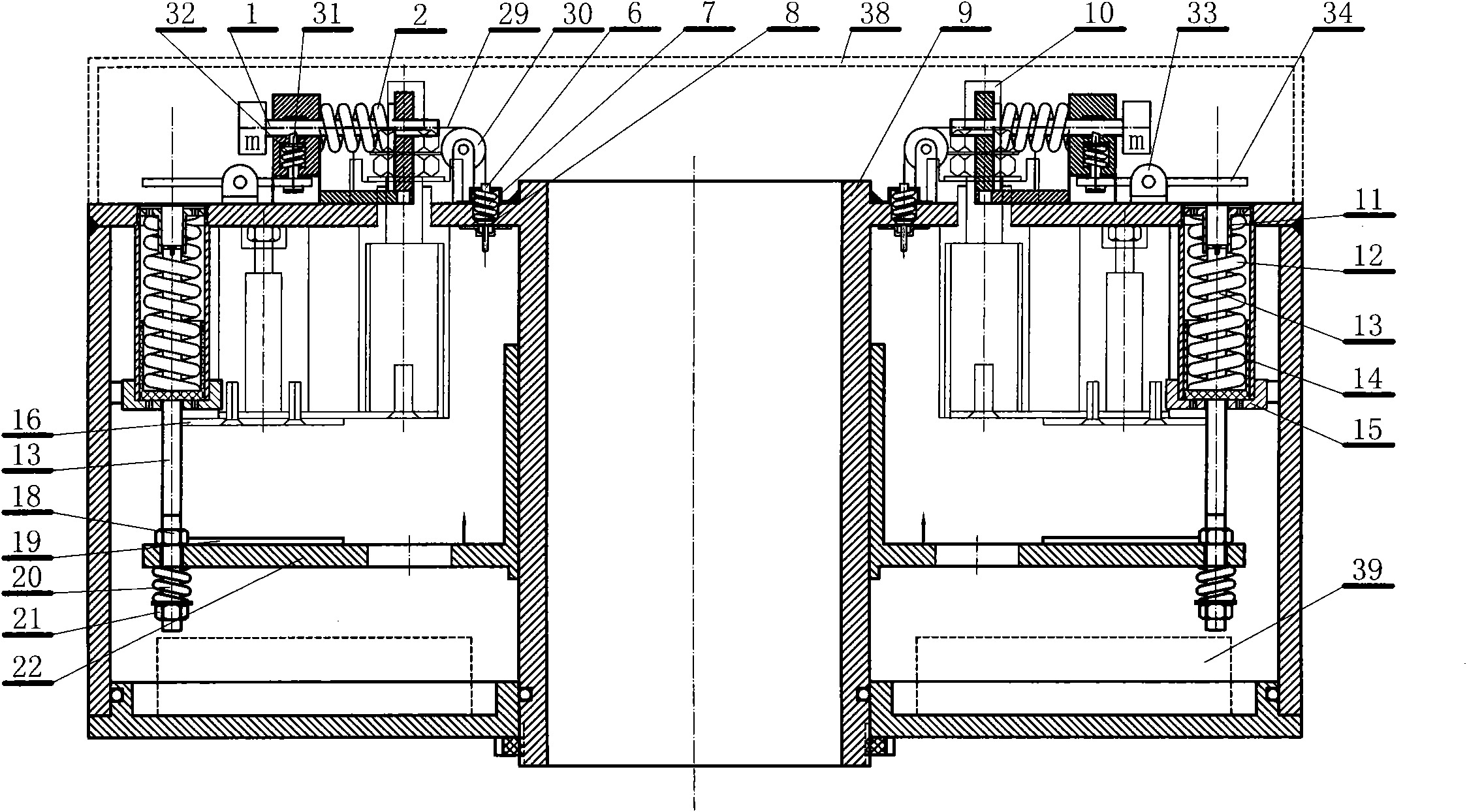

[0028] Embodiment one: if figure 1 , image 3 As shown, the brushless combined control motor soft starter adds pistons, levers and pulleys on the basis of the existing starter, and also has variable water resistance, double-controlled short-circuit switches outside the water resistance box, and combined safety exhaust. Air valve three devices. One end of the piston rod 13 in the piston is connected with the water resistance pole plate 22, and is used to adjust the resistance when the motor is started according to the speed when the motor is started, so as to reduce the fluctuation of the motor starting current. The variable water resistance controlled by the piston, when the load of the motor is heavy, the steam pressure generated by the water resistance will accelerate the reduction of the resistance value of the water resistance, avoiding a low valley current, thereby increasing the starting torque of the motor, The occurrence of the failure phenomenon of the motor to star...

Embodiment 2

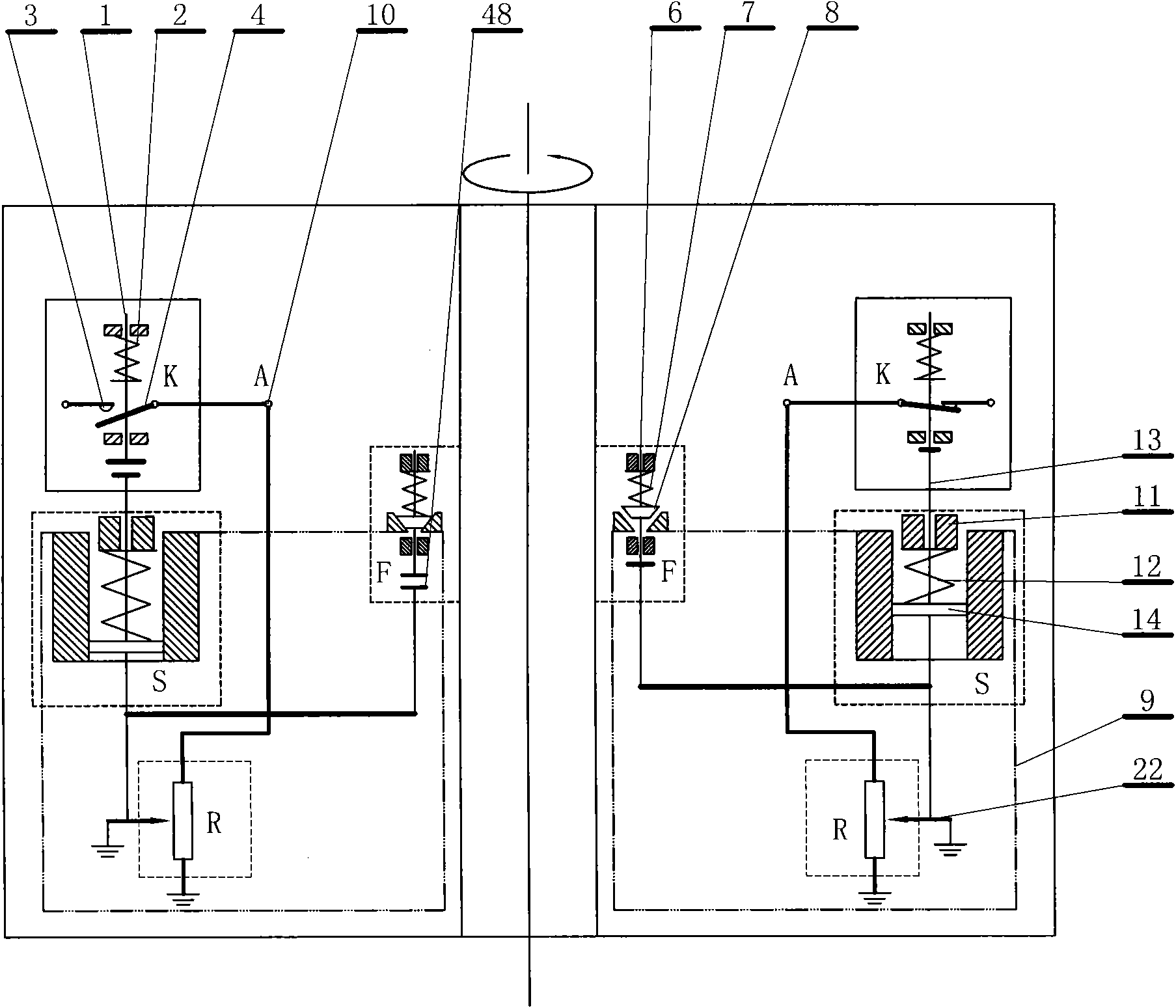

[0036] Embodiment 2: as figure 2 , Figure 4 As shown, the brushless combined control motor soft starter is an omitted implementation of Embodiment 1, and its main structure is basically the same as that of Embodiment 1. It also has three devices: variable water resistance, short circuit switch and combined safety exhaust valve, but the short circuit switch is single-controlled. One end of the piston rod 13 in the piston is connected with the water resistance plate disc 22, and is used for adjusting the resistance when the motor starts according to the rotating speed when the motor starts. Because the static and dynamic plates use graphite plates, the occurrence of electric corrosion and fusion welding is reduced. The other end of the piston rod 13 is connected with the moving contact 4 of the short circuit switch; and the static contact 3 is fixed on the moving contact 4 through the compression spring 2 and the guide rod 1 . When the motor is started, the piston rod 13 di...

Embodiment 3

[0037] Embodiment 3: as Figure 5 As shown, the brushless combined control motor soft starter is another omitted implementation of the first embodiment. It adds a pulley mechanism to the existing starter. The water resistance is fixed, and the fixed water resistance adopts the pole plate 24 to be fixedly installed in the water resistance container. When the water resistance adopts a fixed type, because the size of the water resistance does not need to be controlled by the piston rod 13, the piston only needs to control the short circuit switch, the required stroke is short, and it is not necessary to carry out joint control with the water resistance, and the piston and the lever can be omitted. At this time, the inclination angle α of the groove of the guide rod 1 of the short circuit switch is smaller than the friction angle β. Drive the moving contact (4) to move to the static contact (3). By adjusting the pressure of the spring 32 of the short-circuit switch lock guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com