Making method for printed-circuit boards and palladium removing device for printed-circuit boards

A technology for printed circuit boards and manufacturing methods, which is applied in the field of palladium removal for printed circuit boards and the production of printed circuit boards. It can solve the problems of sinking nickel and gold, affecting the reliability of HDI boards, etc., and achieve the effect of improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

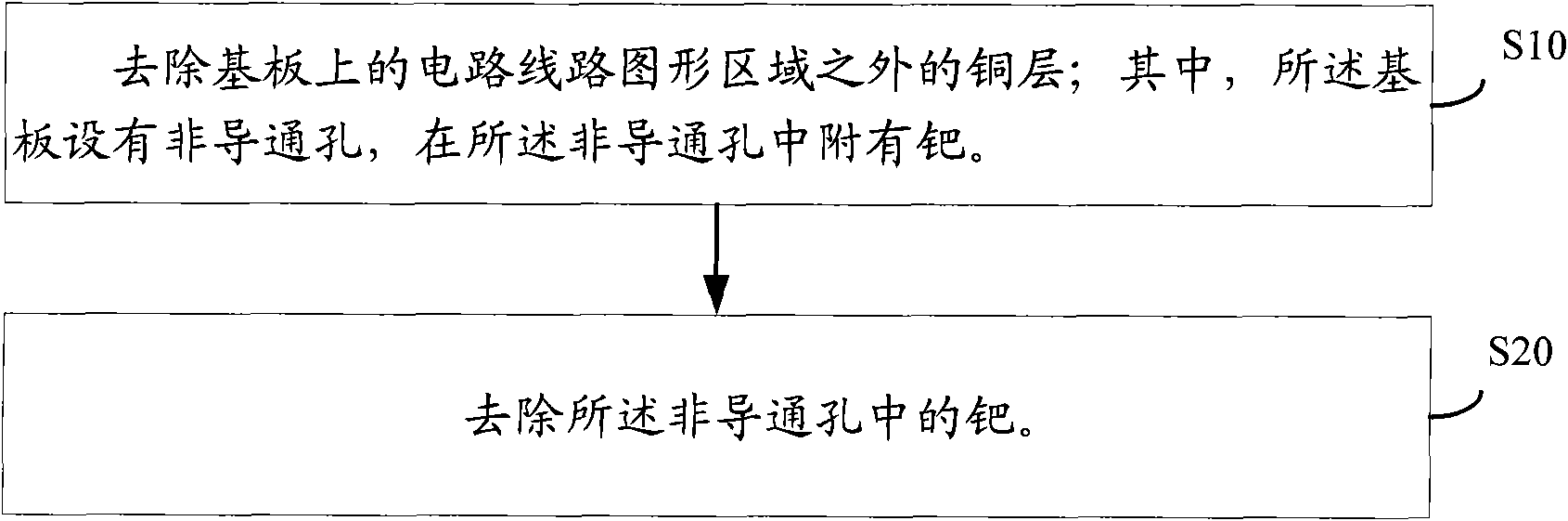

[0017] This embodiment provides a method for manufacturing a printed circuit board. Such as figure 1 As shown, a method for manufacturing a printed circuit board includes:

[0018] S10: removing the copper layer outside the circuit pattern area on the substrate; wherein, the substrate is provided with a non-conducting hole, and palladium is attached to the non-conducting hole;

[0019] S20: removing palladium in the non-conducting holes.

[0020] Wherein, removing the copper layer outside the circuit pattern area on the substrate specifically includes: removing the copper layer outside the circuit pattern area through an etching process. In this embodiment, a horizontal alkaline etching machine is used to perform etching using an ammonium chloride etching solution. Among them, the upper pressure of the etching section of the horizontal alkaline etching machine is 2.0-3.0Kgf, the lower pressure of the etching section is 1.1-1.5Kgf, the chloride ion concentration is controlle...

Embodiment 2

[0039] This embodiment provides a method for removing palladium for manufacturing printed circuit boards, the method can remove palladium in non-conducting holes of the circuit board, and can improve the performance of the circuit board.

[0040] In order to solve the above technical problems, the present invention adopts the following technical solutions:

[0041] A method for removing palladium used for manufacturing printed circuit boards. The palladium removing agent used for palladium removal is a mixed solution of hydrochloric acid solution and thiourea solution. Wherein, the hydrochloric acid solution in the mixed solution is 16-20 g / L of hydrochloric acid with a mass percent content of 37%, and the concentration of the thiourea solution is 60-80 g / L.

[0042] Further, in the mixed solution, the mass ratio of the hydrochloric acid solution and the thiourea solution is 1:3.8.

[0043] Furthermore, the working temperature of the mixed solution is 20-40°C.

[0044] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com