Automatic sanding and polishing device for industrial robot

An industrial robot and polishing device technology, applied in the direction of grinding/polishing equipment, manufacturing tools, abrasive belt grinders, etc., can solve the problems of dust generation, low efficiency, poor product consistency, etc., to ensure positioning accuracy, improve sanding and Consistent polishing efficiency and removal amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

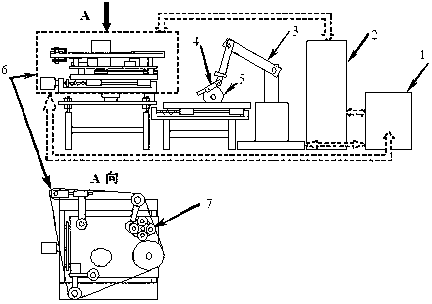

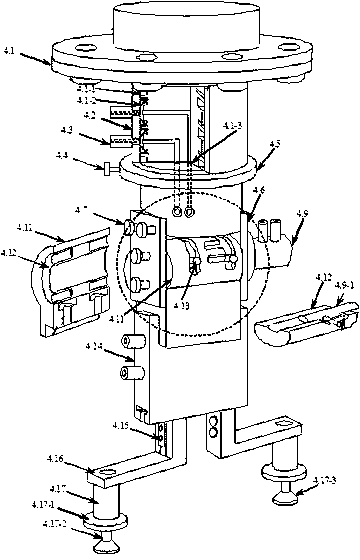

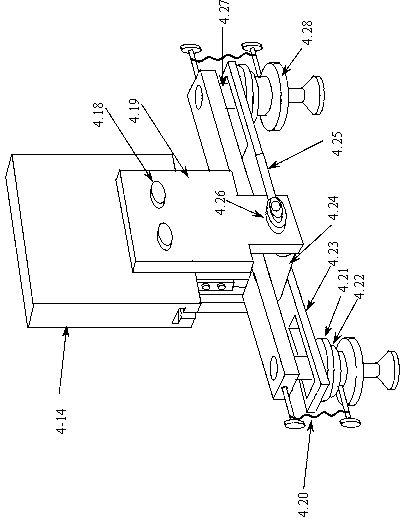

[0028] Such as figure 1 As shown, the automatic sanding and polishing device is composed of an industrial robot 3, an automatic displacement fixture 4, a floating polishing machine tool 6, software automatic force control programming, a deburring grinding wheel 5, and a part positioning mechanism. The automatic displacement fixture 4 is installed in an industrial The end of the robot 3 is used to automatically clamp the processed parts, and through the automatic displacement of the clamps, sand and polish any area of the parts on the floating polishing machine 6; The industrial robot 3 with the position fixture 4 cooperates to sand and polish the parts clamped on the fixture by using the abrasive belt on the polishing machine. tightening mechanism, abrasive belt wear automatic compensation mechanism and auxiliary wheel automatic conversion mechanism; softw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com