Loading and unloading handling mechanical arm for solar cell module

A technology of solar cells and manipulators, applied in furnace components, charge manipulation, conveyor objects, etc., can solve the problems of large volume and weight of solar cell modules, difficulty in handling solar cell modules, and small end effectors, etc., to improve labor productivity. , to avoid the effect of high fragmentation rate and balanced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described in detail below in combination with the technical scheme and accompanying drawings.

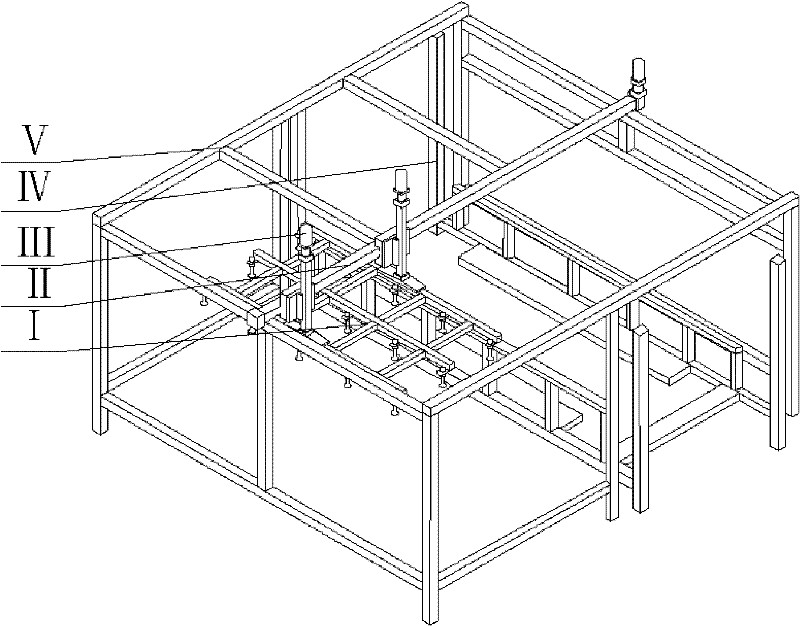

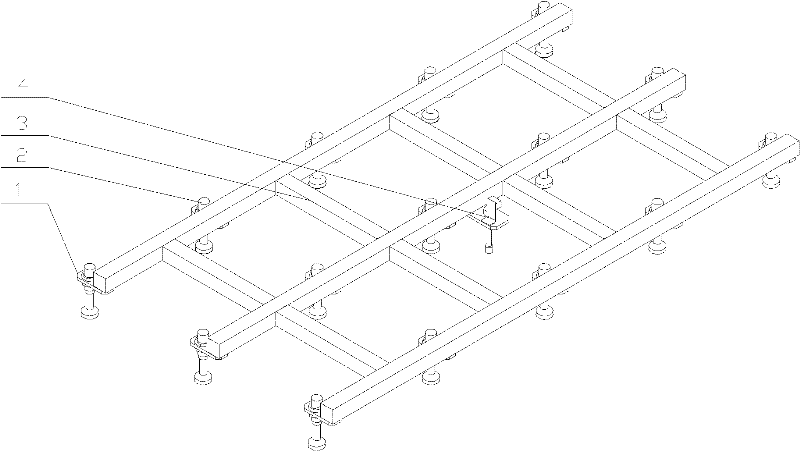

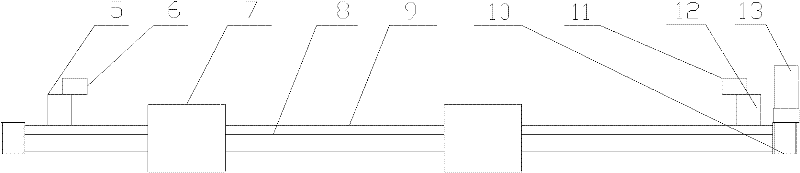

[0032] The manipulator for loading and unloading solar cell modules of the present invention is composed of a manipulator mechanism I, a horizontal movement unit II, two sets of vertical movement units III, a tray lifting mechanism IV and a body V. As the main body of clamping force, the relative position between the suction cups can be adjusted. The horizontal motion unit is driven by the X-direction servo motor through the synchronous toothed belt deceleration mechanism to drive the manipulator to perform horizontal reciprocating motion. The vertical motion unit is driven by the Z-direction servo motor through the ball screw nut pair to drive the manipulator mechanism to move up and down. Finally, the loading and unloading operation of the solar cell module is completed by the tray lifting mechanism and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com