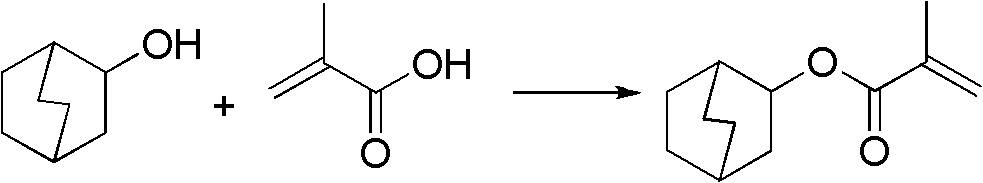

Bornylene ester and preparation method thereof

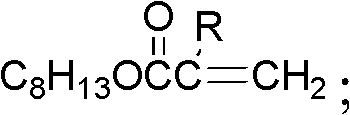

A technology of bornene ester and onene ester, which is applied in the field of bornene ester and its preparation, can solve the problems of norbornene tricyclic structure instability, extensive limitation, short life, etc., achieve high yield, simple reaction, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Select acrylic acid for esterification

[0025] Mix 100g of borneol and 300g of acrylic acid in a 1L four-necked bottle, add 10ml of 98% concentrated sulfuric acid, and 8g of phenothiazine crystals, dissolve in 450ml of toluene solution, stir, and reflux at a temperature between 110-120°C , send samples after 2h of reaction, use HPLC to detect, stop the reaction when the content of borneol is less than 2g;

[0026] Cool down to 100°C, add 5g of activated carbon and reflux for 1h, then cool down to 50°C while hot suction filtration, the filter cake is washed three times with 150ml of water, and then washed with 150ml of 10% NaOH solution for three times, and finally the filter cake is washed with water again. Wash with 150ml of water 3 times. Concentrated to dryness, then dissolved in 250ml of ethyl acetate and 5g of activated carbon, stirred for 0.5h, filtered and concentrated to dryness and recrystallized to obtain the product Wherein the R group is a hydrogen atom,...

Embodiment 2

[0028] Select methacrylic acid for esterification

[0029] Mix 150g of borneol and 450g of methacrylic acid in a 1L four-necked bottle, add 25ml of boron trifluoride ether, and 15g of hydroquinone, dissolve in 500ml of n-octane solution, stir, at a temperature of 110-120 Reflux between ℃, send samples after 2h of reaction, use HPLC to detect, stop the reaction when the content of borneol is less than 3g;

[0030] Cool to 90°C, add 5g of activated carbon for 1 hour of reflux, then cool down to 60°C while hot suction filtration, wash the filter cake with 250ml of water for 3 times, and then use 250ml of 10% NaOH solution for 3 washes, and finally use Wash with 250ml of water 3 times. Concentrated to dryness, then dissolved in 250ml of ethyl acetate and 5g of activated carbon, stirred for 0.5h, filtered and concentrated to dryness and recrystallized to obtain the product Wherein the R group is methyl, the product yield is 89.2%.

Embodiment 3

[0032] Select Ethacrylic Acid for Esterification

[0033] Add 200g of borneol and 600g of ethyl acrylic acid to a 1L four-necked bottle and mix, add 15ml of 98% concentrated sulfuric acid, 20g of m-methoxyphenol, dissolve in 550ml of n-heptane solution, stir, at a temperature of 110- Reflux between 120°C, send samples after 2 hours of reaction, use HPLC to detect, stop the reaction when the content of borneol is less than 4g;

[0034] Cool down to 90°C, add 8g of activated carbon and reflux for 1 hour, then cool down to 60°C while hot suction filtration, wash the filter cake with 250ml of water 3 times, and then use 250ml of 10% NaOH solution for 3 washes, and finally use Wash with 250ml of water 3 times. Concentrated to dryness, then dissolved in 250ml of ethyl acetate and 5g of activated carbon, stirred for 0.5h, filtered and concentrated to dryness and recrystallized to obtain the product Wherein the R group is ethyl, the product yield is 90.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com