Preparation method of microwave absorbing rubber composite material

A composite material and microwave absorption technology, which is applied in the field of preparation of functional polymer materials, can solve the problem that the microwave reflectivity does not change significantly, and achieve the effect of improving microwave absorption performance and absorption frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

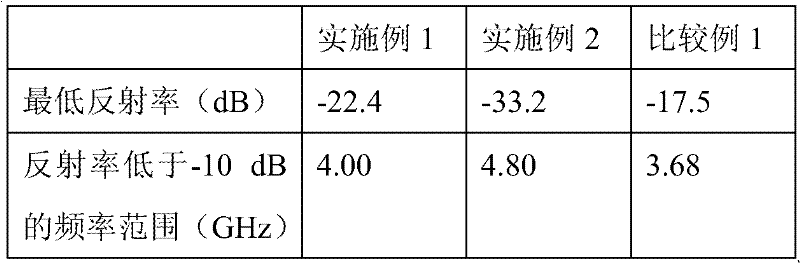

[0029] Embodiment 1-2 (adopting one-time blending method to prepare)

[0030] By the formula of table 1, hydrogenated nitrile butadiene rubber, ethylene propylene rubber, multi-walled carbon nanotubes, carbonyl iron powder, acrylic acid (AA) and dicumyl peroxide (DCP) were mixed for 20min on a two-roller open mill, and controlled The roll temperature is lower than 60°C, and then vulcanized at 170°C for 20min to obtain a rubber composite material for microwave absorption. The complex permittivity and complex permeability of the material are tested by the transmission-reflection method, and converted into the microwave reflectivity of a microwave-absorbing rubber composite material with a certain thickness.

Embodiment 3-5

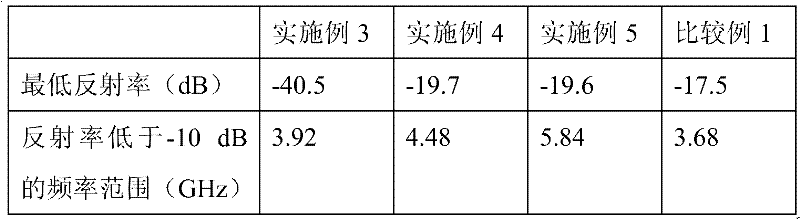

[0039] Embodiment 3-5 (prepared by segmental blending method)

[0040] According to the formula in Table 3, hydrogenated nitrile rubber, multi-walled carbon nanotubes and dicumyl peroxide were mixed for 10 minutes on a two-roll mill, and the controlled roll temperature was lower than 60°C to obtain hydrogenated nitrile rubber / carbon nanotubes Masterbatch;

[0041] According to the formula in Table 3, mix ethylene-propylene rubber, carbonyl iron powder and acrylic acid on a two-roll mill for 10 minutes, control the temperature of the rollers below 60°C, and then heat-press them on a flat vulcanizer at 120°C for 2 hours, and then heat them on a double-roll mill. Mix with dicumyl peroxide for 2 minutes on the open mill, and control the roll temperature below 60°C to obtain ethylene-propylene rubber / carbonyl iron powder masterbatch;

[0042] Mix the hydrogenated nitrile rubber / carbon nanotube masterbatch and ethylene propylene rubber / carbonyl iron powder masterbatch obtained above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com