Method for chrome-nickel-molybdenum composite electroplating of thread surface of pipe joint special for oil well pipe

A composite electroplating and thread surface technology, applied in the field of metal pipe surface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

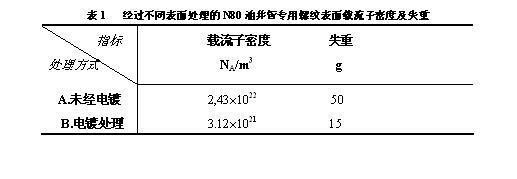

Image

Examples

Embodiment

[0026] In an embodiment, its specific process and steps are as follows:

[0027] (1) Design the raw material formula of the composite electroplating solution

[0028] CrCl 3 .6H2O 20 g, Na 2 MoO 4 .2H 2 O 10g,

[0029] NiCl.6H 2 O 50 g, Na 4 P 2 o 7 .10H 2 O 30 g,

[0030] N 2 h 4 .H 2 SO 4 1g, NaHCO 3 10g,

[0031] CH 3 COONa.3H 2 O 10 g, SrSO 4 1g,

[0032] Deionized water 1L;

[0033] The above electroplating solution uses H 2 SO 4 Adjust its pH value to 4~5; where Cr 3+ / Ni 2+ / MoO 4 2- The equivalent concentration ratio is 3 / 5 / 2; the electroplating solution is made of chemically pure reagents and deionized water;

[0034] (2) Process of composite electroplating

[0035] (a) Pre-treat the surface of the threaded surface of the oil well pipe special pipe joint to be treated by conventional methods. The process flow is: flowing cold water washing—chemical degreasing—hot water washing—flowing cold water washing—weak cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com