Multi-stage side heater in vertical gradient freezing crystal growing furnace

A vertical gradient solidification, crystal growth furnace technology, applied in crystal growth, single crystal growth, self-solidification and other directions, can solve problems such as inconvenience in production and equipment maintenance, achieve good symmetry and stability, easy to reclaim, improve The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

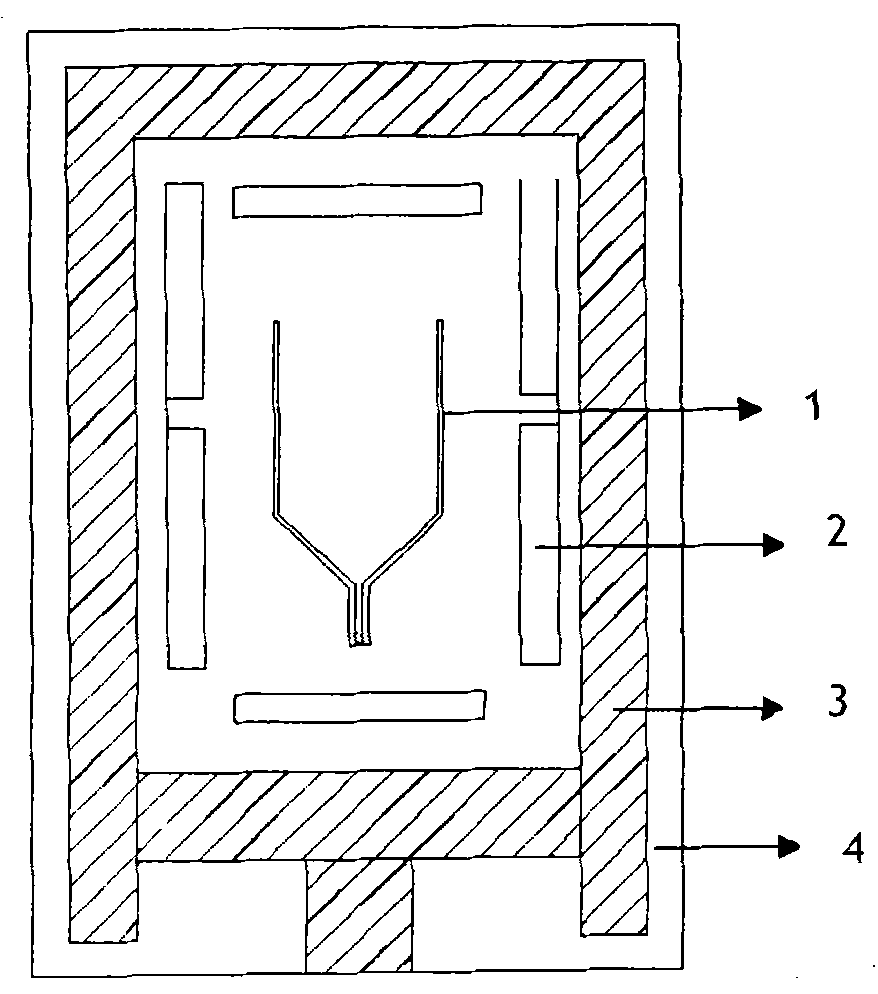

Embodiment Construction

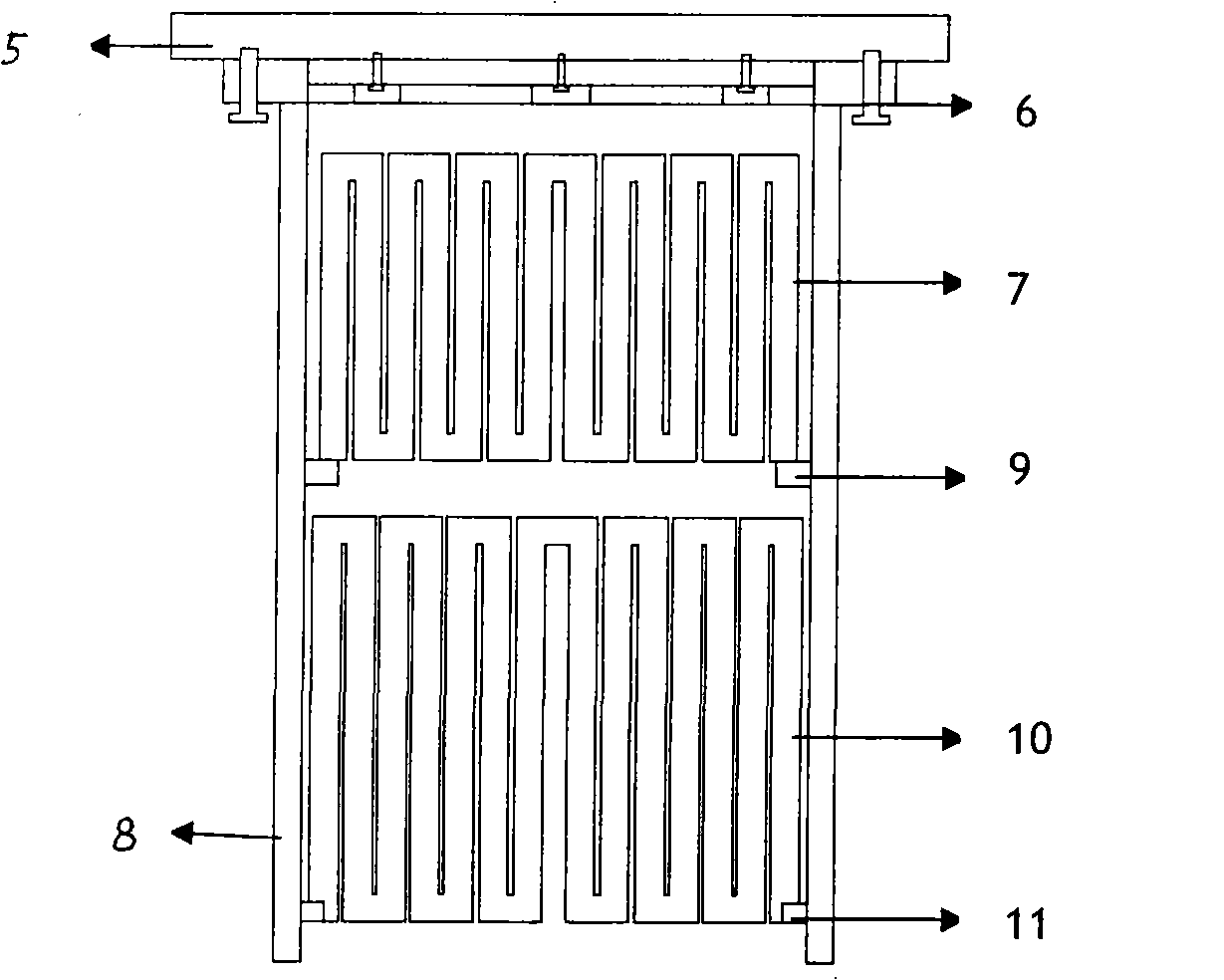

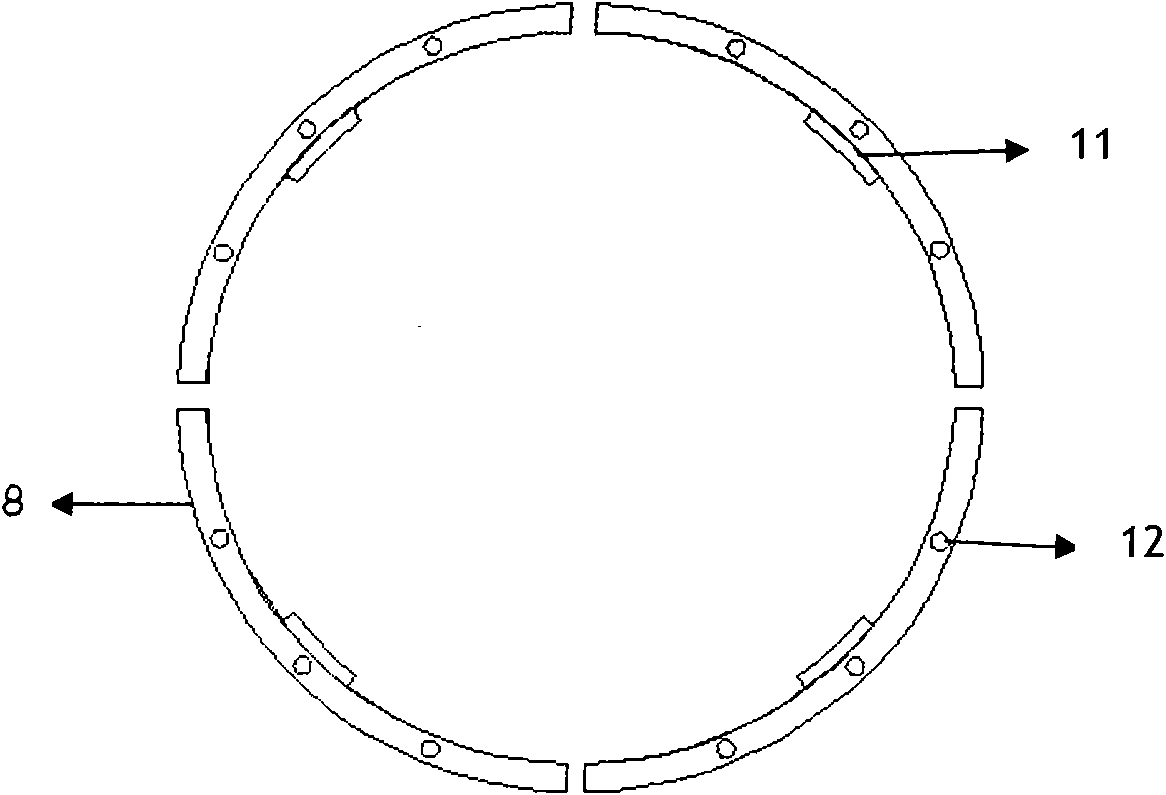

[0018] Installation scheme 1: Connect the upper heater directly to the graphite electrode, and the lower heater is pre-installed in the graphite cylinder composed of two half-cylindrical graphite cylinders, and connect the graphite sleeve to the electrode. In order to ensure the safety of the graphite electrode and prevent the graphite electrode from being stressed, two symmetrical BN blocks are installed on the graphite sleeve to support the upper heater, the lower heater is supported and connected by graphite blocks, and the graphite sleeve is fixed on the Put it on the furnace cover, so that when the furnace cover is raised or lowered by the screw on the outside of the furnace body, the graphite sleeve is moved out or put into the furnace body together with the heater.

[0019] Installation plan 2: use 1 / 4 cylindrical long plate to connect the upper and lower heaters, and use graphite blocks to support each heater at the connection part. After the installation is completed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com