Fuel-water ratio control method for supercritical and ultra supercritical unit

An ultra-supercritical unit and control method technology, which is applied in the combustion method, combustion control, and fuel supply adjustment, etc., can solve the problems that affect the stability of the unit, have a large impact, and the variable load rate is difficult to achieve, and achieve system stability. The effect of unaffected, stable main steam temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

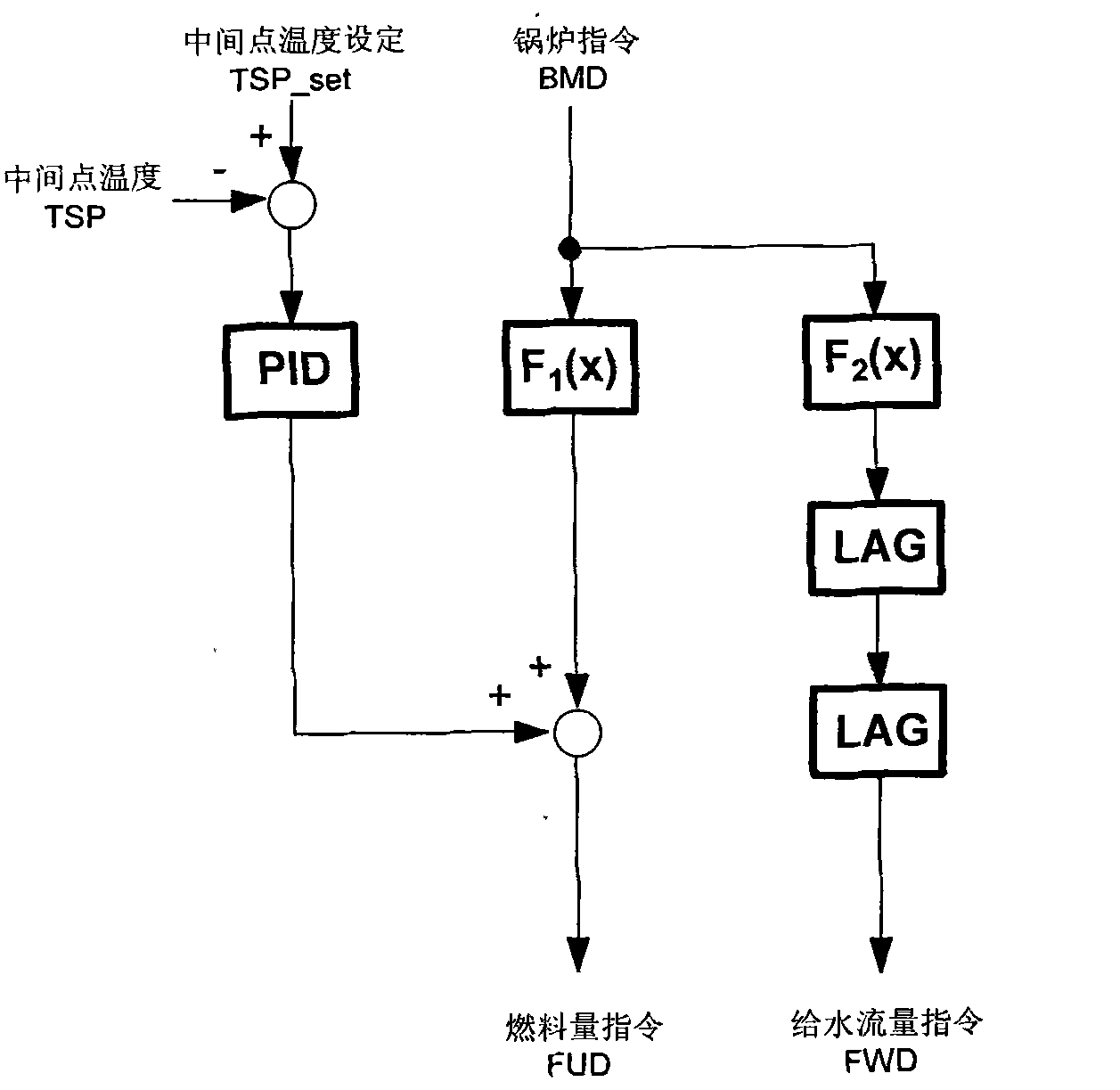

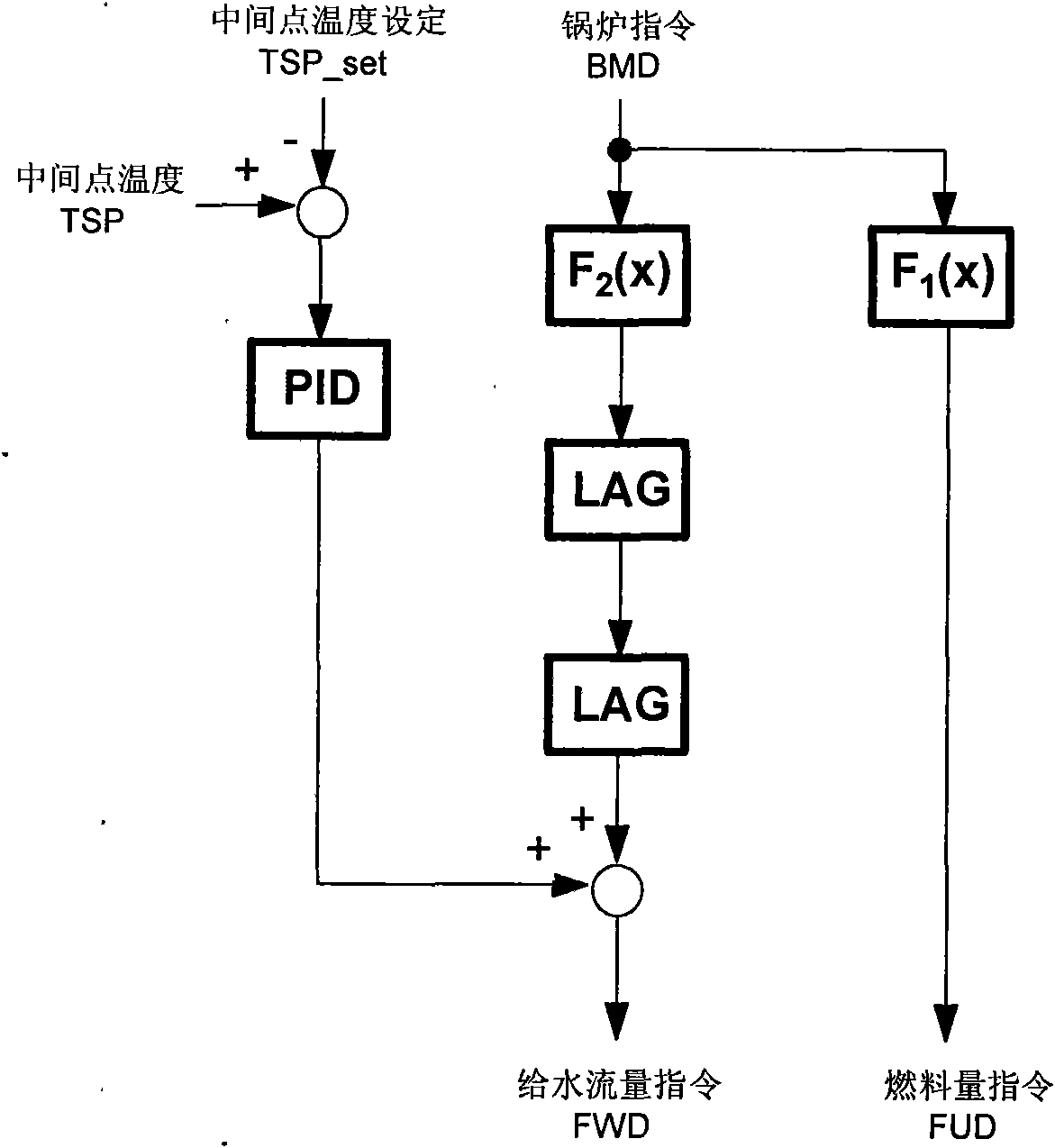

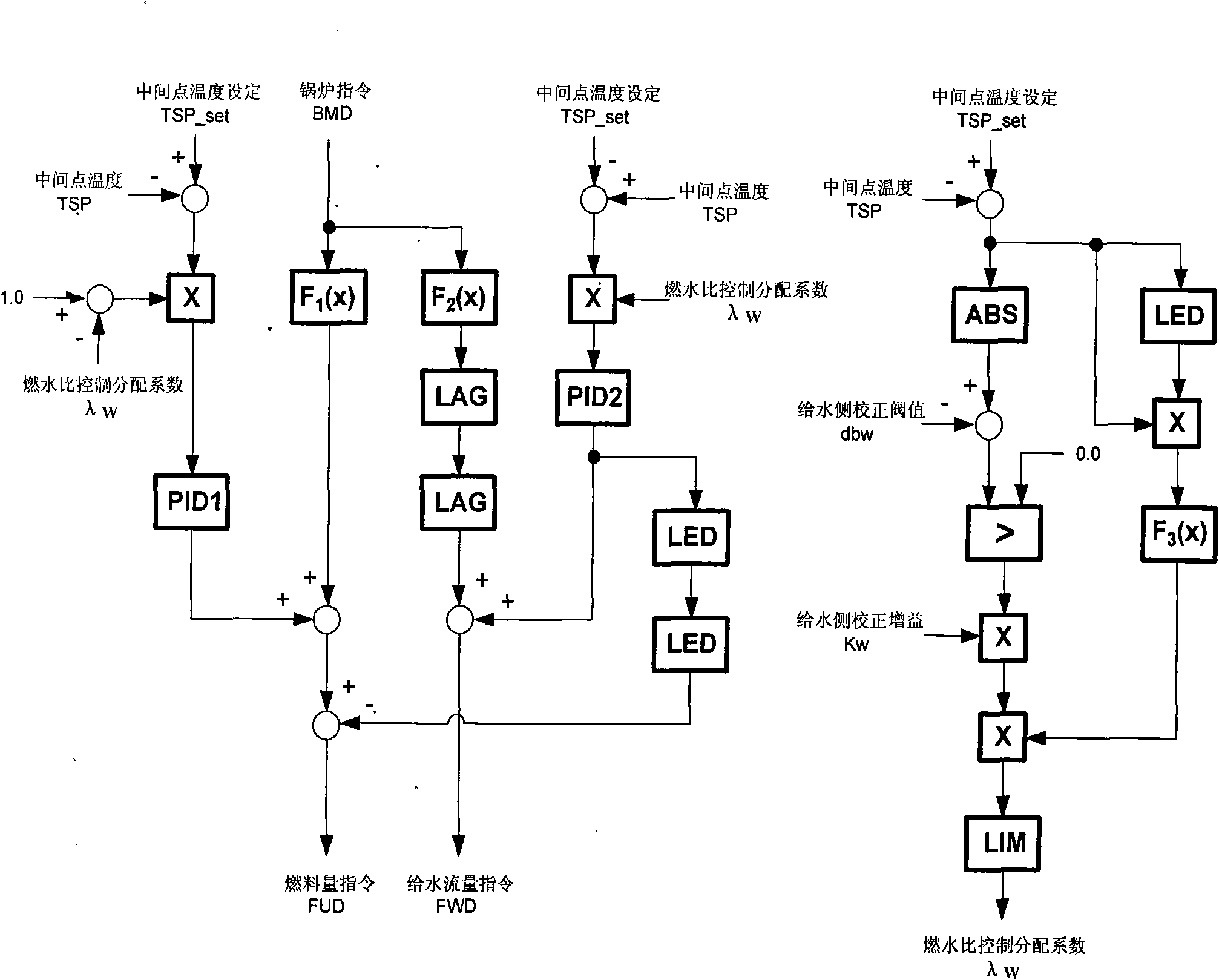

Method used

Image

Examples

Embodiment Construction

[0039] Two 660MW supercritical units in a power plant adopt the control scheme of this patent, and the specific parameters are set as:

[0040] Feed water side temperature regulator PID1:

[0041] Fuel side thermostat PID2:

[0042] The two-order inertia link of BMD→FWD:

[0043] The two-order actual differential link in the decoupling loop from the PID regulator on the water supply side to the fuel command:

[0044]

[0045] Water supply side correction threshold dbw: 4.0;

[0046] Water supply side correction gain Kw: 0.2;

[0047] The actual differential link to calculate the rate of change of temperature difference at the intermediate point:

[0048] The function F1(x) of BMD→FUD:

[0049] BMD

0

240

320

400

460

540

600

660

750

F1(x)

0

96.48

128.64

160.8

185.84

219.24

244.2

269.28

306

[0050] The function F2(x) of BMD→FWD:

[0051] BMD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com