Anti-hopping vacuum contactor of high-speed frame-type repulsion mechanism

A technology of vacuum contactor and repulsion mechanism, applied in high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., can solve problems such as long contact time, scattering, and coil damage, and achieve reliable operation, energy saving, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

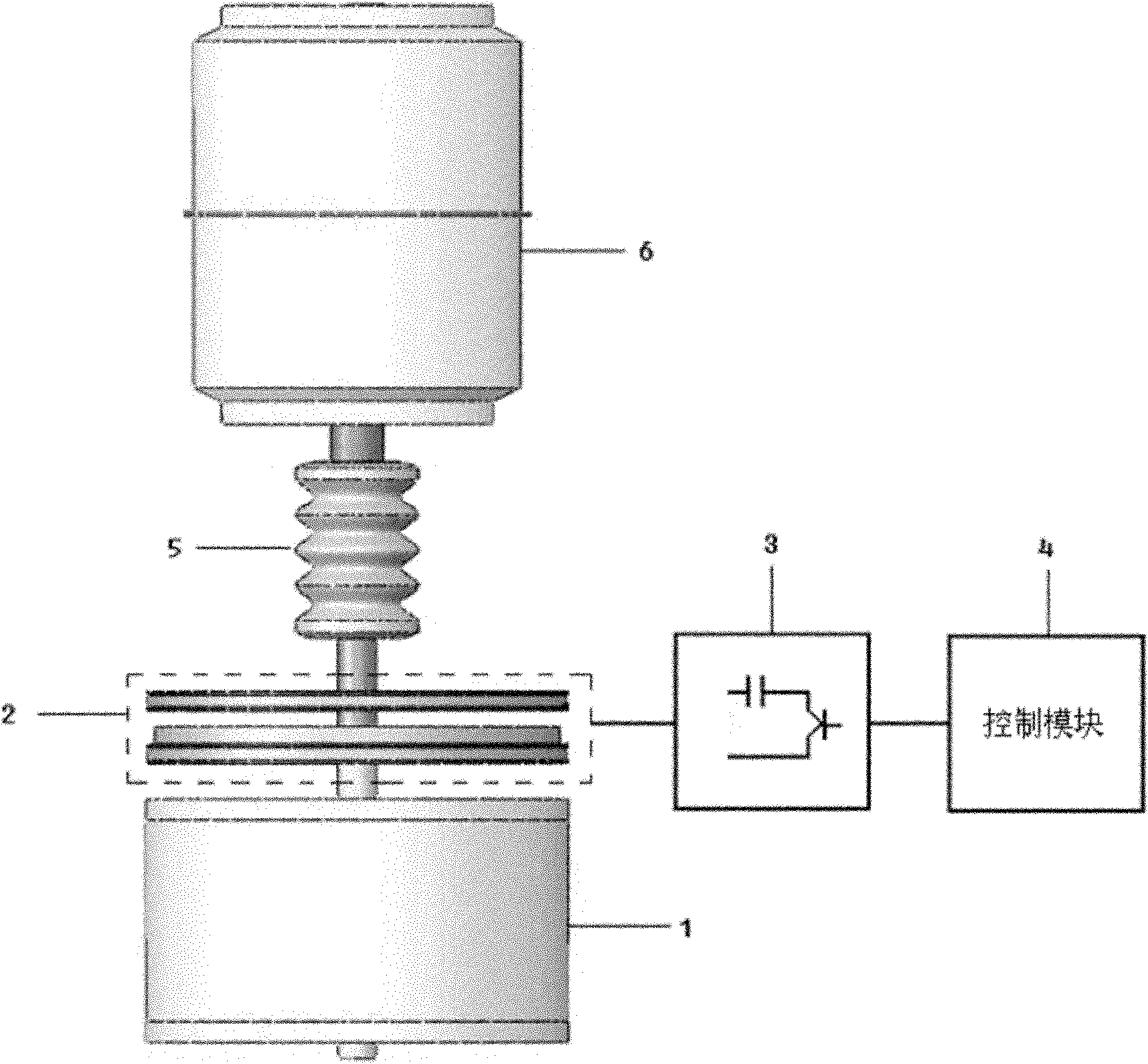

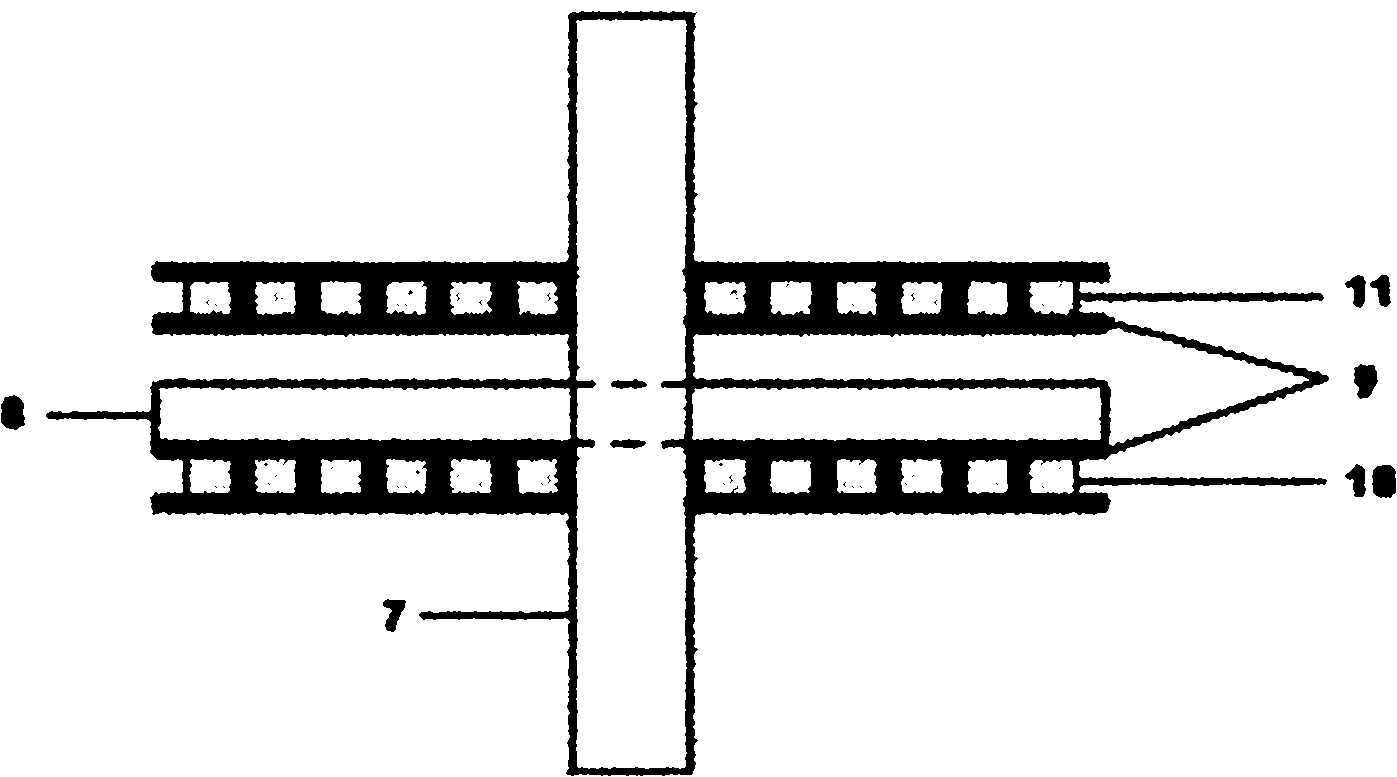

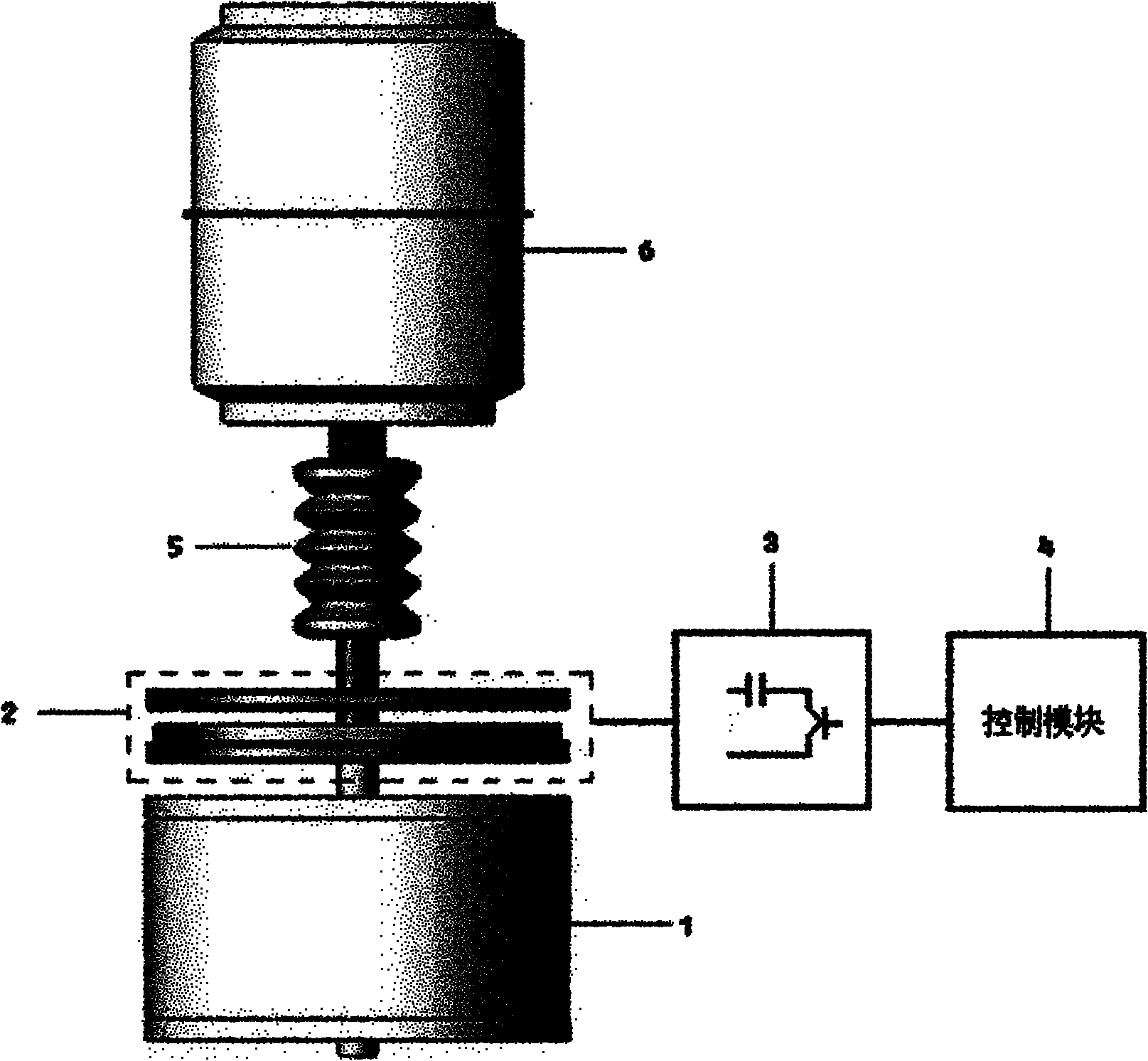

[0012] of the present invention figure 2 The middle frame type high-speed repulsion mechanism is typically used for figure 1 The frame type repulsion mechanism in. according to figure 1 The schematic diagram of the functional structure and figure 2 As shown in the internal structure diagram of the frame-type high-speed repulsion mechanism, 1 permanent magnet mechanism is connected with 2 frame-type repulsion mechanism, 2 is connected with 5 insulating pull rods, 5 is connected with 6 vacuum interrupter. 2. The 11 opening coils and 10 closing coils in the frame-type repulsion mechanism are respectively connected to the 3 capacitor pulse discharge device, and the 3 capacitor pulse discharge device is connected to the 4 control module. When the contactor needs to be closed, the 4 control module sends a command to make the 3 capacitor pulse discharge device discharge the 10 closing coils in the 2 frame repulsion mechanism, and the 8 copper discs in the 2 frame repulsion mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com