Method for preparing cerium carbonate and method for preparing cerium oxide powder

A technology of cerium carbonate and powder, which is applied in the field of cerium carbonate powder, can solve the problems of falling into danger, insufficient cerium carbonate yield or productivity, and achieve the effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Under normal pressure (1 atm) and normal temperature (RT), 43.4 g of cerium nitrate and 18 g of urea (3 equivalents) were mixed, the temperature of the reaction mixture was raised to 140° C., and then kept at this temperature for 16 hours. Then, the reaction mixture was slowly cooled and diluted with water to complete the reaction, and then vacuum-dried at 80° C. for 24 hours to prepare cerium carbonate.

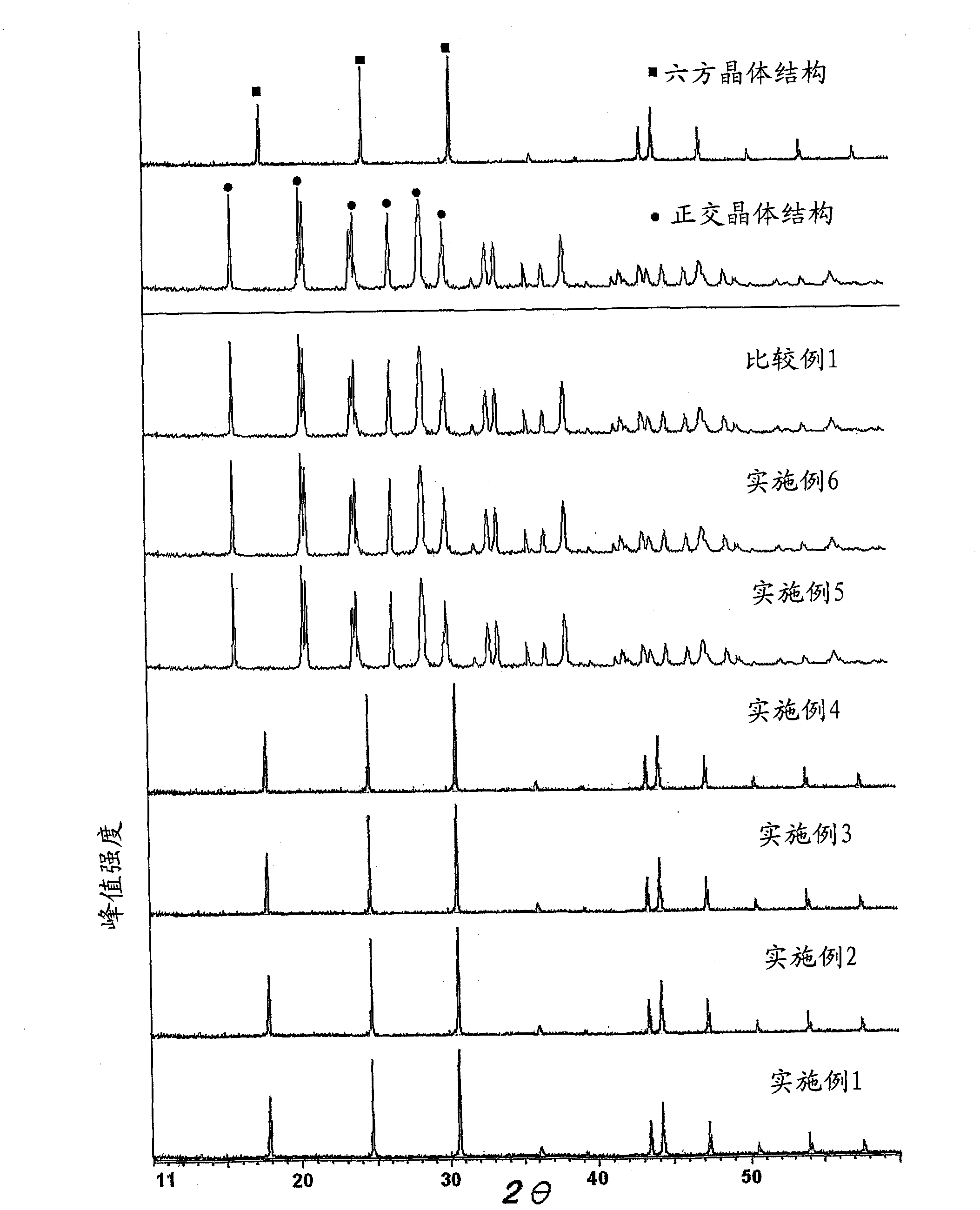

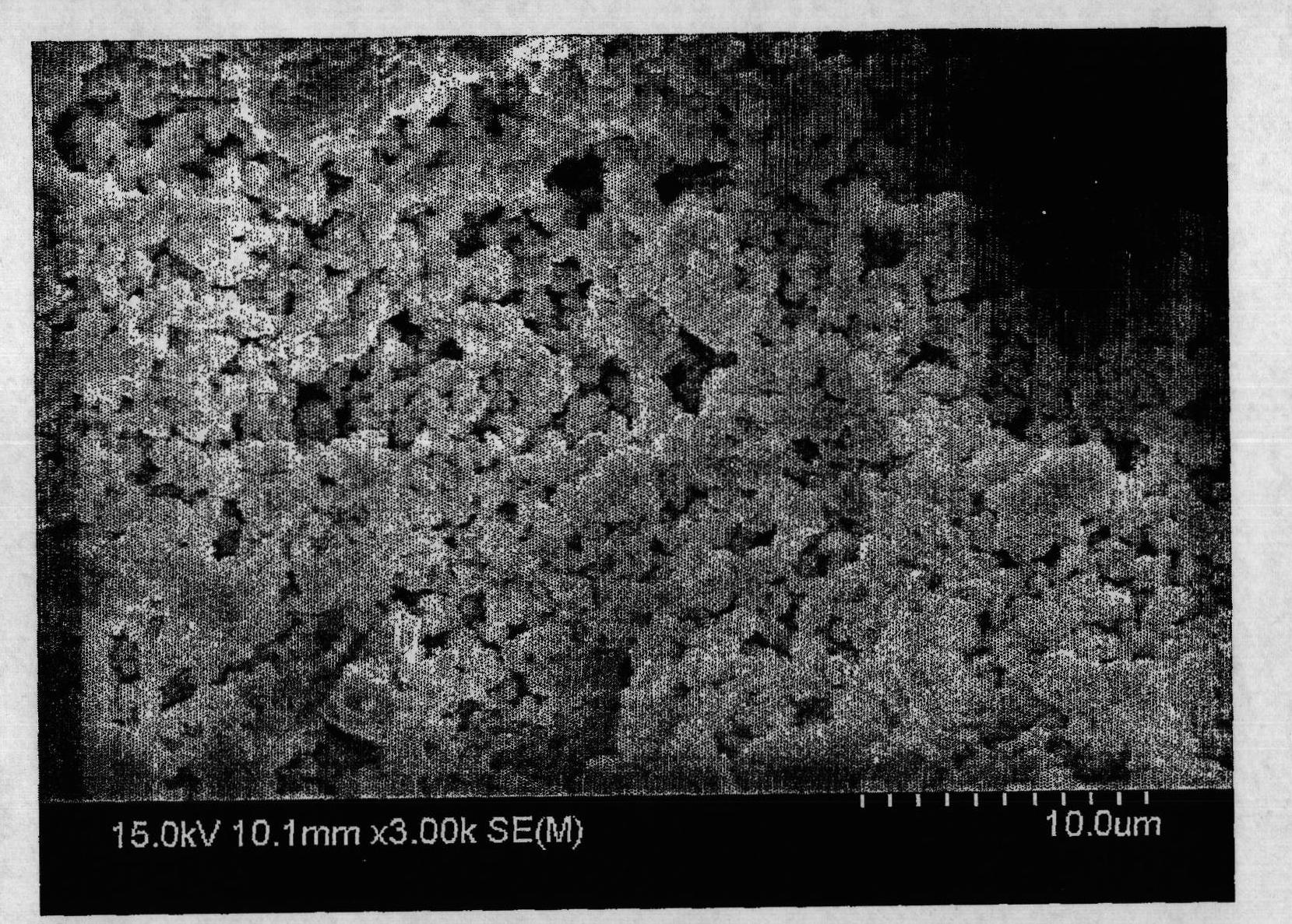

[0066] Carry out XRD analysis and SEM analysis to gained cerium carbonate, and use respectively figure 1 and figure 2 Display its result. These results demonstrate the preparation of orthorhombic and hexagonal cerium carbonate powders.

[0067] And it is assumed that the part where the temperature is kept constant during the heating process is the urea decomposition reaction temperature, which was measured and shown in Table 1 below.

[0068] The final yield of cerium carbonate was then measured and shown in Table 1 below.

Embodiment 2-6

[0070] As shown in Table 1 below, except that the equivalent ratio of cerium nitrate to urea, the heating temperature and the addition of nitric acid were changed, cerium carbonate was prepared in the same manner as in Example 1. As for nitric acid, a 63% aqueous solution of nitric acid was used.

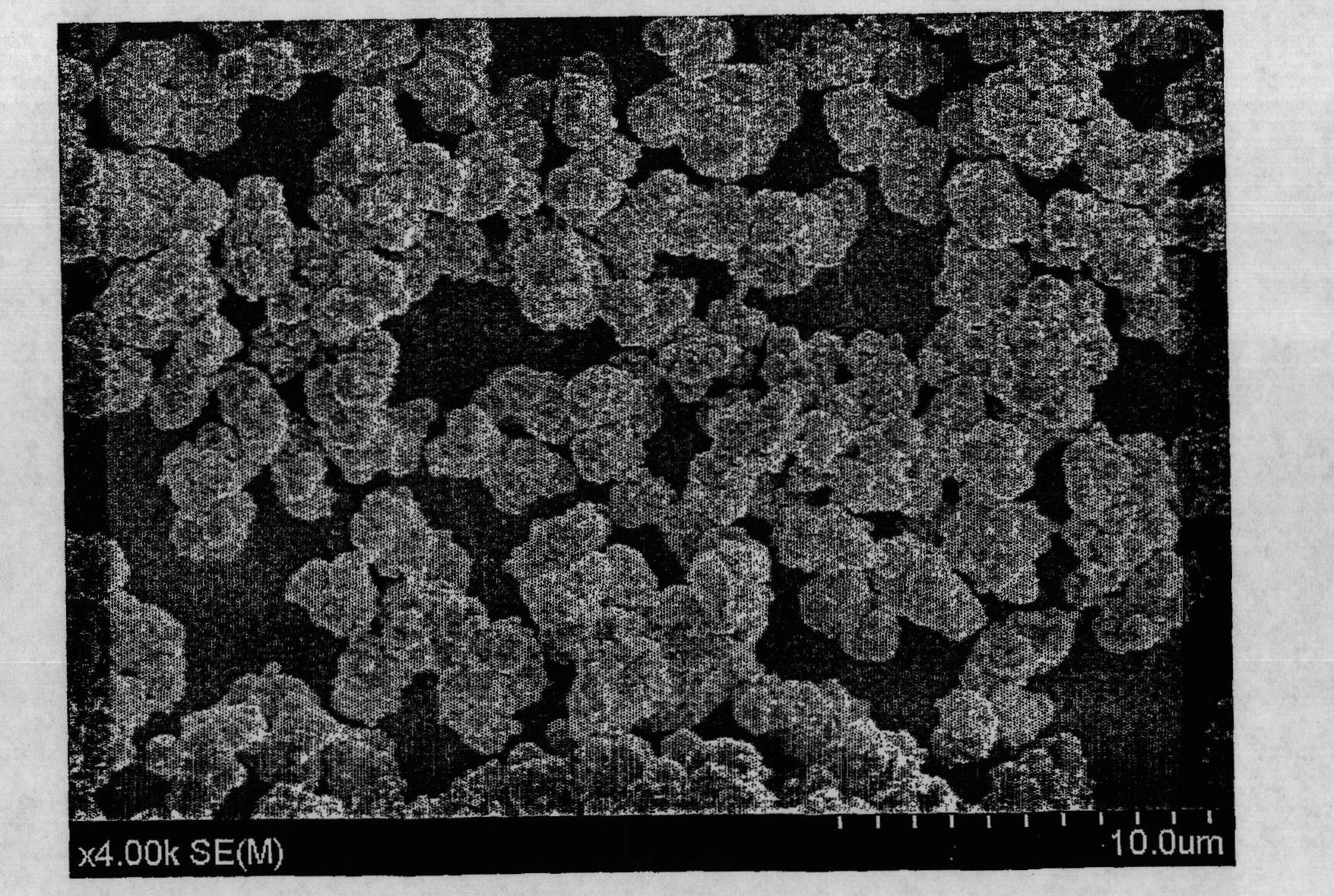

[0071] Carry out XRD analysis to gained cerium carbonate respectively, the result is expressed in figure 1 and the relevant data are shown in Table 1 below. And, the cerium carbonate prepared in embodiment 2-5 carries out SEM analysis respectively and the result is expressed in Figure 3-6 middle.

Embodiment 7

[0073] Cerium carbonate was prepared by the same method as in Example 1 under the reaction conditions shown in Table 1 below, except that the reaction temperature was adjusted to 100° C. and the reaction time was adjusted to 3 hours.

[0074] Gained cerium carbonate is carried out XRD analysis and the result is shown in Figure 7 The relevant data are shown in Table 1 below. It is proved by XRD analysis that the cerium carbonate in Example 7 is a mixture of orthorhombic cerium carbonate and hexagonal cerium carbonate, and the volume ratio of orthorhombic: hexagonal is 2.5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com