Regenerated solution of alkaline copper etching solution and method for increasing etching speed thereof

A technology for copper etching and regenerating solution, which is applied in the field of regenerating solution of alkaline copper etching solution by accelerating agent, can solve the problems of affecting the etching quality, the service life of the productive regenerating solution, and the inability to guarantee the stable performance of the etching regenerating solution, so as to improve the use of the regenerating solution. Longevity, improved etching rate, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

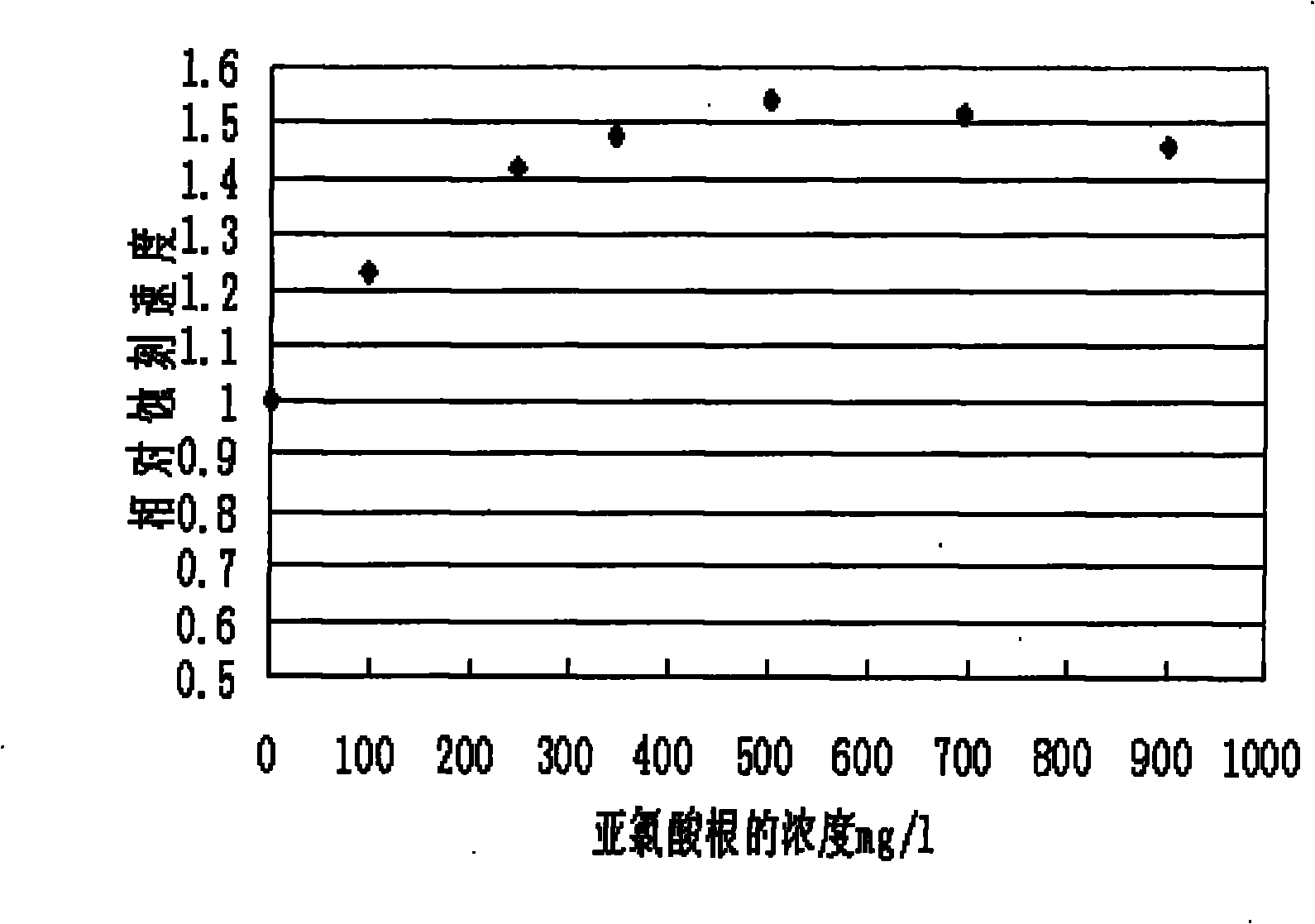

[0030] Taking the etching rate of the alkaline copper chloride etching regeneration solution that has been recycled for about half a year as the baseline value, this rate is set as a relative value of 1 for comparison. Then, by adding sodium chlorite to the etching regeneration solution, investigate the relative speed of the regeneration solution after adding sodium chlorite and the original regeneration solution.

[0031] The existing alkaline copper etch regeneration solution used to determine the baseline value consists of:

[0032] Cu 2+ 135~165g / L

[0033] Cl - 175~195g / L

[0034] NH 3 Adjust to PH8.2~8.6

[0035] NH 4 HCO 3 20~30g / L

[0036] (NH 4 ) 2 HPO 4 0.5~2g / L

[0037] Thiourea or dithiobiurea 0.1~1g / L

[0038] The etching conditions are as follows: the temperature is 50±2° C., the pH=8.3˜8.6 and the pressure i...

Embodiment 2

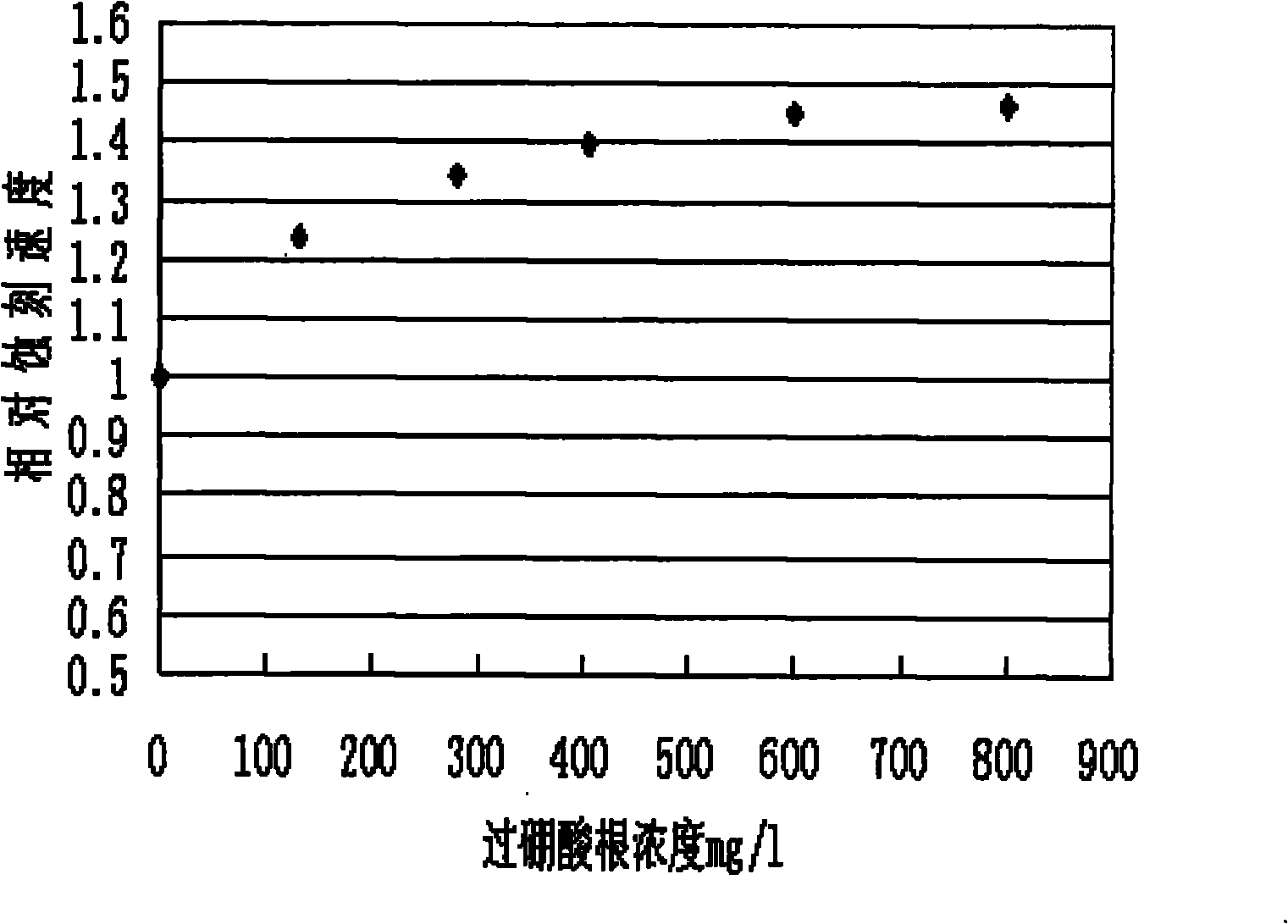

[0041] It is basically the same as Example 1, except that the speed-accelerating agent added to the alkaline copper chloride etching regeneration solution is sodium perborate. Carried out 5 experiments by increasing the concentration of sodium perborate added to the above-mentioned alkaline copper chloride etching regeneration solution, the experimental results can be found in figure 2 . figure 2 Test results are shown for each concentration tested, expressed as relative etch rates. The test results show that when the added perborate ion is in the concentration range of 100mg / L-900mg / L, the etching speed is improved compared with the original regeneration solution. When the added perborate ion concentration reaches 400mg / L, the etching The speed increased significantly, and the relative etching speed reached 1.4. When the concentration exceeds 400mg / L, the etching rate increases very slowly. When the concentration reaches 600mg / L, the relative etching rate is 1.45, which m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com