Vacuum ice-making, refrigeration and cooling system for mine shaft

A vacuum and cold technology, applied in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc., can solve the problems of high operating cost, poor reliability, complex structure, etc., and achieve the effect of large investment, large weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

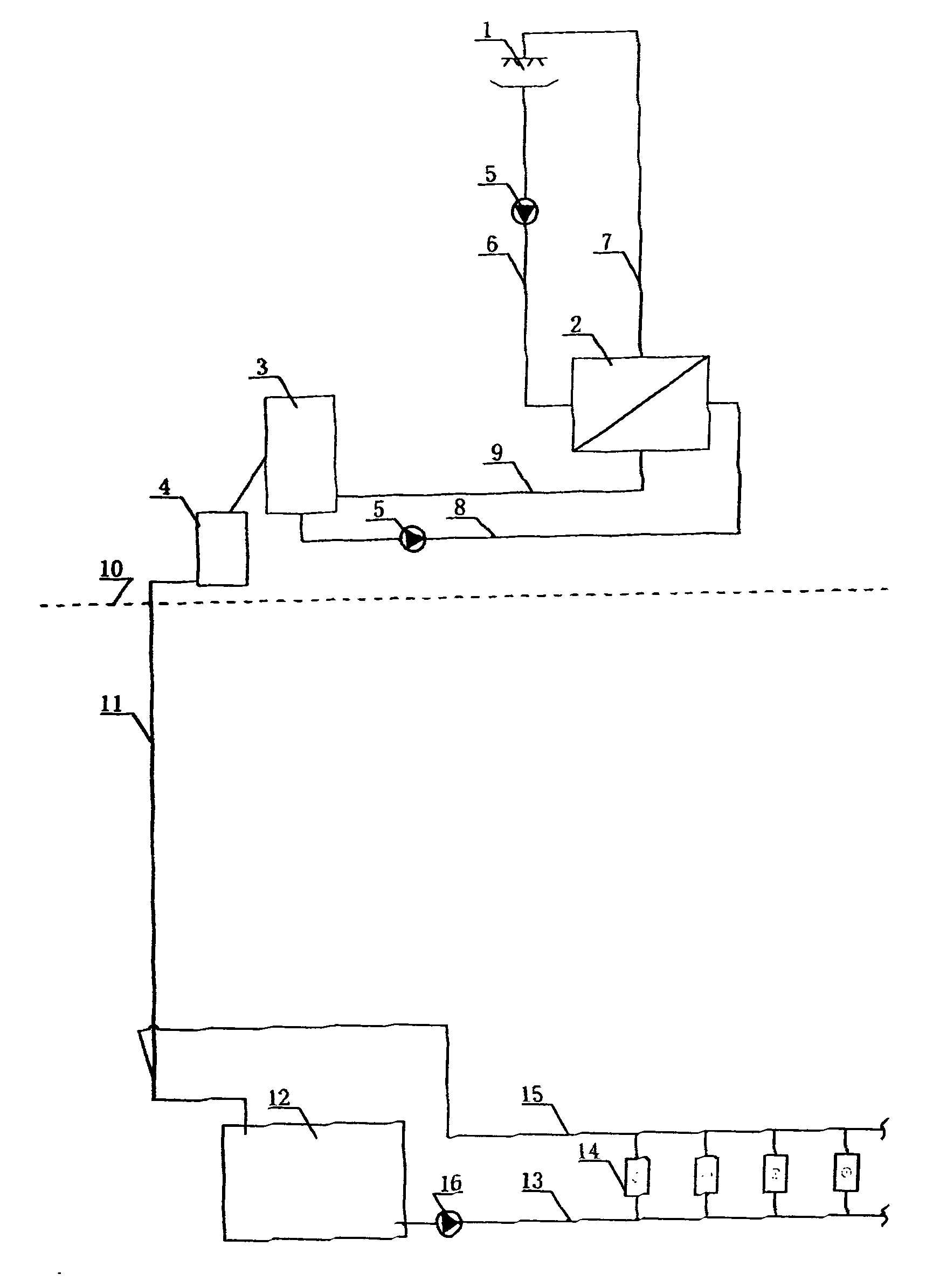

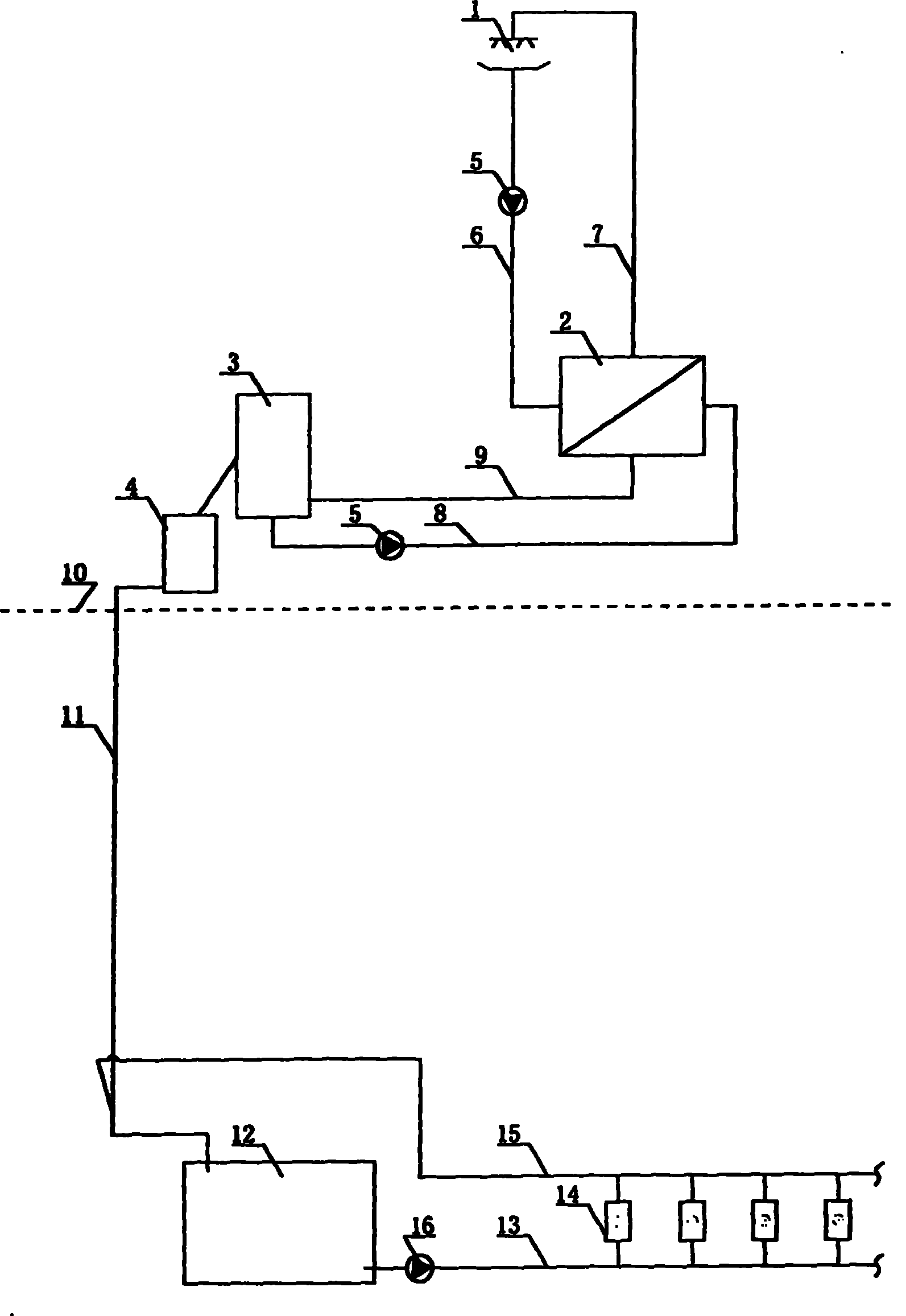

[0013] With reference to accompanying drawing, the present invention is divided by surface line 10 on the figure, above surface line 10 is ground, below is underground. The ground part is mainly composed of cold water circulation system and cooling water heat removal circulation system; the underground part is composed of underground ice melting pool 12, ice water pump 16, cold water supply pipe 13, working surface air cooler 14, and cold water return pipe 15. Refrigeration cooling cycle system.

[0014] The cooling tower 1 and the chiller 2 form a cooling water heat removal cycle system through the cooling water supply pipe 6, the water pump 5 and the cooling water return pipe 7, and the chiller 2 and the vacuum ice machine 3 pass through the chilled water supply pipe 9 and the chilled water return pipe 8. The water pump 5 forms a cold water circulation system. The vacuum ice maker 3 is connected to the underground ice melting tank 12 through the ice delivery device 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com