Coal-saving stove core

A furnace core and core body technology, applied in the field of dry stoves, can solve the problems of inefficient coal saving, unsatisfactory effect, and low thermal efficiency, and achieve the effects of burning less coal, improving coal combustion efficiency, and reducing waste residue and garbage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

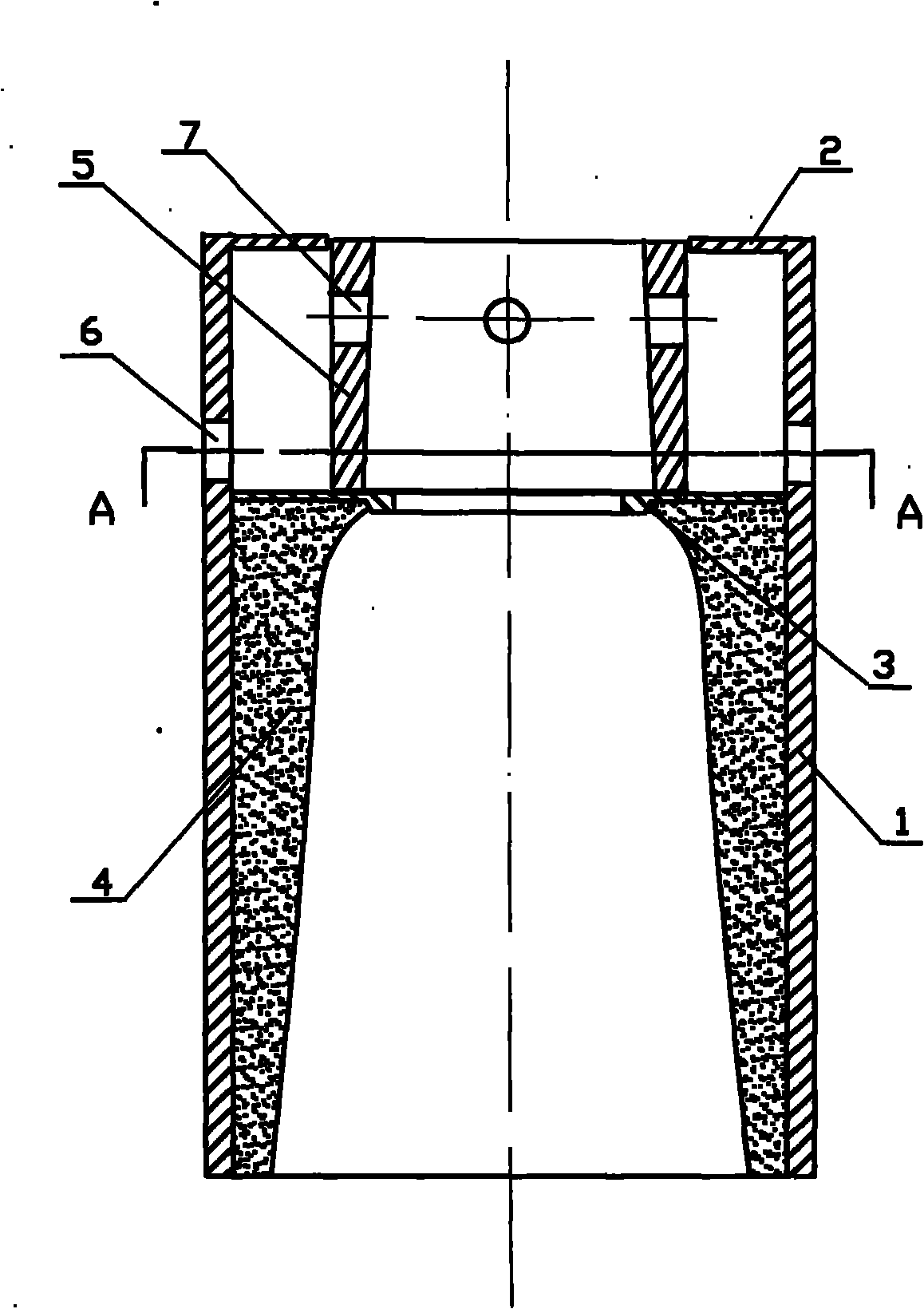

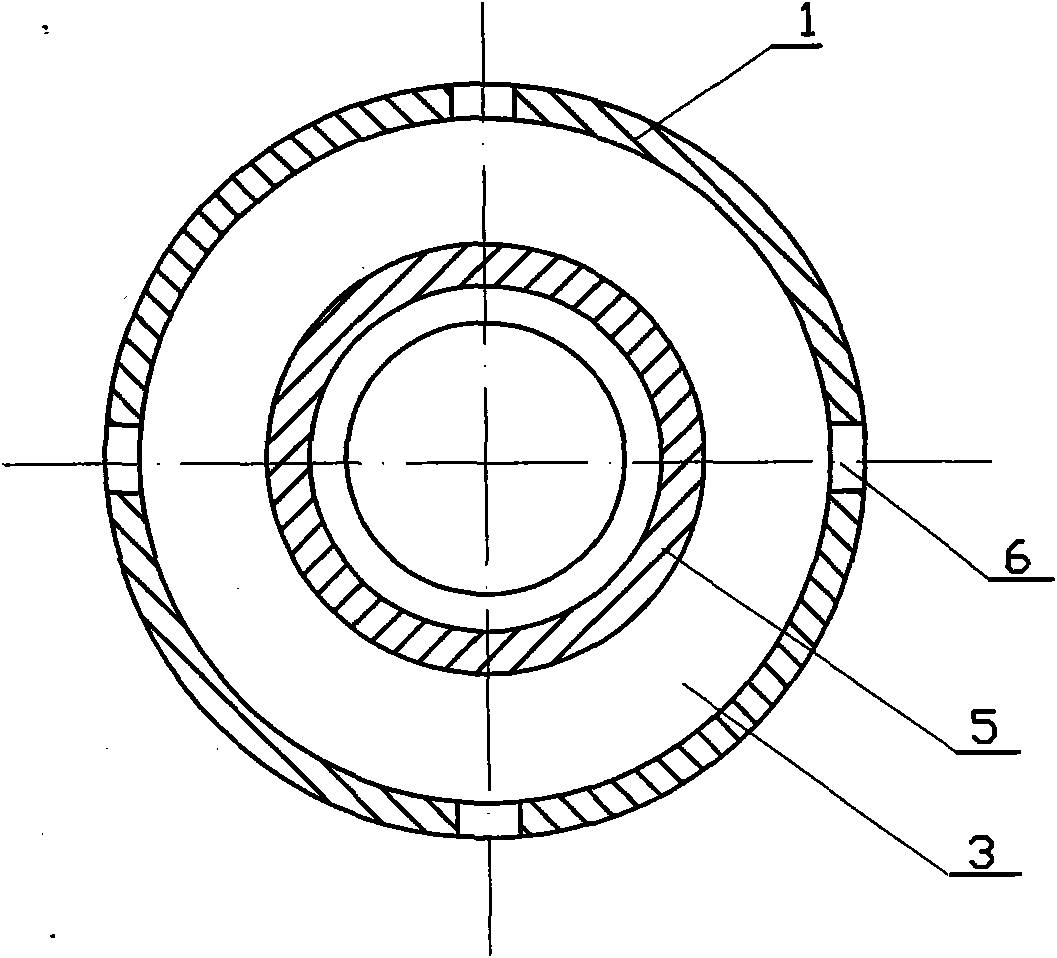

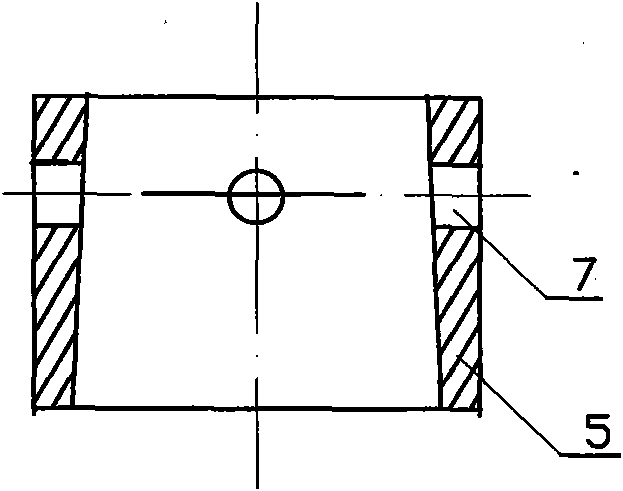

[0014] one attached figure 1 The coal-saving furnace core is composed of a core body 1, an airtight ring 2, a spacer ring 3, a hearth 4, and a fire tube 5. The core body 1 is cylindrical, the top of which is connected to the airtight ring 2, and the upper waist has a vent 6 The airtight ring 2 is annular, and its outer ring is fixed on the core body 1; the spacer ring 3 is annular, covered on the furnace 4, and its outer ring is fixed on the inner upper waist of the core body 1, and the size of the inner ring is the same as the burner of the furnace hearth 4 Consistent; the hearth 4 is vertical, close to the core 1; the fire beam tube 5 is a cast iron cylinder with a thick top and a thin bottom. There are 4 air vents on the upper waist of the core body, and 8 air inlets on the upper waist of the fire beam tube 5; a fire sealing cover is provided.

[0015] The core body 1 of the furnace core has a diameter of 240mm and a height of 350mm; the outer diameter of the spacer 3 is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com