Tri-differential confocal microscope imaging method with high axial resolution and imaging device

A confocal microscope and differential confocal technology, applied in microscopes, optics, instruments, etc., can solve the problems of low utilization of light energy, difficulty in ensuring the stability of pinhole displacement, and high requirements for the use environment, and achieve the use environment. Less demanding, improved axial resolution, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

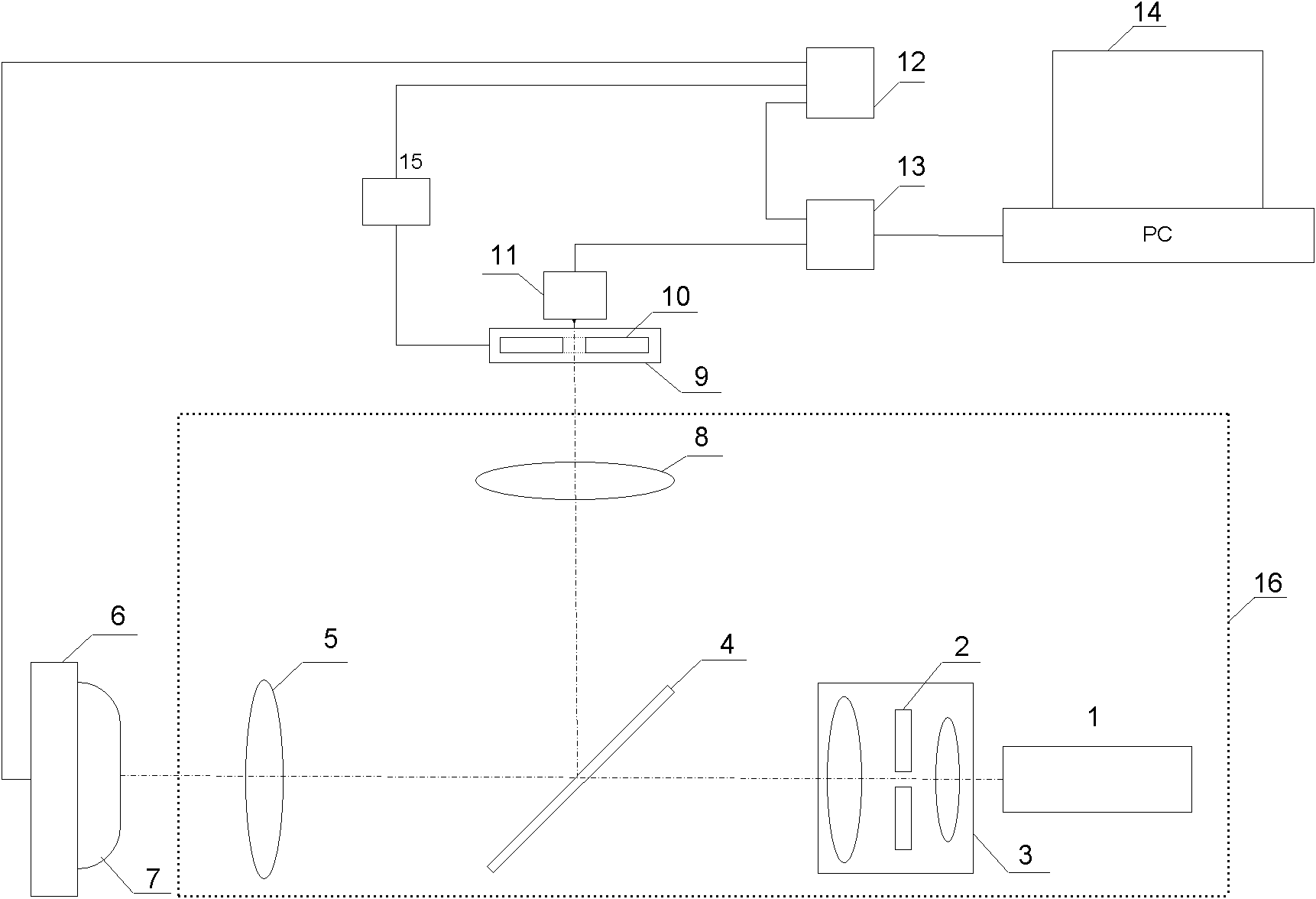

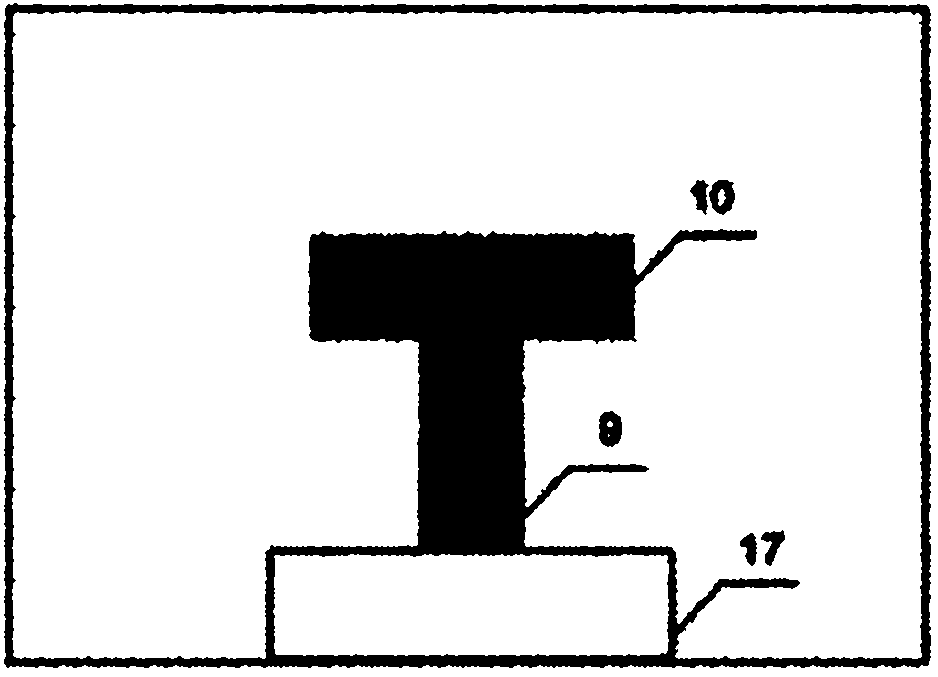

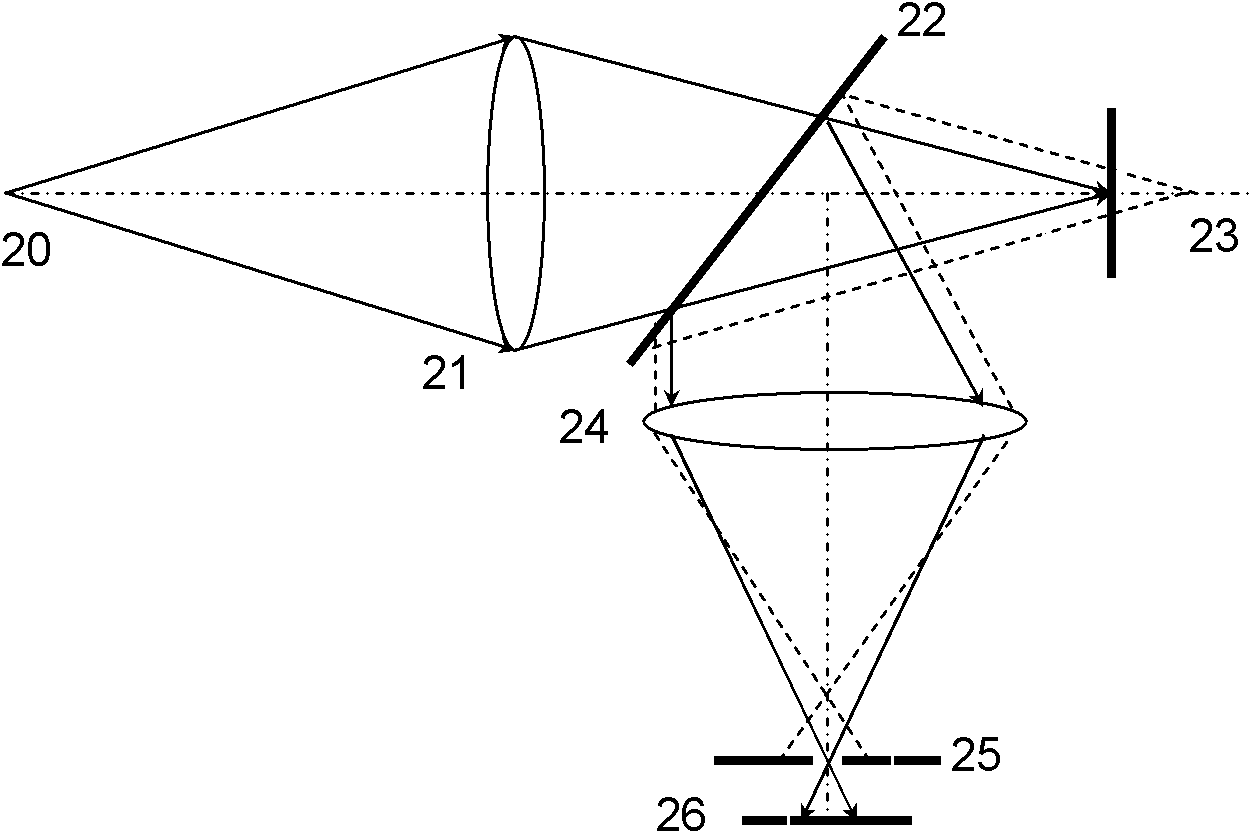

[0027] The specific implementation of the present invention is as follows: the pinhole 10 at the photodetector is bonded to one end of the pinhole axial micro-displacement device 9 with an adhesive. In this embodiment, the pinhole axial micro-displacement device 9 uses a piezoelectric ceramic scanner. The other end of the pinhole axial micro-displacement device 9 is bonded to the substrate 17. A pinhole axial micro-displacement device 9 controls the movement of the pinhole 10 along the axial direction at the light detection site. First, the signal synchronization device 12 sends a control signal. The signal synchronization device in this embodiment is a synchronization circuit board, which controls the pinhole axial micro-displacement drive device 15 to generate a drive signal. In this embodiment, the pinhole axial micro-displacement driving device 15 is a high-voltage amplifier. The high-voltage amplifier generates a driving voltage signal to drive the pinhole axial micro-disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com