Spraying type solution evaporation and concentration method

A technology of evaporation concentration and solution concentration, which is applied in the direction of spray evaporation, etc., can solve the problems of complex structure of forced circulation evaporator, large investment of evaporation device system, high material requirements, etc., and achieve excellent anti-fouling performance, high vapor-liquid separation efficiency, The effect of high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

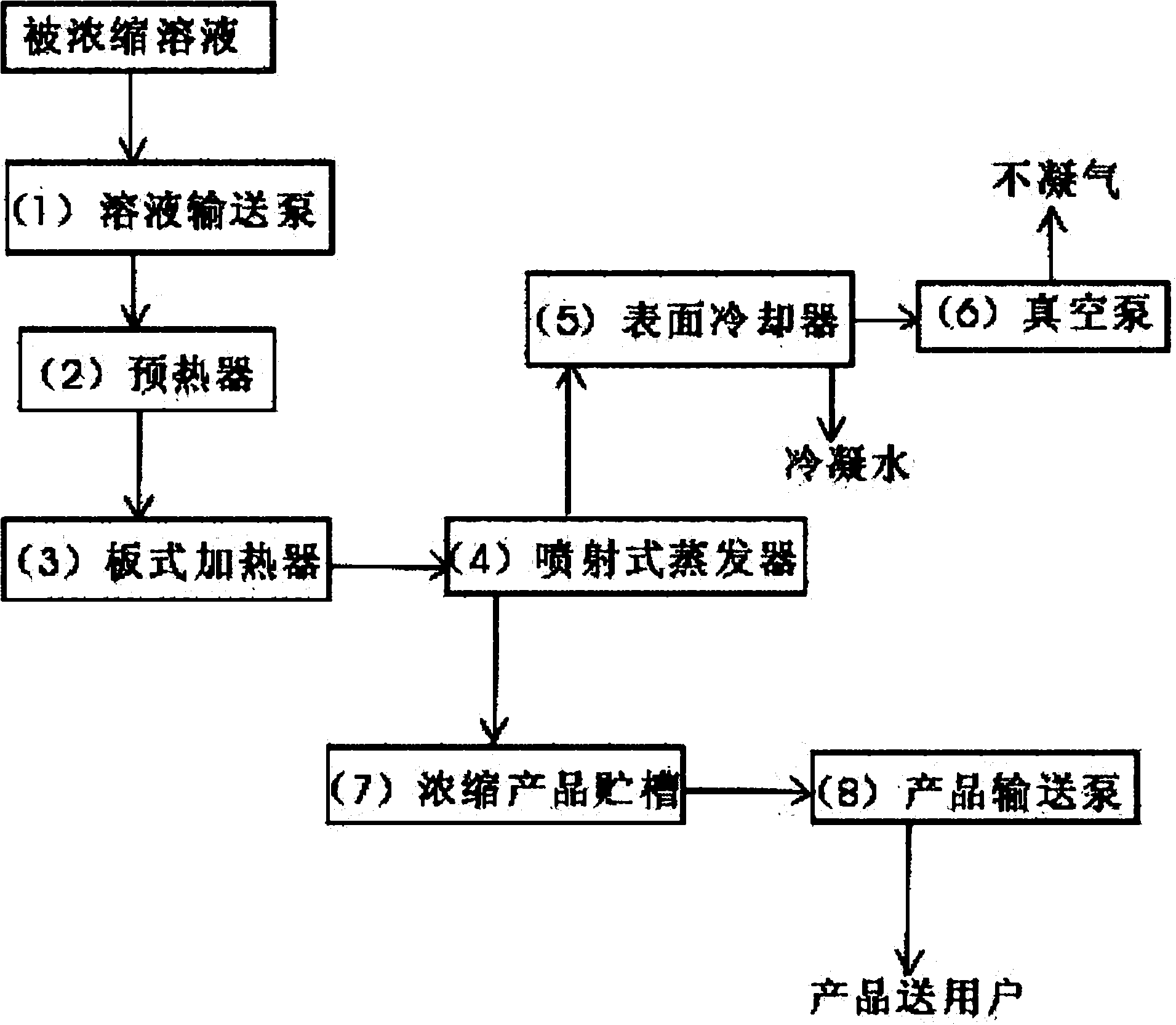

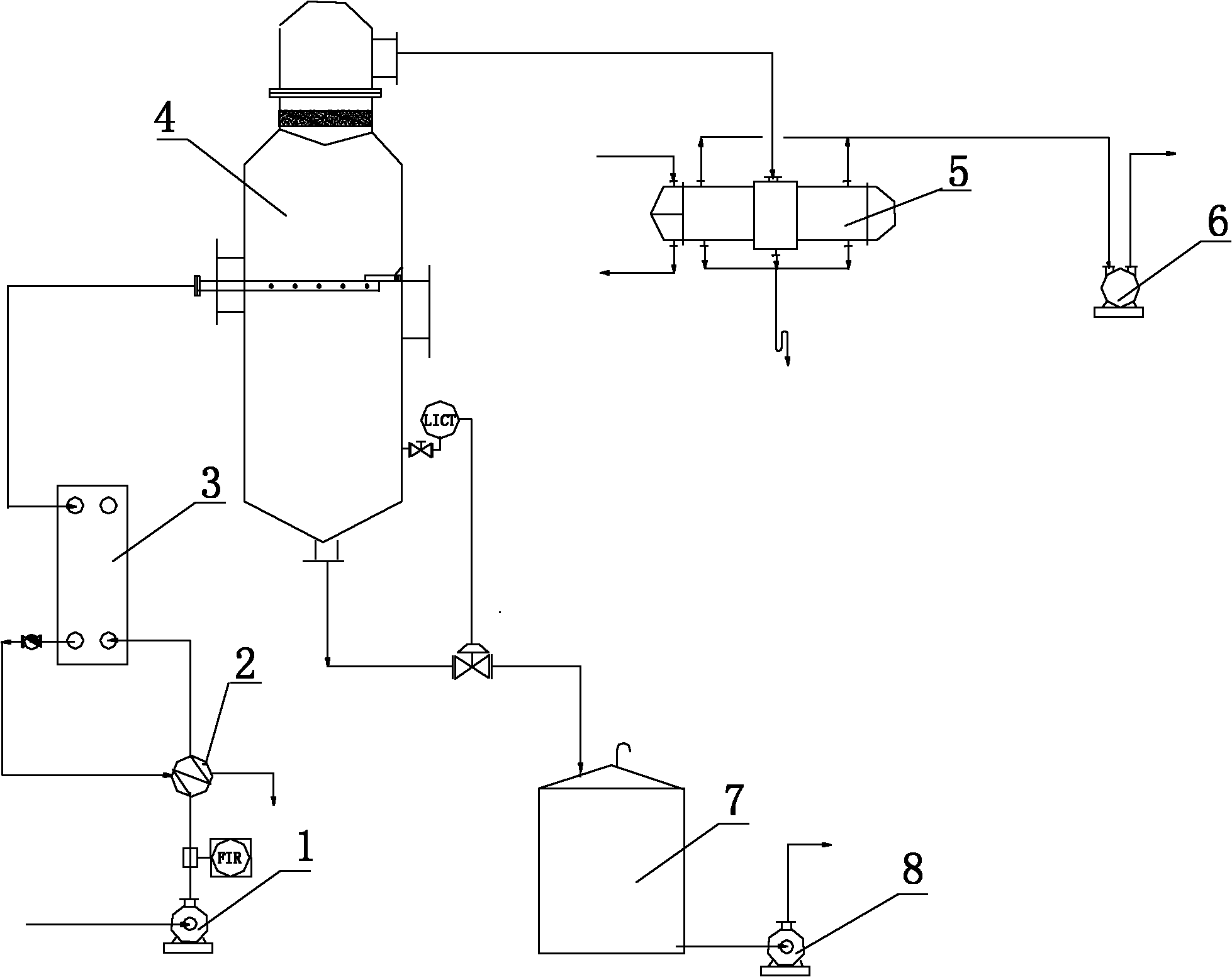

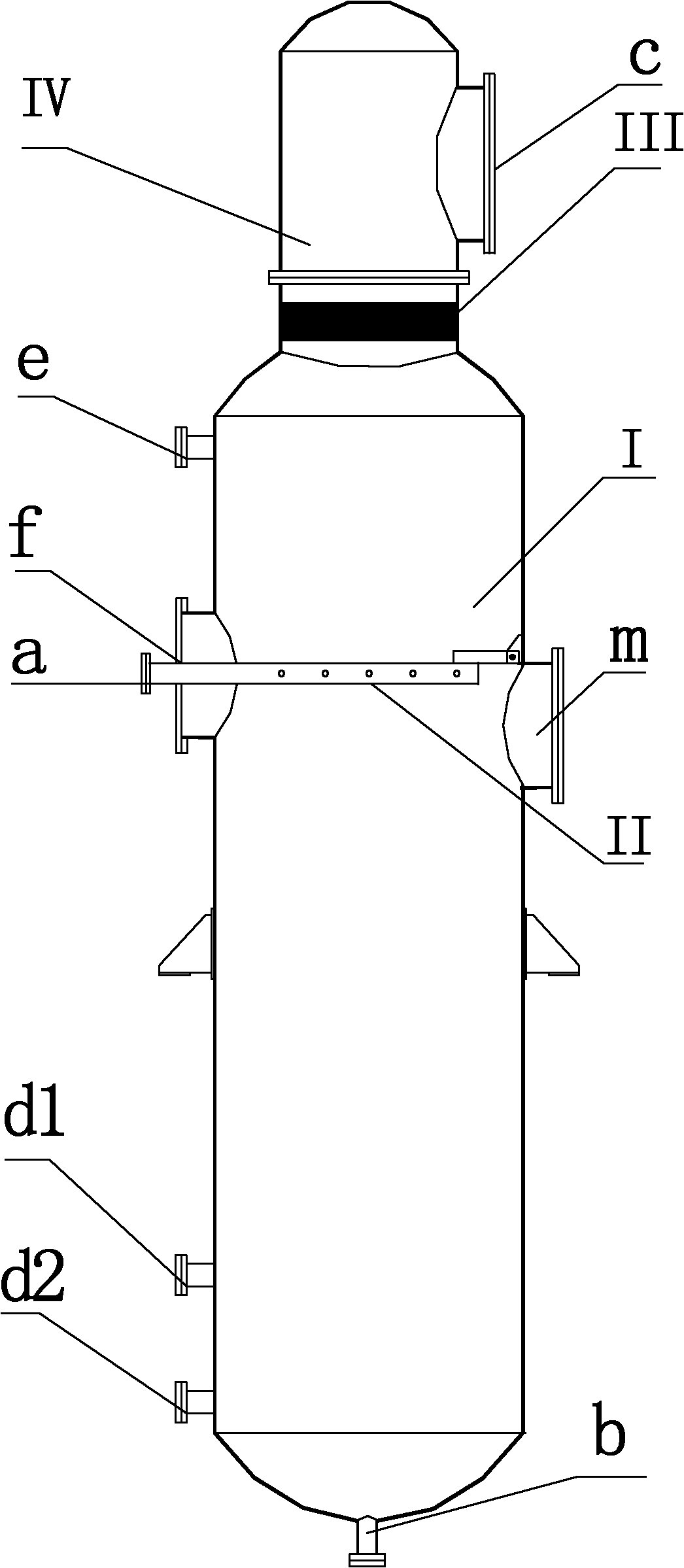

[0065] The following is attached figure 1 , figure 2 , image 3 , taking an annual output of 30kt / a mass fraction 48% potassium hydroxide concentration device, (mass fraction 30% potassium hydroxide solution is evaporated and concentrated to a mass fraction of 48%) using a single-effect jet injection solution evaporation concentration method and device as an example, the details Explain the application of the solution spray evaporation concentration method and device, so as to have a better understanding of the solution spray evaporation concentration method and the combined device.

[0066] An annual output of 30kt / a mass fraction 48% (the following description omits "mass fraction") potassium hydroxide single-effect spray injection solution evaporation concentration production device (see image 3 ).

[0067] Use a 48% potassium hydroxide concentration device with an annual output of 30kt / a to evaporate and concentrate 30% potassium hydroxide to 48%, and use a single-eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com