Device and method for disassembling plug-in mounted components of waste printed circuit board

A waste printed circuit and board plug-in technology, which is applied in the direction of electronic waste recycling, solid waste removal, recycling technology, etc., can solve the limitation of circuit board area size, can not achieve uniform grinding, pins are not easy to remove, etc. problems, to achieve the effect of improving the dismantling rate, facilitating separation and recycling, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

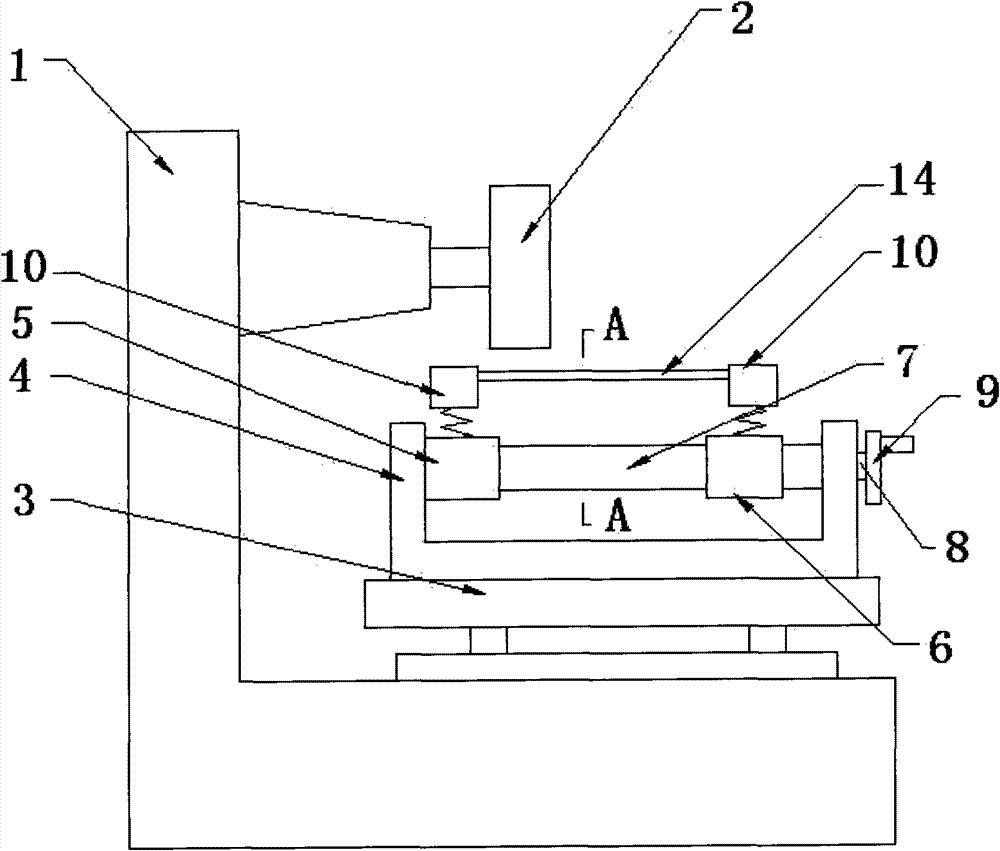

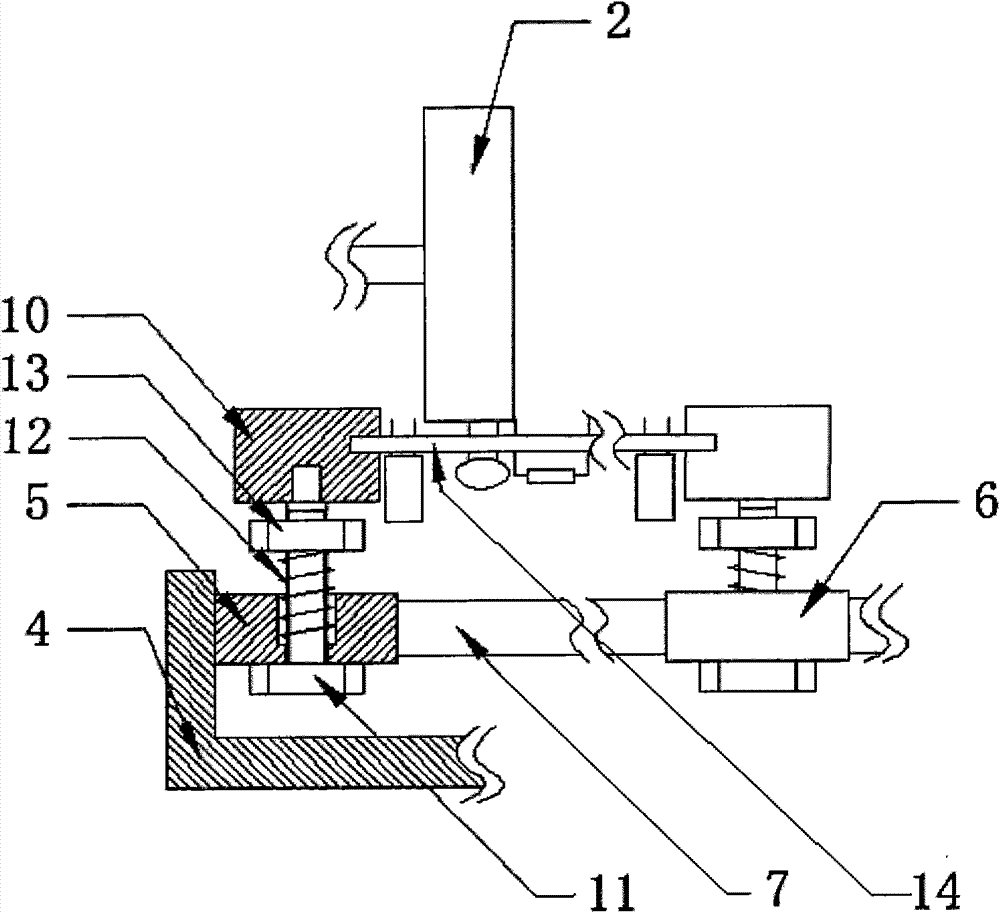

[0030] figure 1 It is a structural schematic diagram of an embodiment of the present invention. The waste printed circuit board plug-in component dismantling device is composed of a surface grinder 1, a fixture and a vacuum cleaner 15. The surface grinder 1 is a general surface grinder, and the fixture is fixed on the surface of the surface grinder 1. On the workbench 3 , the welding surface of the component pins of the circuit board 14 to be disassembled is clamped on the fixture, and the grinding wheel 2 of the surface grinder 1 is in contact with the component pins of the circuit board 14 for grinding. Cleaner 15 is fixed on the place ahead of emery wheel 2 rotation direction, as Figure 4 shown.

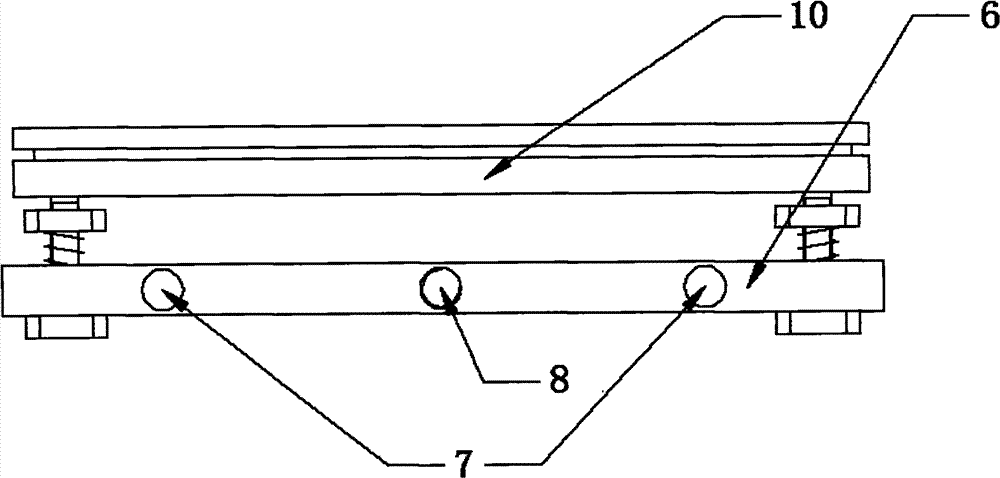

[0031]The components of the fixture include a fixture base 4, a fixed support beam 5, a movable support beam 6, a step screw 11, a spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com