Microwave pyrolysis-based decommissioned photovoltaic module efficient thermal stratification system and microwave pyrolysis-based decommissioned photovoltaic module efficient thermal stratification method

A photovoltaic module and thermal stratification technology, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc., can solve problems such as glass plates and battery sheets are easily broken, and achieve clean and efficient thermal stratification, high-efficiency thermal Layering, avoiding cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

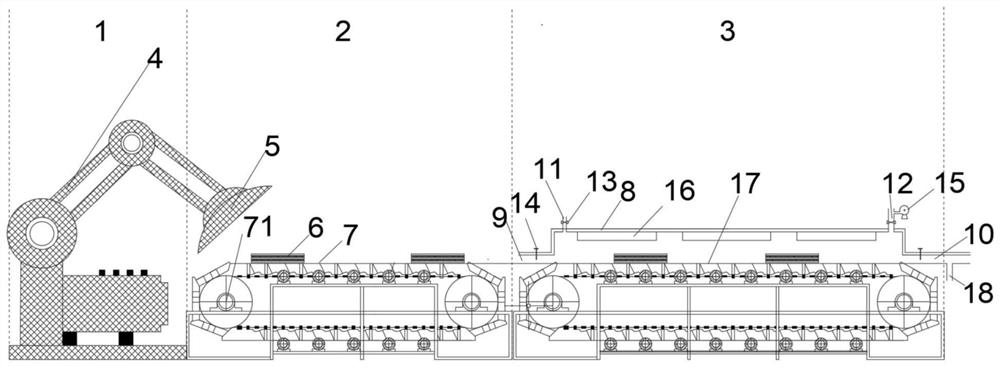

[0030] Such as figure 1 As shown, the crystalline silicon photovoltaic module with the junction box and aluminum frame disassembled is placed in the microwave pyrolysis furnace of this system, nitrogen gas is introduced into the furnace cavity, and three microwave generators are respectively set at 150°C and 350°C respectively. ℃ and 550 ℃, adjust the residence time of the core components in the furnace cavity to 30min, to obtain a complete glass plate and battery sheet, the yield of pyrolysis residue is about 10.56%.

[0031] At present, the commonly used physical crushing method needs to crush photovoltaic modules, and only metal and silicon wafer particles can be recovered, and complete glass plates and cells cannot be obtained, and the recovery rate is only about 70%.

Embodiment 2

[0033] Such as figure 1 As shown, the crystalline silicon photovoltaic module with the junction box and aluminum frame disassembled is placed in the microwave pyrolysis furnace of this system, nitrogen gas is introduced into the furnace cavity, and three microwave generators are respectively set at temperatures of 200 °C and 400 °C. ℃ and 600 ℃, adjust the residence time of the core components in the furnace cavity to 25min, to obtain a complete glass plate and battery sheet, the yield of pyrolysis residue is about 8.34%.

[0034] At present, the commonly used physical crushing method needs to crush photovoltaic modules, and only metal and silicon wafer particles can be recovered, and complete glass plates and cells cannot be obtained, and the recovery rate is only about 70%.

Embodiment 3

[0036] Such as figure 1 As shown, the crystalline silicon photovoltaic module with the junction box and aluminum frame disassembled is placed in the microwave pyrolysis furnace in this system, nitrogen gas is introduced into the furnace cavity, and three microwave generators are respectively set at a temperature of 100°C, At 300°C and 650°C, the residence time of the core components in the furnace chamber was adjusted to 20 minutes to obtain complete glass plates and battery sheets, and the yield of pyrolysis residue was about 7.02%.

[0037] At present, the commonly used physical crushing method needs to crush photovoltaic modules, and only metal and silicon wafer particles can be recovered, and complete glass plates and cells cannot be obtained, and the recovery rate is only about 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com