Hot air heating and vibratory force applying disassembly equipment for waste and used circuit boards

A waste circuit board and hot air heating technology, which is applied in metal processing equipment, welding equipment, electronic waste recycling, etc., can solve the problems of not being solved well at the same time, and achieve the effect of improving dismantling rate, improving efficiency, and reducing inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

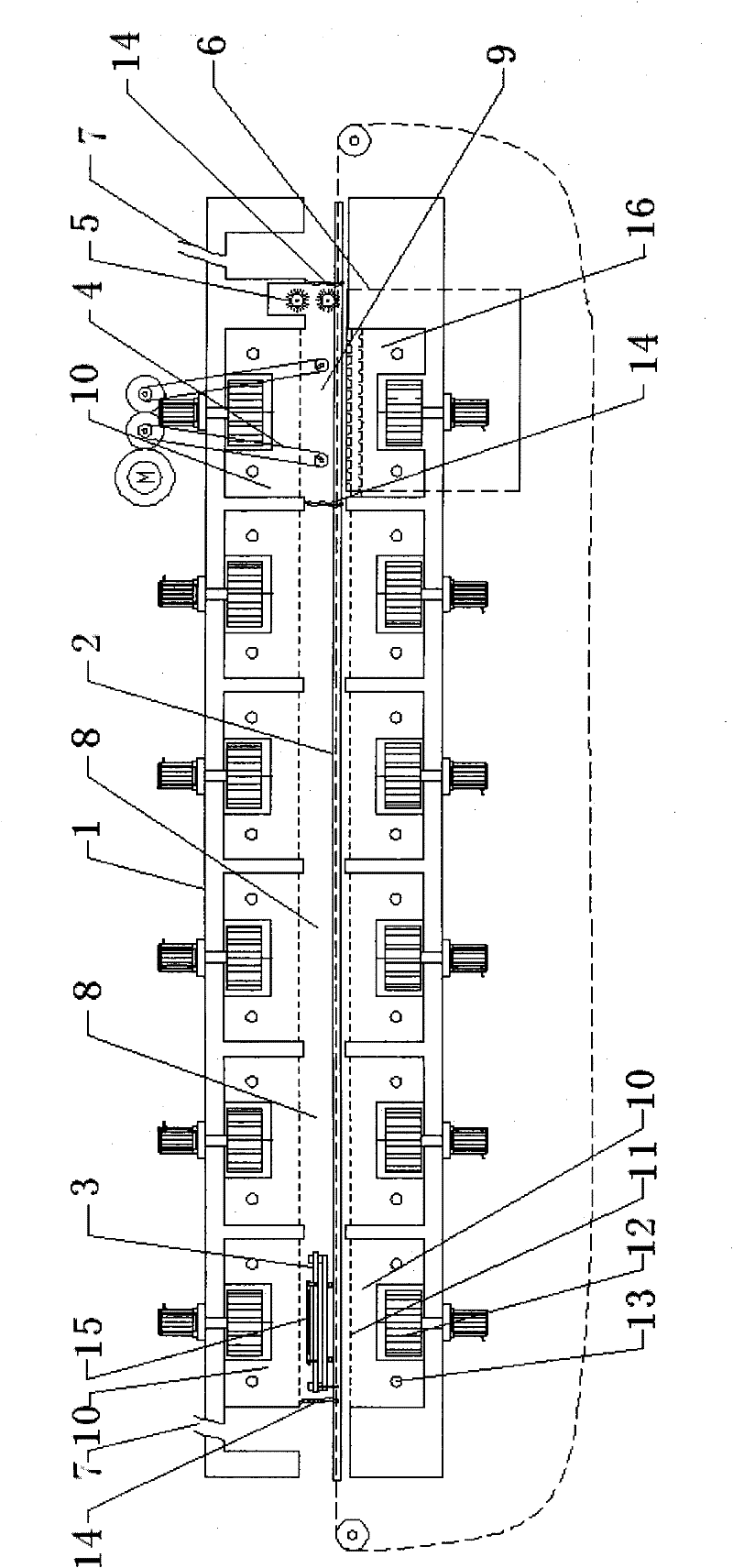

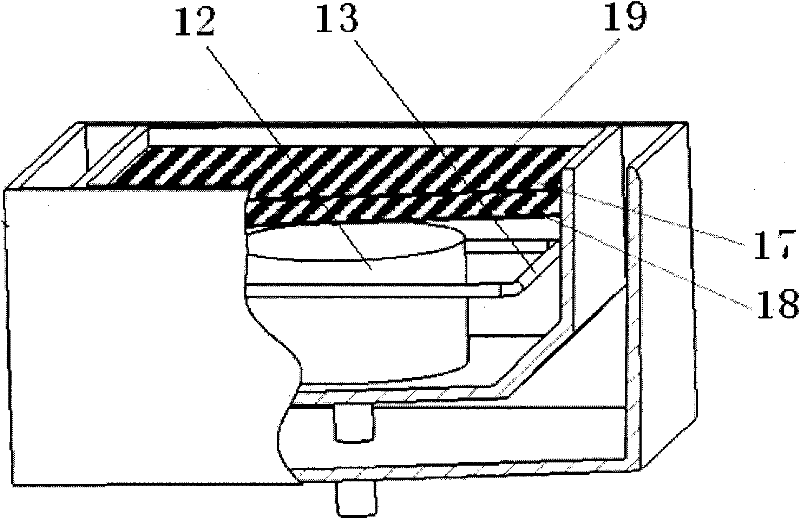

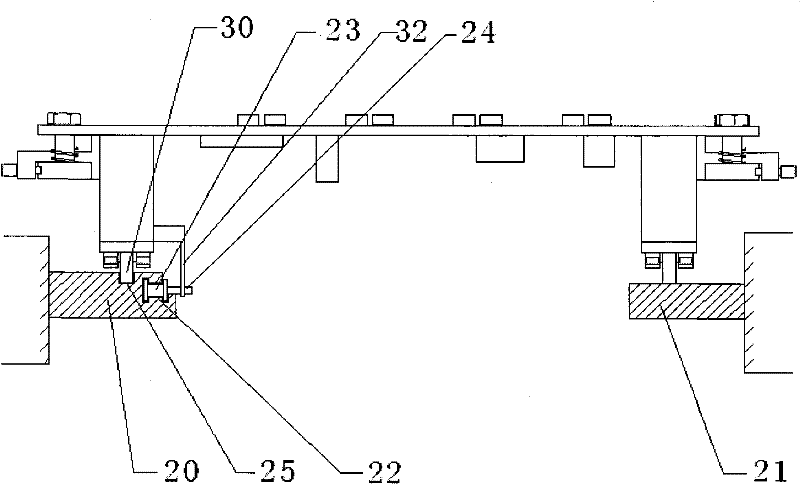

[0043] The dismantling equipment in this embodiment includes a hot air heating system 1, a transmission system 2, a fixture 3, an excitation mechanism 4, a sweeping mechanism 5, a component sending mesh belt 6, and an exhaust gas suction port 7. The overall structure diagram is as follows figure 1 shown. The hot air heating system 1 is composed of five low-temperature zones 8 and high-temperature zones 9 arranged vertically and horizontally, with the low-temperature zone 8 in front and the high-temperature zone 9 behind. The left guide rail 20, the right guide rail 21 and the chain 23 of the conveying system 2 pass through the low temperature zone 8 and the high temperature zone 9 of the hot air heating system 1, and the fixture 3 is placed on the left guide rail 20 and the right guide rail 21 and driven by the chain 23 from the low temperature zone 8 Transfer to high temperature zone 9. The vibration excitation mechanism 4 is placed above the conveying system 2 in the high t...

Embodiment 2

[0056] see Figure 7 , this embodiment provides another solution of the sweeping structure 5 . Its upper part still adopts the same structure as in Embodiment 1, but its lower part is a vertically rotating brush structure, and there are 2 to 10 vertical rotating shafts 56 perpendicular to the feeding direction of the circuit board, and each vertical rotating shaft 56 upper ends are fixed a disk 57, and vertical bristle 58 is arranged on the disk 57, and vertical bristle 58 is also steel wire bristle, and the lower end of each vertical rotating shaft 56 realizes the gear transmission connection with same horizontal transmission shaft 60 by bevel gear set 59 , the vertical bristles 58 sweep the lower surface of the circuit board 15 when the circuit board 15 passes by.

[0057] The invention is a device for vibrating and brushing to disassemble components from a printed circuit board without damage, and is used in recycling and reusing enterprises of waste products in the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com