SBS (styrene-butadiene-styrene) modified emulsified asphalt composition and preparation method thereof

A technology for emulsified asphalt and modified asphalt, applied in building structures, building components, building insulation materials, etc., can solve the problems of difficulty in obtaining emulsified SBS modified asphalt emulsion, poor emulsification effect, and difficulty in emulsification, and achieve storage stability. Excellent, low temperature ductility, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

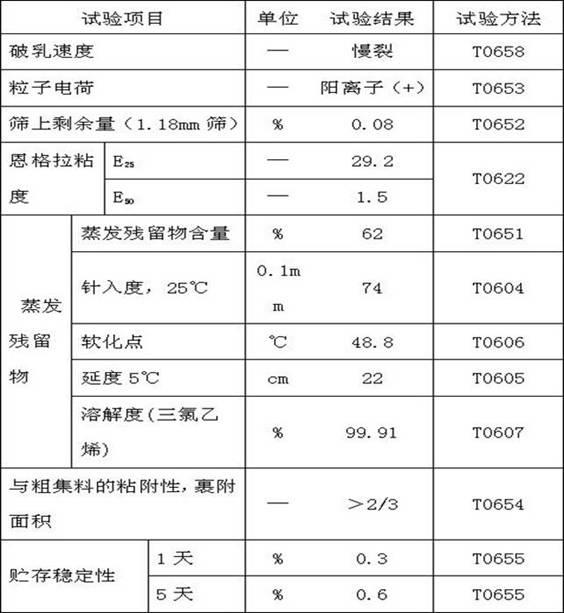

Image

Examples

Embodiment 1

[0026] A modified emulsified asphalt (SBS) composition, which is composed of base asphalt, SBS modifier, composite emulsifier, stabilizer, and hot water, and contains 35 to 65 parts of base asphalt by mass ratio, and 1 to 4 parts of SBS modifier, 0.3 to 3 parts of composite emulsifier, 0.05 to 0.5 part of stabilizer, 30 to 60 parts of hot water at 50°C to 70°C, wherein the base asphalt is road petroleum asphalt, and the The SBS modifier is a solid high molecular polymer thermoplastic rubber, and the composite emulsifier is a mixture of an amine cationic emulsifier and a non-ionic fluorocarbon emulsifier, and the compounding mass ratio of the compound is amine cationic emulsifier : Nonionic fluorocarbon emulsifier=90~99:1~10, the composite emulsifier also contains 0.1 part~0.25 part hydrochloric acid.

[0027] A kind of preparation method of modified emulsified asphalt, carries out according to the following steps successively:

[0028] 1) Preparation of modified asphalt (SBS)...

Embodiment 2

[0035] The material composition of SBS modified emulsified asphalt of the present invention is:

[0036] Base asphalt 60 parts

[0037] SBS modifier 1.5 parts

[0038] Compound emulsifier 1.5 parts

[0039] 36 parts of hot water at 50℃~70℃

[0040] Stabilizer 0.16 parts

[0041] Hydrochloric acid 0.2 parts

[0042] The preparation method of SBS modified emulsified asphalt of the present invention is:

[0043] Step 1: Prepare SBS modified asphalt

[0044] Heat 60 parts of base asphalt until melted, raise the temperature to 170°C~185°C, add 1.5 parts of SBS, stir at constant temperature for 10~30min to swell, after the swelling is completed, shear or grind until the SBS particles are ≤5 microns, shear or Continue to stir for 2 hours after grinding to prepare SBS modified asphalt for later use.

[0045] The second step: prepare emulsifier aqueous solution

[0046] Add 1.5 parts of compound emulsifier, 0.16 parts of formulated stabilizer and 0.2 parts of hydrochloric acid ...

Embodiment 3

[0052] The material composition of SBS modified emulsified asphalt of the present invention is:

[0053] Base asphalt 52 parts

[0054] SBS modifier 1.6 parts

[0055] Compound emulsifier 1.0 parts

[0056] 45 parts of hot water at 50℃~70℃

[0057] Stabilizer 0.2 parts

[0058]Hydrochloric acid 0.2 parts

[0059] The preparation method of SBS modified emulsified asphalt of the present invention is:

[0060] Step 1: Prepare SBS modified asphalt

[0061] Heat 52 parts of base asphalt until melted, raise the temperature to 170°C~185°C, add 1.6 parts of SBS, stir at constant temperature for 10~30min to swell, after the swelling is completed, shear or grind until the SBS particles are ≤5 microns, shear or Continue to stir for 2 hours after grinding to prepare SBS modified asphalt for later use.

[0062] The second step: prepare emulsifier aqueous solution

[0063] Add 1 part of compound emulsifier, 0.2 part of formulated stabilizer and 0.2 part of hydrochloric acid to 45 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com