Oil/electric integrated power wheel-type workover rig

A technology of power wheels and workover rigs, which is applied in drilling equipment, drilling equipment and methods, earth-moving drilling and mining, etc., can solve the problem that the wheeled workover rig has not reached the scrapping cycle, high purchase cost, and the possibility of one-time elimination is not possible. Large and other problems, to achieve the effect of compact design structure, short transmission path and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

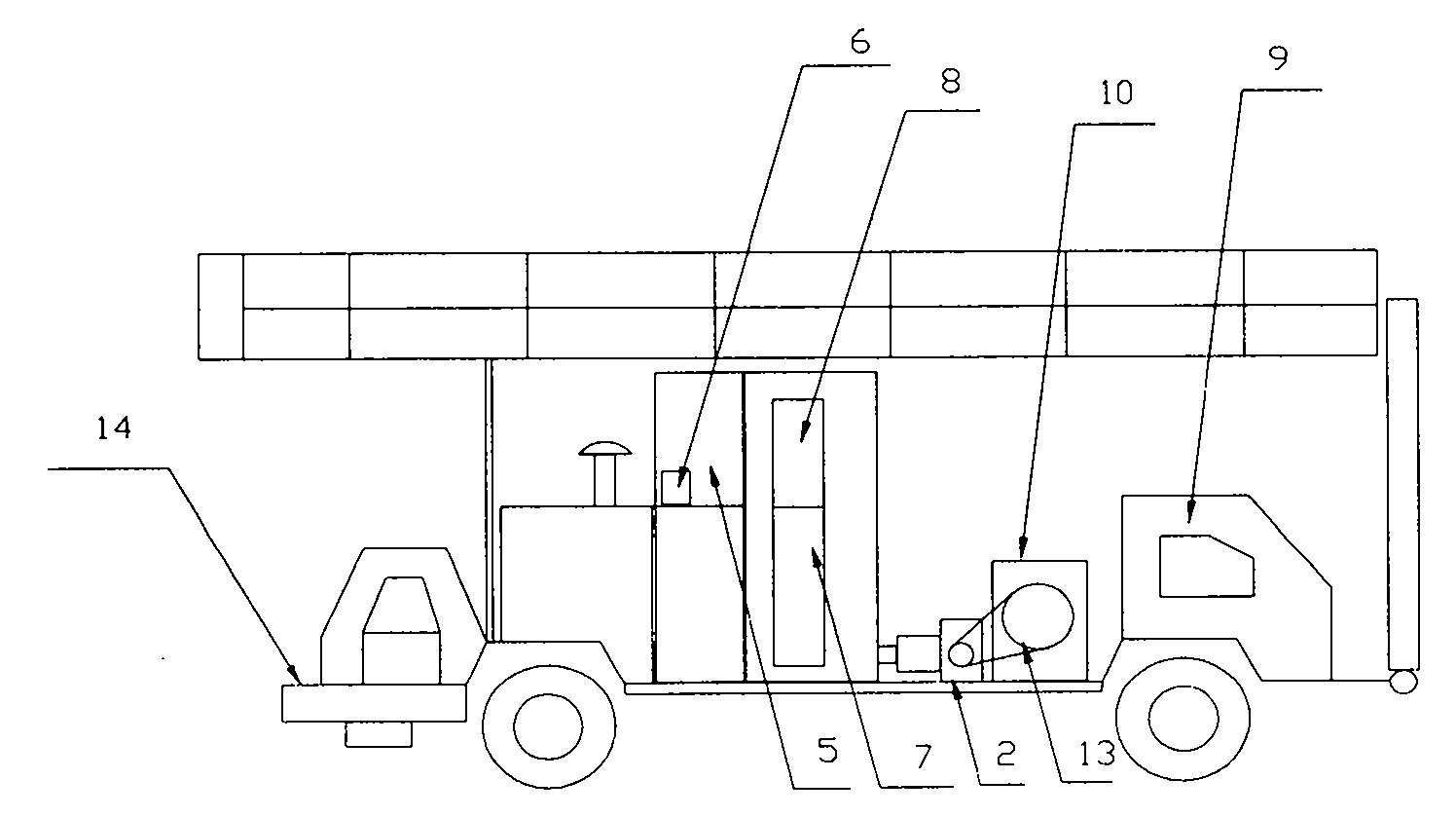

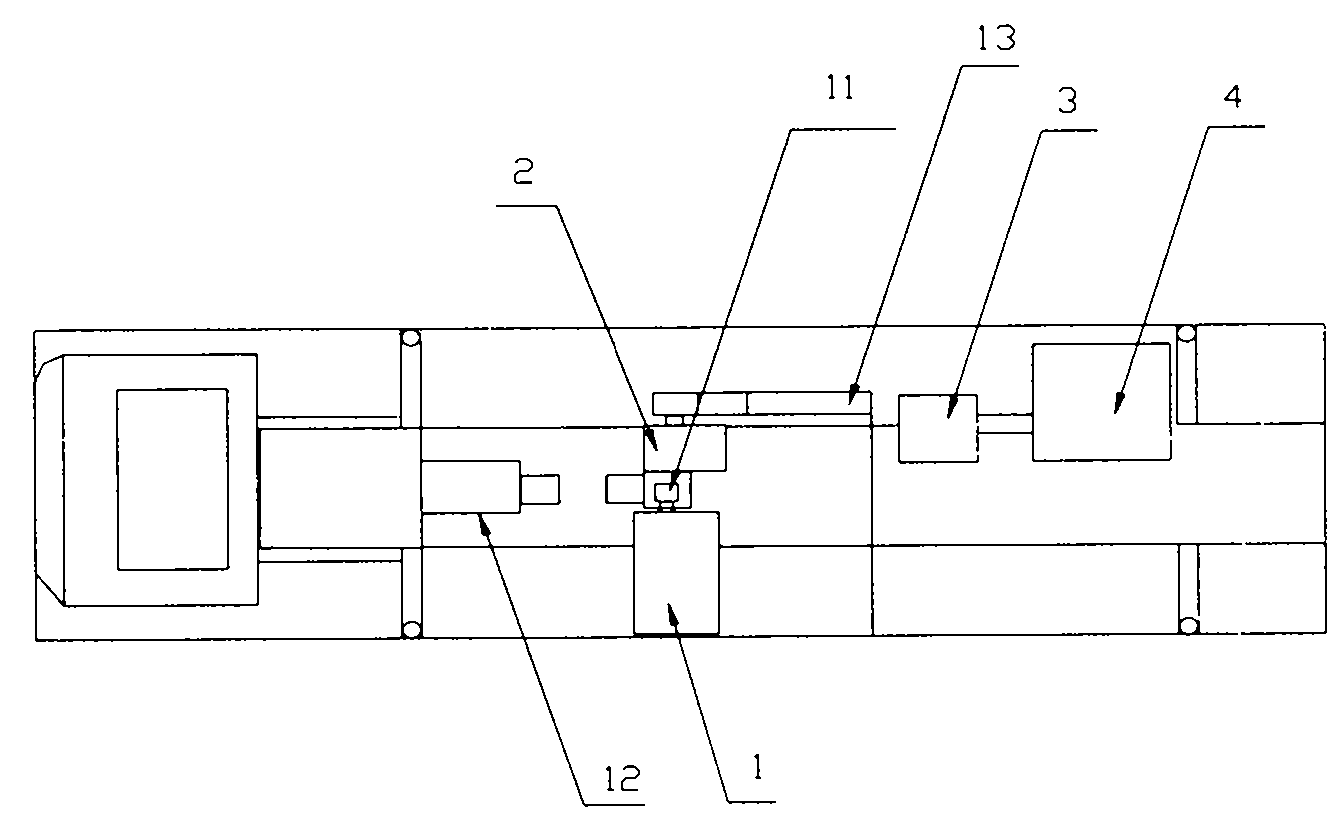

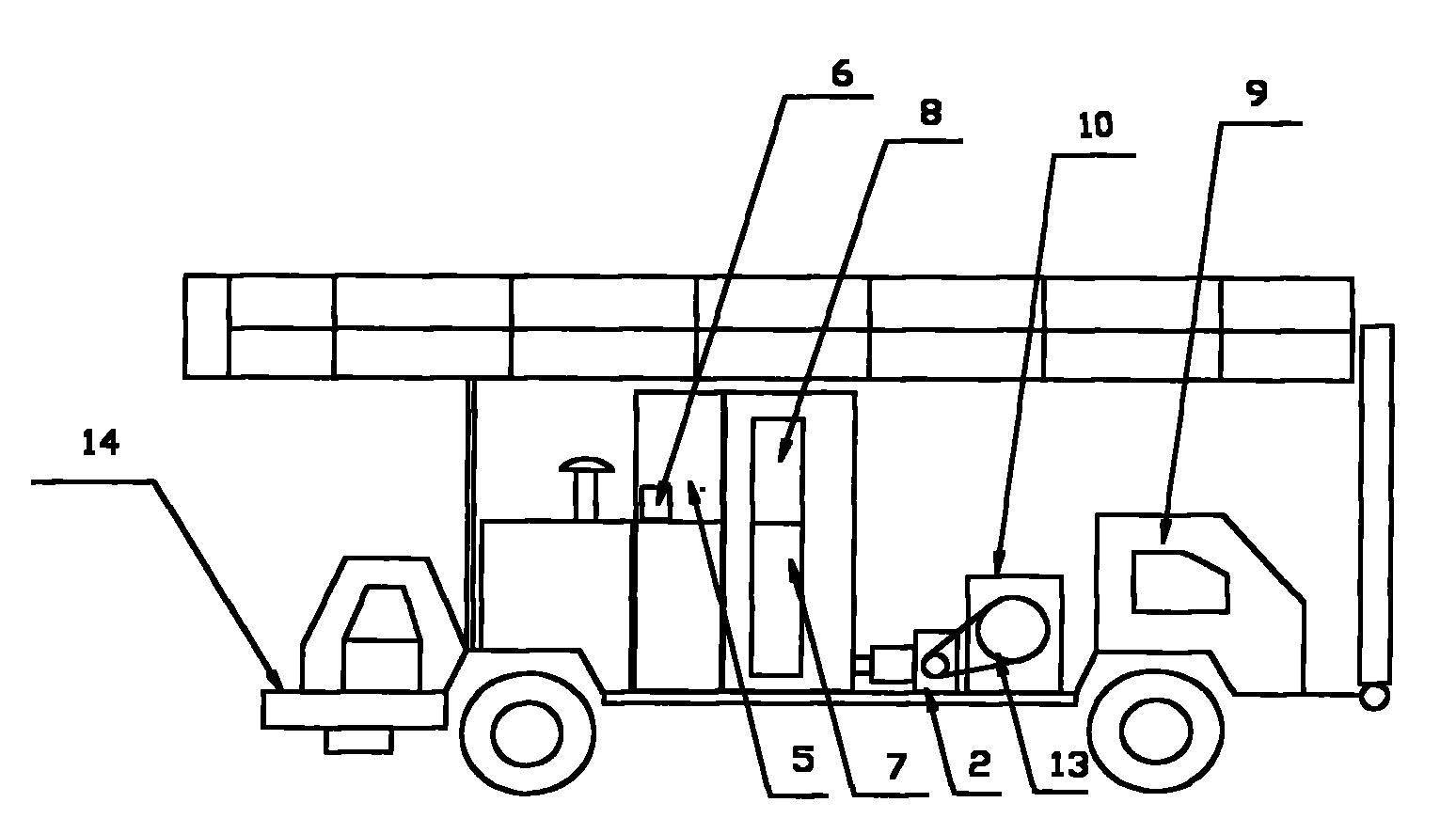

[0026] As shown in the figure, the oil / electric comprehensive power wheeled workover rig includes a diesel engine 12 placed on a car body 14, a hydraulic torque converter, an automatic transmission, a transmission shaft, a winch drum, and is equipped with a car body 14. The frequency conversion power drive system on the above; the frequency conversion power drive system includes a frequency conversion motor 1, a dual power hybrid commutator 2, a shaft coupling 11, an oil pump motor 3, a hydraulic pump 4 and a power supply; the output shaft of the frequency conversion motor 1 is connected to the The coupling 11 of the dual-power hybrid converter 2 is fixedly connected; the output power of the dual-power hybrid converter 2 is transmitted to the winch through the sprocket 13; the output shaft of the oil pump motor 3 is fixed to the input shaft of the hydraulic pump 4 Matching; the power supply provides electric energy for the variable frequency motor 1 and the vehicle body 14. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com