Method and device for detecting slag boundary viscosity temperature of Shell gasification furnace

A critical viscosity and slag technology, applied in the field of detecting the critical viscosity temperature of Shell coal gasifier slag, can solve the problems of lag, inability to meet the requirements of industrial online measurement of critical viscosity temperature of slag, troublesome operation, etc., to achieve sensitive response, simple and convenient measurement, Easy and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

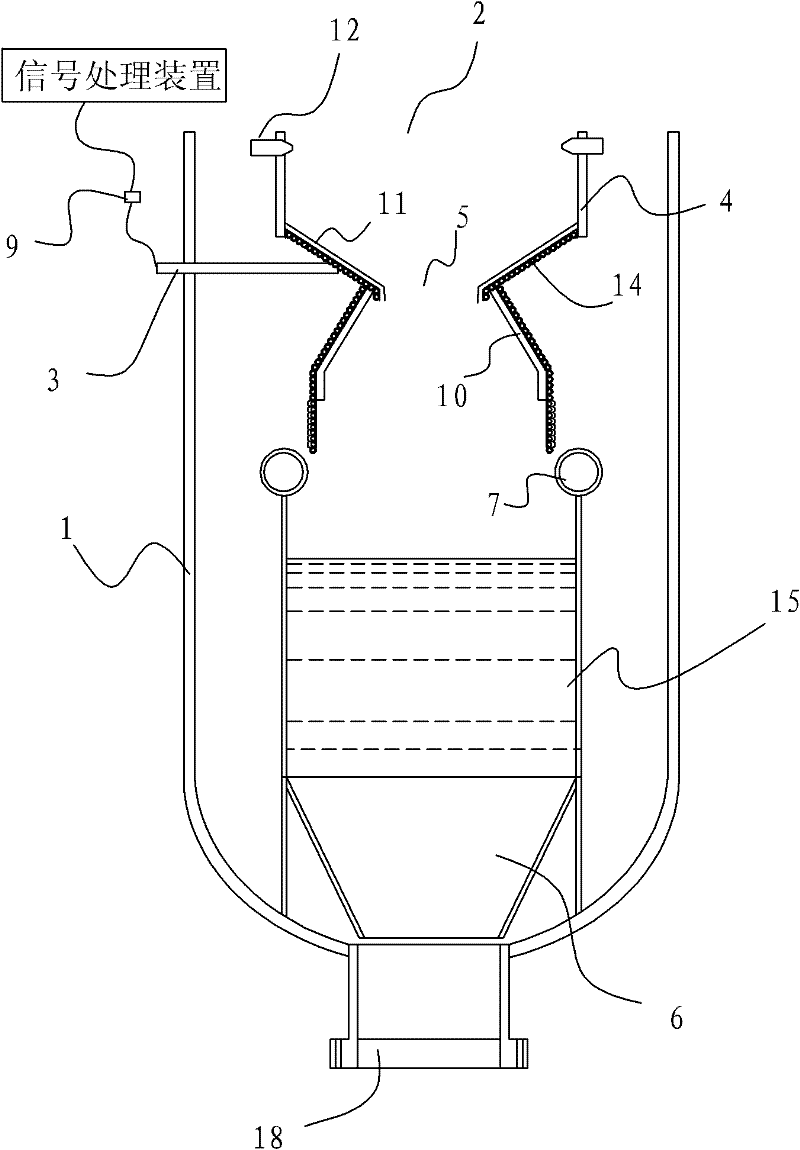

[0019] Such as figure 1 Shown, a Shell coal gasifier, the main structure of the device is the same as the fuel gasification device disclosed in Chinese patent 200580039681.1, it includes a pressure shell 1, the shape of the pressure shell 1 is roughly elliptical in longitudinal section, and its internal air pressure is 7 to 70 bar, with a discharge port 18 at the bottom for discharging slag and water.

[0020] The pressure shell 1 is provided with a gasification chamber 2 surrounded by a gasifier wall 4. The gasifier wall 4 is a membrane wall structure for circulating cooling fluid. The membrane wall structure is composed of a plurality of horizontally arranged annular tubes . A burner (not shown) is arranged above the gasification chamber 2, and four nozzles 12 are arranged inside it, and the nozzles 12 mainly deliver raw materials to the gasification chamber, and the raw materials mainly include water vapor, oxygen and coal powder.

[0021] The bottom of the gasifier wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com