Spin valve structure with electric field-adjustable magnetoresistance and preparation process thereof

A technology of electric field adjustment and preparation process, applied in the field of magnetic storage, which can solve the problems that can only be observed at lower temperatures, low impedance value, large leakage conductance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

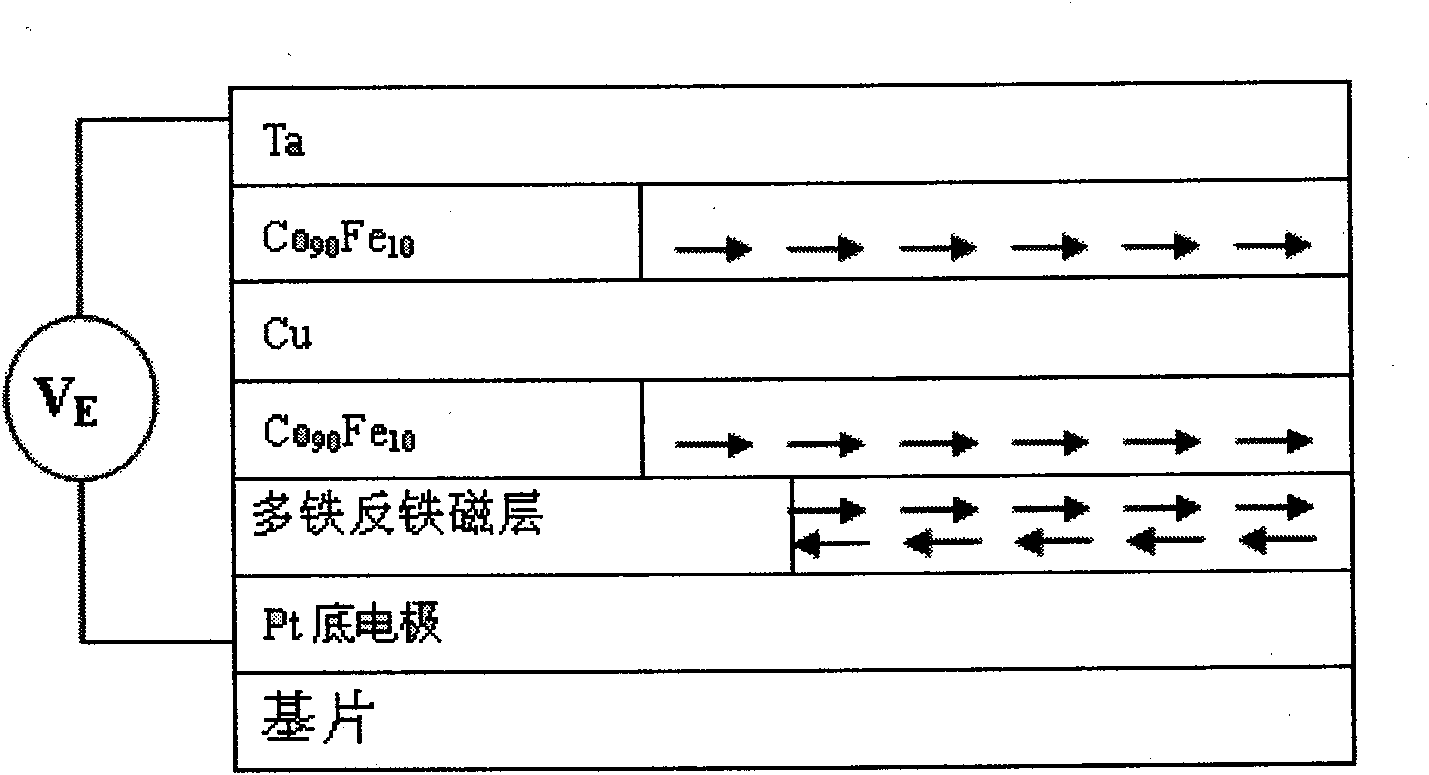

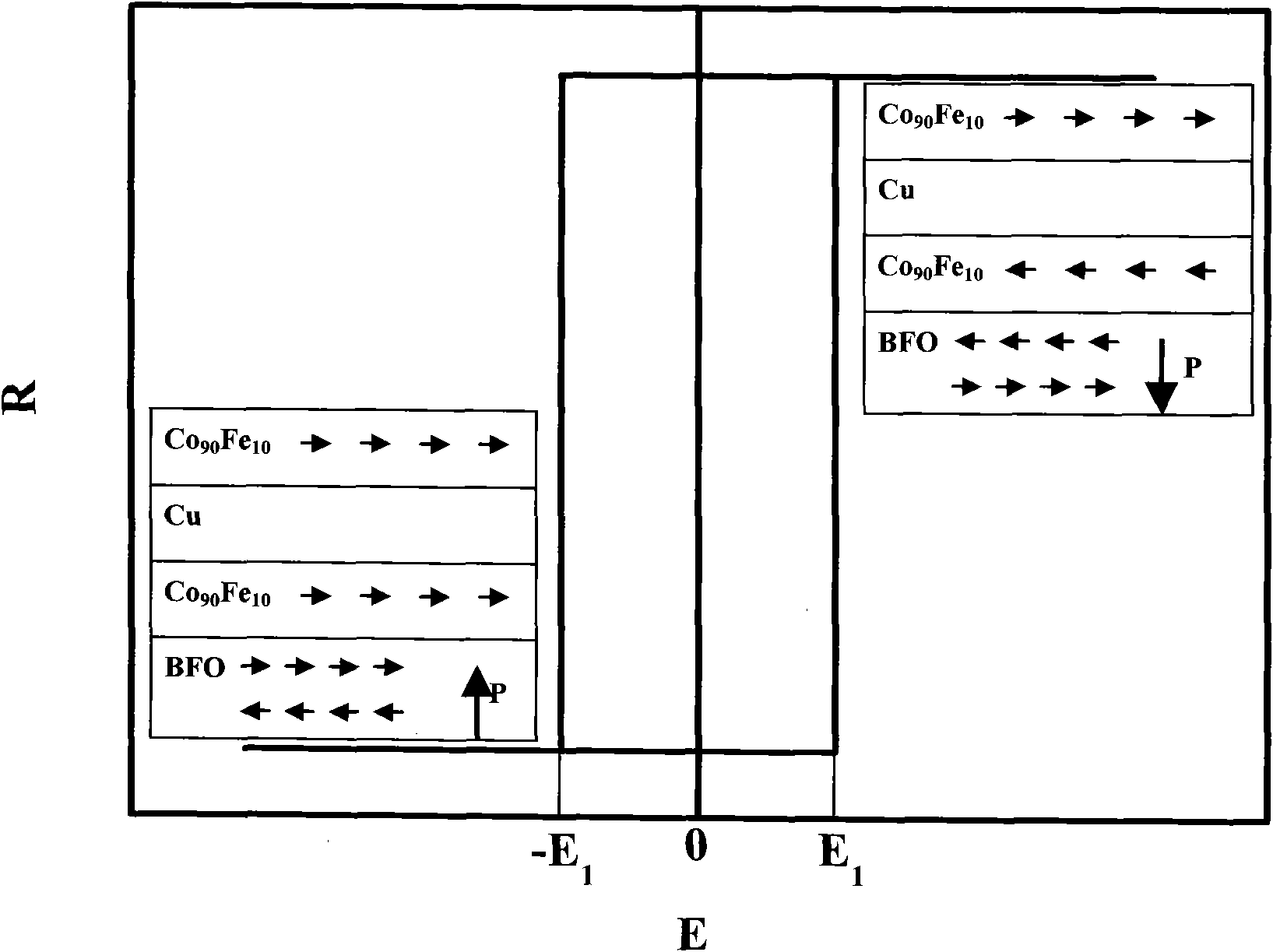

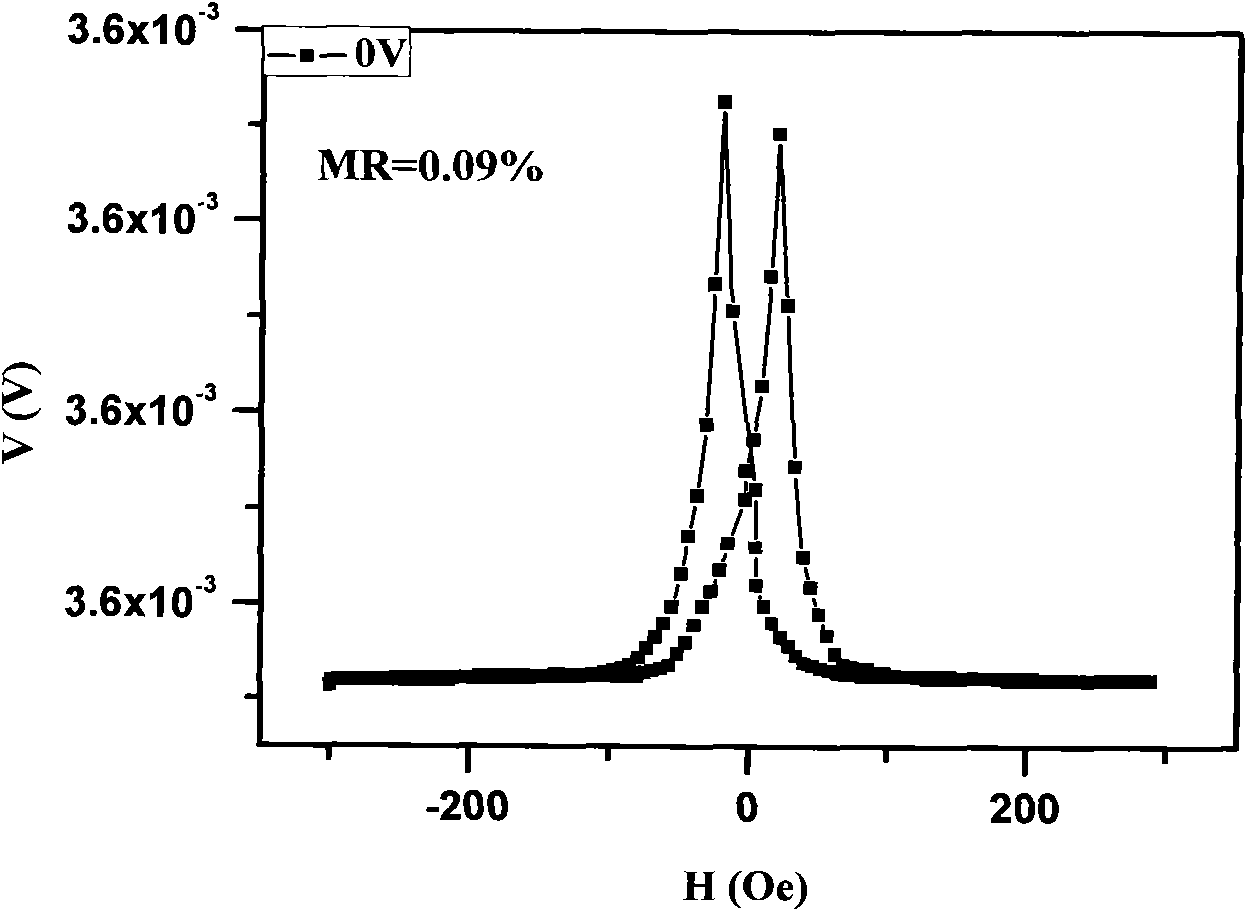

[0029] According to the above structure, the applicant has grown a new spin valve structure by using laser pulse deposition and magnetron sputtering system respectively:

[0030] Sample 1: Multiferroic material BiFeO 3 The antiferromagnetic layer is deposited on the substrate by laser pulse deposition, and then the spin valve is grown in situ by magnetron sputtering. The detailed preparation process of the above structure is: using Pt(111) / Ti / SiO 2 / Si substrate, Pt layer as the bottom electrode, the size is 10*10(mm 2); laser pulse deposition and growth of multiferroic antiferromagnetic layer, laser energy is 300mJ, frequency is 5Hz, oxygen (99.99%) pressure is 0.8~10Pa during deposition, temperature is 650~750℃, annealing oxygen pressure is 20~300Pa , the annealing time is 30 minutes; the spin valve structure is grown by magnetron sputtering, and the background vacuum degree of the sputtering chamber is 2×10 -5 Pa, the pressure of argon (99.99%) during sputtering is 0.5 P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com