Test structure and test method for coupling capacitance of metal redundant fillers in integrated circuit

A technology for testing structure and coupling capacitance, which is applied in circuits, semiconductor/solid-state device testing/measurement, electrical components, etc. It can solve the problems of error between simulation results and actual values, time-consuming simulation calculation, complex circuit model, etc., and achieve simplification. Measuring the effect of the question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and a specific embodiment.

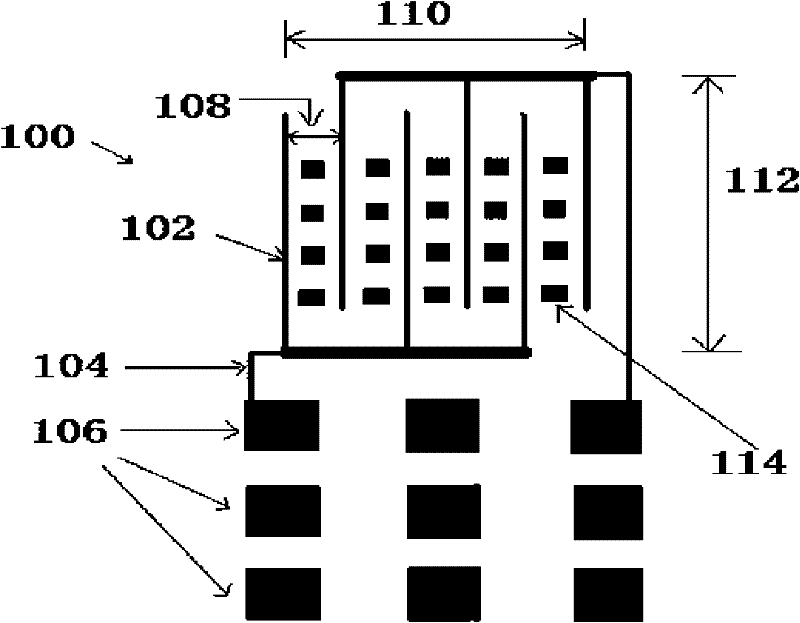

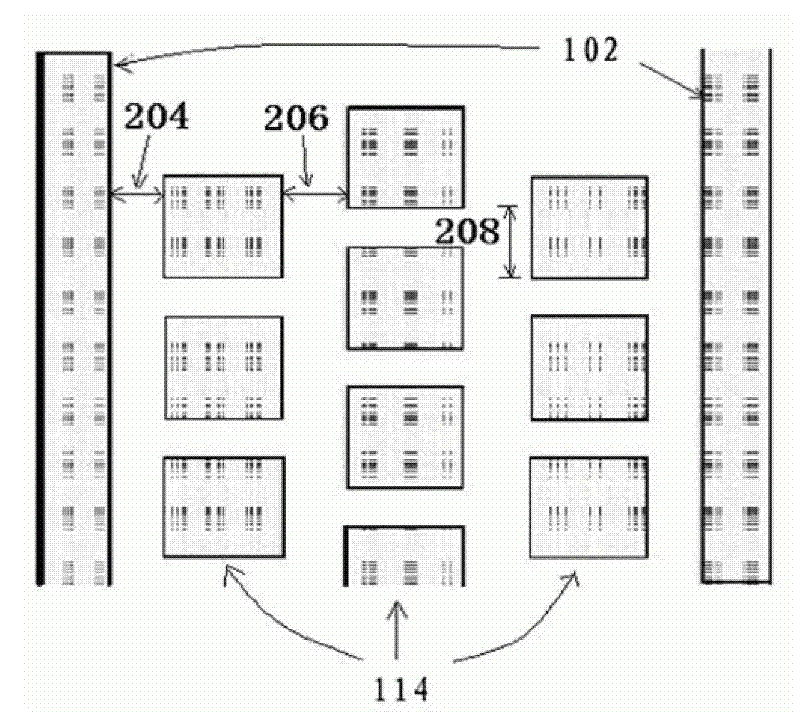

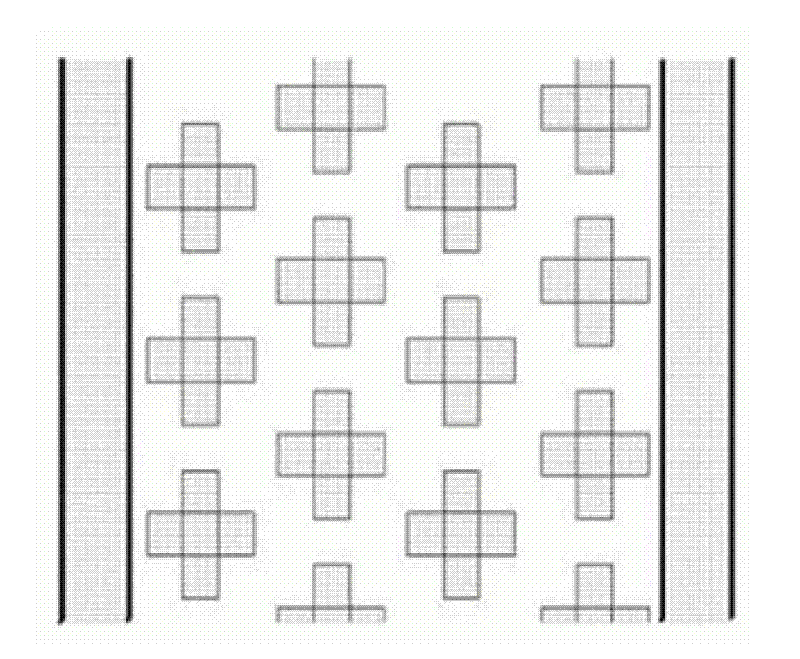

[0041] see figure 1 The invention provides a test structure for the coupling capacitance of an integrated circuit metal redundant filling, which is used for measuring the coupling capacitance of the integrated circuit structure. The test structure of this embodiment is a multi-layer structure composed of several test metal layers, figure 1 is a schematic diagram of a single-layer test metal layer. The test metal layer is set on the medium 100, and its main body is a square copper wire array to be tested, and the array is formed by arranging a plurality of copper wires to be tested 102 parallel to each other, as shown in the figure, odd-numbered columns in the array ( figure 1 The copper wires 102 to be tested in columns 1, 3, and 5) are connected by horizontal leads inside the array to form a comb-shaped copper wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com