Tuning-fork vibrator and method for manufacturing the same and angular speed sensor

A manufacturing method and oscillator technology, applied in the direction of speed measurement, speed/acceleration/shock measurement, instruments, etc. by gyro effect, can solve the problems of reduced foot electrode area, reduced oscillator sensitivity, and reduced insulation reliability. Achieve the effect of improving the S/N ratio, improving the output efficiency, and increasing the electrode area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

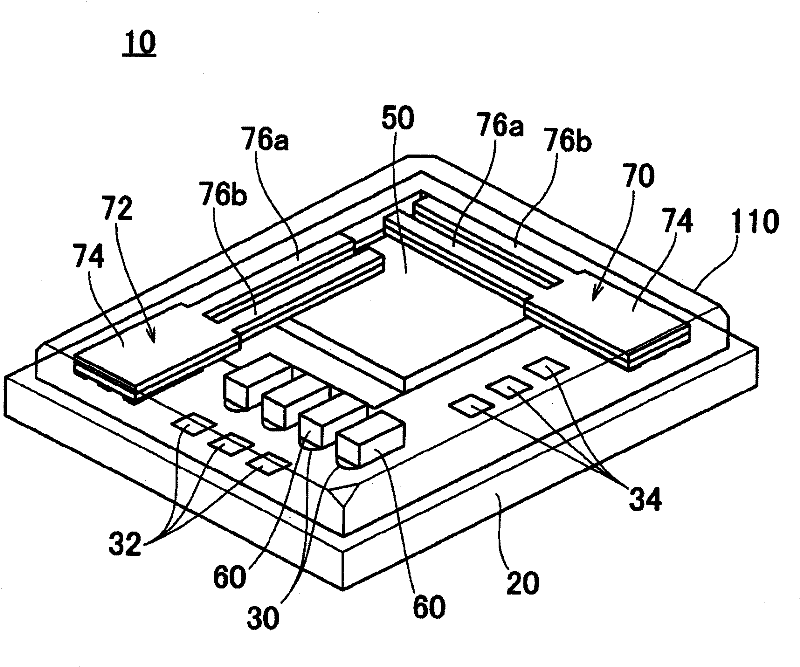

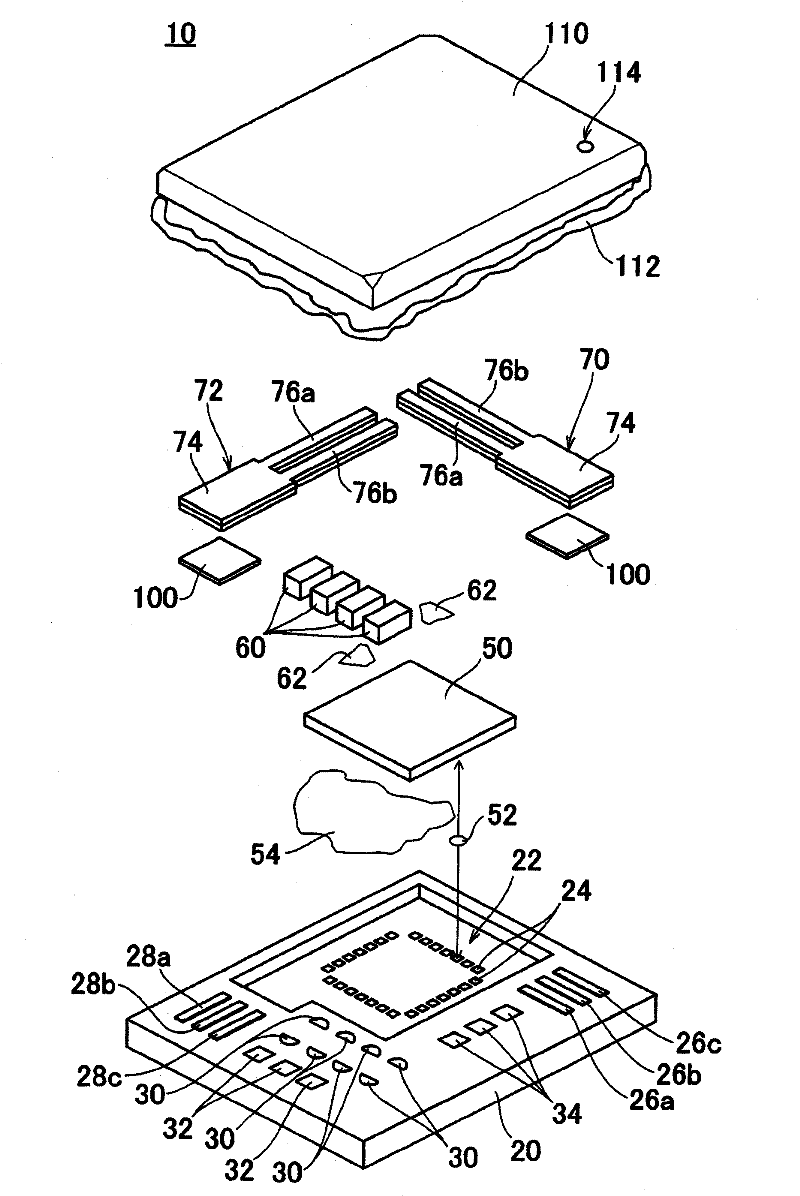

[0032] figure 1 It is an internal transparent perspective view showing an example of an angular velocity sensor using the tuning fork oscillator of the present invention, figure 2 is its exploded perspective view. The angular velocity sensor 10 includes a circuit board 20 . The circuit board 20 is formed in a shape such as a rectangular plate shape, for example. A concave portion 22 is formed on one surface of the circuit board 20 . The concave portion 22 is formed, for example, at a position close to one corner of the circuit board 20 . in addition, figure 2 Here, the concave portion 22 is formed in a hook shape, but any shape can be used as long as an IC described later can be mounted, for example, a square shape or the like may be used.

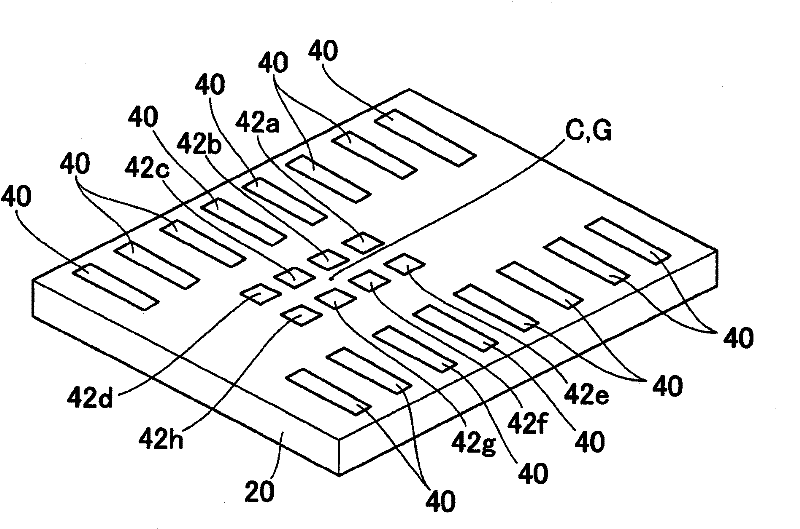

[0033] In the concave portion 22 of the circuit board 20 , a plurality of electrodes 24 are formed side by side in a quadrangular shape, for example. Further, outside the recess 22 of the circuit board 20 , three rectangular elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com