Liquid dairy product added with rice bran polypeptides and preparation method thereof

A technology for rice bran polypeptides and dairy products, applied in dairy products, milk preparations, applications, etc., can solve the problems of easy precipitation and damage to the stability of dairy products, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

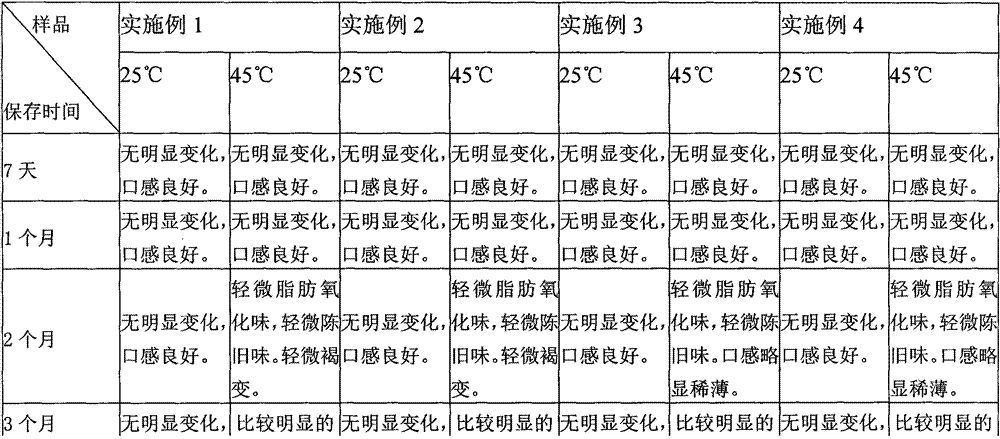

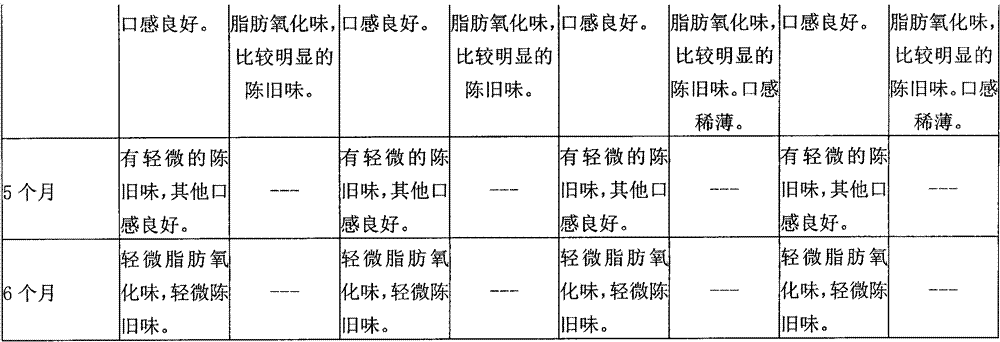

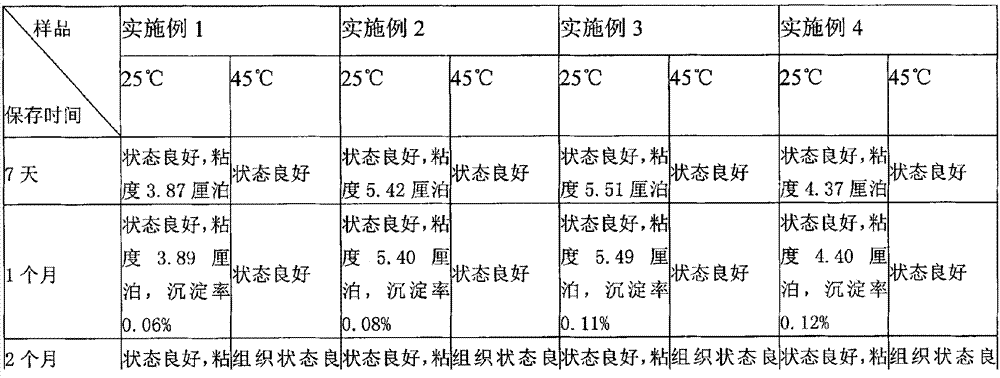

Examples

Embodiment 1

[0068] Embodiment 1, seasoned milk containing rice bran polypeptide and production method thereof

[0069] The proportioning of each raw material is based on the gross weight of this flavored milk in the present embodiment:

[0070] Milk 996.20‰, carrageenan 0.05‰, sucrose ester 0.20‰, glyceryl monostearate 2.5‰, glyceryl distearate 0.30‰, xanthan gum 0.05‰, guar gum 0.05‰, rice bran polypeptide (Japanese rich Erma Co., Ltd.) 0.13‰, sodium tripolyphosphate 0.20‰, disodium hydrogen phosphate 0.10‰, sodium hexametaphosphate 0.10‰, food flavor 0.12‰.

[0071] The specific production method of flavored milk in the present embodiment is as follows:

[0072] (1) Whole milk, partially skimmed milk or skimmed milk that meets the requirements of the present invention is obtained by standardizing the fresh milk through concentration and fat separation, and reconstituted milk can also be used.

[0073] (2) Use 25% to 35% of the total milk in the formula and heat it indirectly to 60°C t...

Embodiment 2

[0082] Embodiment 2, seasoned milk containing rice bran polypeptide and production method thereof

[0083] The proportioning of each raw material is based on the gross weight of this flavored milk in the present embodiment:

[0084] Milk 800.00‰, Carrageenan 0.15‰, Guar Gum 0.10‰, Sucrose Ester 0.15‰, Glyceryl Distearate 0.30‰, Glyceryl Monostearate 0.10‰, Microcrystalline Cellulose 2.60‰, White Sugar 20.00‰ , fructose syrup 10.00‰, rice bran polypeptide (Japan Fuerma Co., Ltd.) 0.20‰, disodium hydrogen phosphate 0.20‰, sodium tripolyphosphate 0.30‰, sucralose 0.10‰, acesulfame potassium 0.15‰, cyclamate 0.20% , food flavor 0.42‰, water to make up the balance.

[0085] The specific production method of flavored milk in the present embodiment is as follows:

[0086] (1) Whole milk, partially skimmed milk or skimmed milk that meets the requirements of the present invention is obtained by standardizing the fresh milk through concentration and fat separation, and reconstituted m...

Embodiment 3

[0096] Embodiment 3, milk drink containing rice bran polypeptide and production method thereof

[0097] In the present embodiment, the ratio of each raw material is based on the total weight of the milk drink:

[0098] Milk 300.00‰, Carrageenan 0.16‰, Guar Gum 0.10‰, Sucrose Ester 0.12‰, Glyceryl Distearate 0.20‰, Glyceryl Monostearate 0.10‰, Microcrystalline Cellulose 3.00‰, Xanthan Gum 0.10 ‰, White Sugar 10.00‰, Fructose Syrup 20.00‰, Rice Bran Peptide (Japan Fuerma Co., Ltd.) 0.20‰, Disodium Hydrogen Phosphate 0.10‰, Sodium Tripolyphosphate 0.20‰, Sodium Hexametaphosphate 0.12‰, Neotame 0.004 ‰, acesulfame potassium 0.15‰, cyclamate 0.40%, food flavor 0.50‰, water to make up the balance.

[0099] The concrete production method of milk beverage in the present embodiment is as follows:

[0100] (1) Whole milk, partially skimmed milk or skimmed milk that meets the requirements of the present invention is obtained by standardizing the fresh milk through concentration and fat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com