Preparation method of organic silicon methoxy/ethoxy high boiling silicone oil

A high-boiling silicone oil and organosilicon technology, which is applied in the preparation field of organosilicon methyl ethoxy high-boiling silicone oil, can solve the problems of complex process, high product cost, many three wastes, etc., and achieves process rationalization, high operation flexibility, and reduced production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for preparing organosilicon methyl ethoxy high-boiling silicone oil, taking 100 parts (mass parts, the same below) of organosilicon high-boiling mixture with a boiling range of 80-215°C, and putting them into a reactor with condensing reflux at one time , start stirring and add dropwise 95 parts of 97wt% CH at room temperature 3 OH: In the first stage, control the temperature ≤ 35°C, add dropwise for 1h; in the second stage, control the temperature ≤ 45°C, add dropwise for 0.5h; in the third stage, control the temperature ≤ 55°C, add dropwise for 0.5h; in the fourth stage, control the temperature ≤ 60 ℃, add dropwise for 1h; CH 3 After the dropwise addition of OH, control the temperature to ≤60°C to continue the reaction for 2 hours, and the reaction ends. Cool to room temperature and stand to separate layers. After separation, the upper layer is a brownish-yellow methoxylated acidic high boiler, and the lower layer is a methoxylated raffinate. The HCl tail g...

Embodiment 2-3

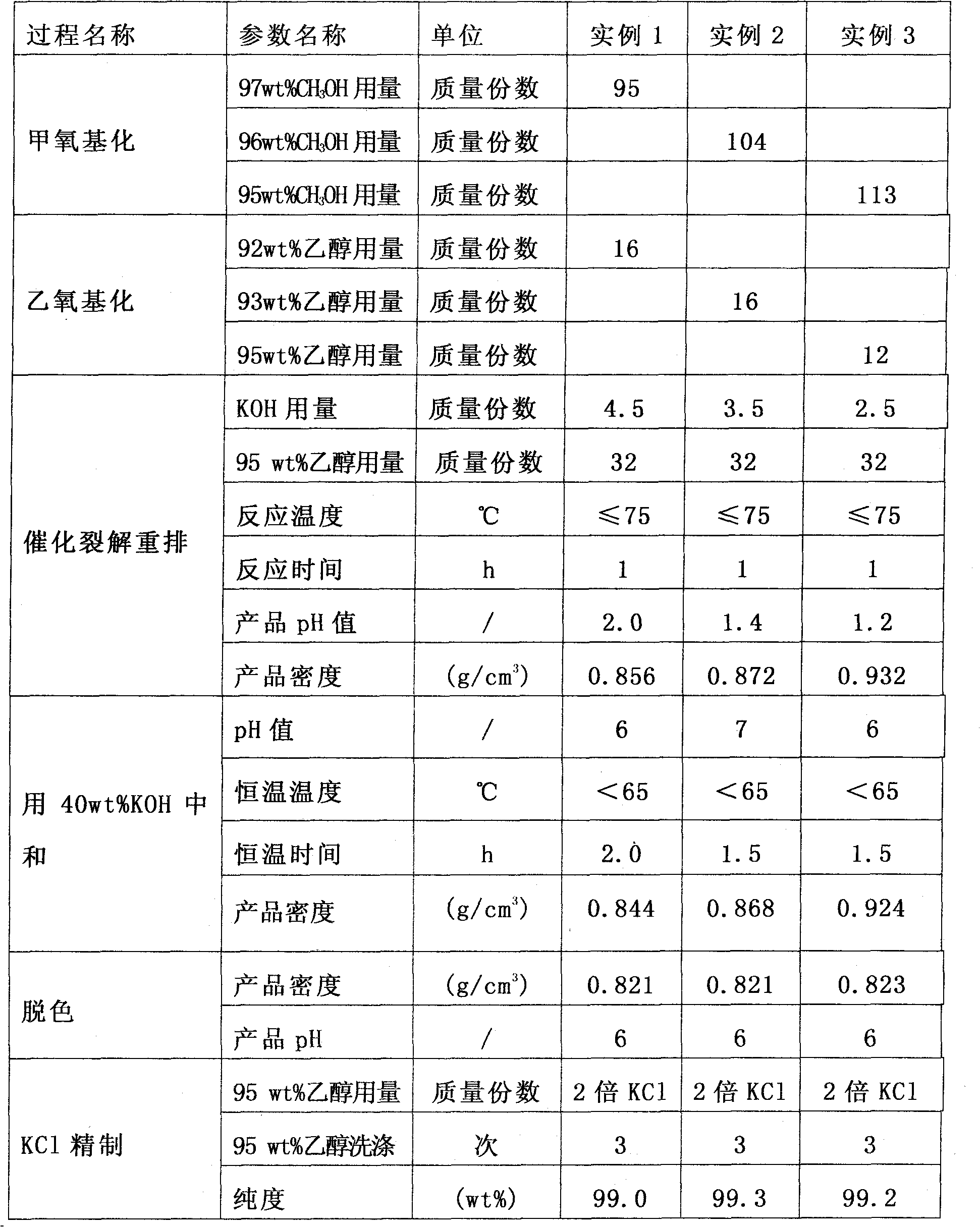

[0024] Operation steps are as embodiment 1, and its technological parameters are shown in Table 1

[0025] Table 1. Embodiment 1-3 process parameter table

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com