Yoghourt flavor chocolate composition for coating frozen beverage

A technology for frozen drinks and compositions, applied in the fields of application, frozen desserts, food science, etc., can solve the problems of lack of taste, inconspicuous taste, unfavorable consumer recognition, etc., and achieve rich yogurt flavor, rich new taste, enhanced The effect of shape retention and melting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

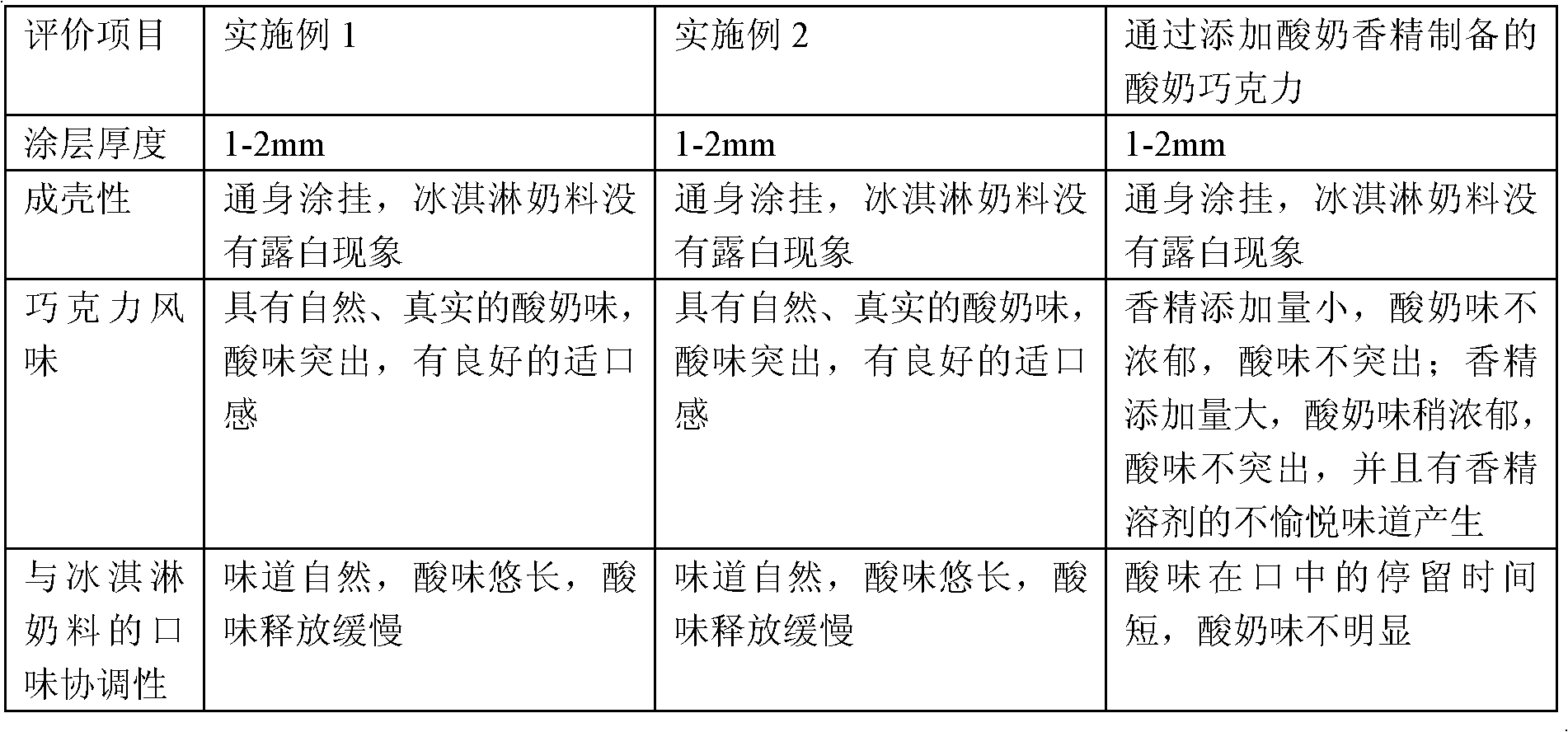

Examples

Embodiment 1

[0028] The yoghurt-flavored chocolate composition formula in the present embodiment is:

[0029] 220 parts by weight of white sugar; 180 parts by weight of whole milk powder; 280 parts by weight of coconut oil; 230 parts by weight of palm oil; 50 parts by weight of maltodextrin; 30 parts by weight of cocoa butter substitute; 1 part by weight of lecithin; 1.5 parts by weight of alcohol ester; 3.5 parts by weight of citric acid; 4 parts by weight of emulsifier of sucrose fatty acid ester (HLB value 3); 0.0003 parts by weight of butter essence.

[0030] When utilizing the composition of the present embodiment to coat and hang frozen drinks, it mainly operates according to the following methods:

[0031] Prepare chocolate slurry for coating: Weigh various raw materials according to the formula and weighing requirements; heat and melt palm oil, coconut oil, and cocoa butter substitute; Add oil to the fine grinder from the feeding port of the main engine, and then add the powdered ...

Embodiment 2

[0035] The yoghurt-flavored chocolate composition formula in the present embodiment is:

[0036] 180 parts by weight of white sugar; 190 parts by weight of whole milk powder; 380 parts by weight of coconut oil; 140 parts by weight of palm oil; 80 parts by weight of maltodextrin; 20 parts by weight of cocoa butter substitute; 0.8 parts by weight of lecithin; 2 parts by weight of alcohol ester; 3 parts by weight of malic acid; 4 parts by weight of glyceryl monostearate (HLB value 3.6-4.2); 0.0002 parts by weight of cream flavor.

[0037] When utilizing the composition of the present embodiment to coat and hang frozen drinks, it mainly operates according to the following methods:

[0038] Prepare chocolate slurry for coating: Weigh various raw materials according to the formula and weighing requirements; heat and melt palm oil, coconut oil, and cocoa butter substitute; Add oil to the fine grinder from the feeding port of the main engine, and then add the powdered raw milk powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com