L-tryptophan gene engineering bacterium, method for constructing same and method for fermenting and producing L-tryptophan by using same

A tryptophan and gene technology, applied in the field of high-yield L-tryptophan genetically engineered strains, can solve problems such as complex regulatory mechanism, weak metabolic flow, and long biosynthetic pathway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

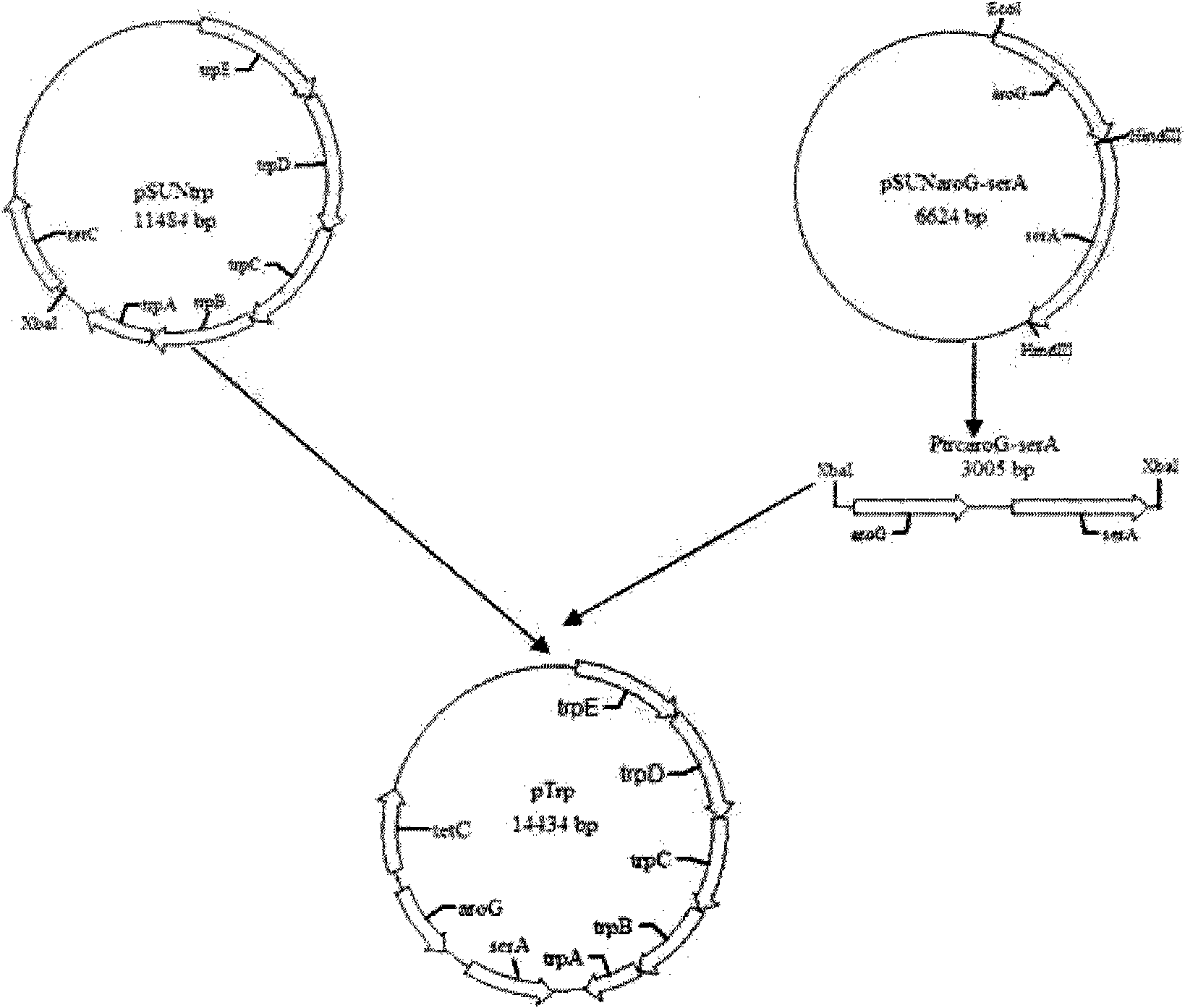

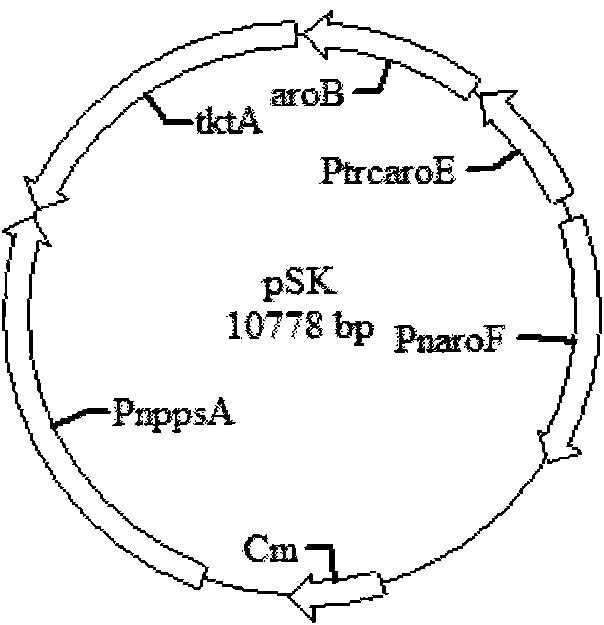

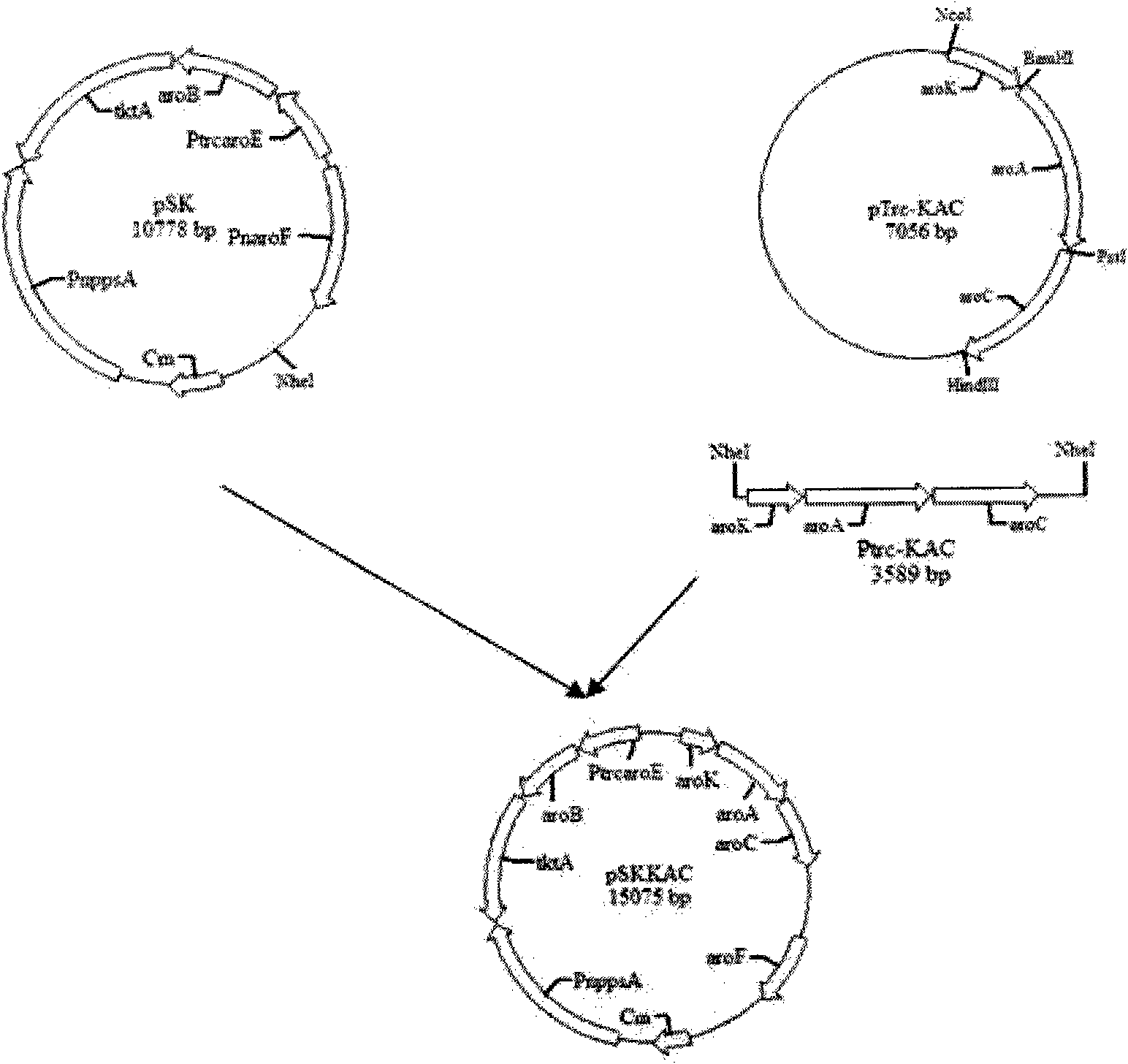

Method used

Image

Examples

Embodiment 1

[0044] Example 1 : Preparation of strain CGSC7692 (ΔpheA) with knockout pheA gene

[0045] 1. Preparation of mutant strain CGSC7692 (ΔpheA::Kan)

[0046] Using the CGSC10048 (ΔpheA::Kan) genome as a template, primers pheA-V-F and pheA-V-R were used to amplify the pheA mutant gene fragment by PCR. The primer sequences are as follows:

[0047] Forward primer pheA-V-F: 5'-GGAGGCGTTTCGTCGTGTGA-3' (SEQ ID NO: 1)

[0048] Reverse primer pheA-V-R: 5'-GCAAGGTGGAGCACTGGTTC-3' (SEQ ID NO: 2)

[0049] Amplification reaction system: 10×KOD buffer (without MgSO 4 )5μl, MgSO 4 (25mM) 3μl, dNTP (2.5mM) 4μl, KOD polymerase 1μl, template 1μl, forward primer (10μM) 2μl, reverse primer (10μM) 2μl, add ddH O to 50μl (the PCR reaction reagents used in the present invention are all purchased from TOYOBO Corporation).

[0050] The amplification conditions are: 94°C, 2min, 94°C, 45sec, 55°C, 45sec, 68°C, 90sec, 30 cycles.

[0051] The 1.5kb PCR product of the pheA mutant gene fragment was rec...

Embodiment 2

[0064] Example 2 Preparation of bacterial strain CGSC7692 (ΔtyrA) with knockout of tyrA gene

[0065] 1. Preparation of mutant strain CGSC7692 (ΔtyrA::Kan)

[0066] Using the CGSC10049 (ΔtyrA::Kan) genome as a template, primers tyrA-V-F and tyrA-V-R were used to amplify the tyrA mutant gene fragment by PCR. increase method):

[0067] Forward primer tyrA-V-F: 5'-TATCCGTAACCGATGCCTGC-3' (SEQ ID NO: 4)

[0068] Reverse primer tyrA-V-R: 5'-GGGAAATCACCCGTTCAATG-3' (SEQ ID NO: 5)

[0069] The 1.5kb PCR product of the tyrA mutant gene was recovered by gel (refer to the recovery method of the Hangzhou Aisijin Kit for gel recovery), and the PCR product was transformed into E. coli CGSC7692 / pKD46 by electric shock transformation (electric transformation conditions: 2.5kV, 200Ω, 25μF). In state cells (the method is the same as described in Example 1), culture in LB medium at 37°C for 1 to 2 hours, spread the bacterial solution on a solid LB plate containing kanamycin (100 μg / ml), 37 ...

Embodiment 3

[0080] Example 3 Preparation of strain CGSC7692 (ΔtrpR) with knockout trpR gene

[0081] 1. Preparation of mutant strain CGSC7692 (ΔtrpR::Kan)

[0082] Using the CGSC11110 (ΔtrpR::Kan) genome as a template, using primers trpR-V-F and trpR-V-R, PCR amplifies the trpR mutant gene fragment, and the primer sequence is as follows (the reagents and reaction system used for PCR are the same as the gene amplification method in Example 1) :

[0083] Forward primer trpR-V-F: 5'-ATGGGGGATAAACCGACGTT-3' (SEQ ID NO: 7)

[0084] Reverse primer trpR-V-R: 5'-ATGCCGTGTATTAAGCGCCT-3' (SEQ ID NO: 8)

[0085] The 1.5kb PCR product of the trpR mutant gene was recovered by gel (refer to the recovery method of the Hangzhou Aisin Kit for gel recovery), and the PCR product was transformed into E. coli CGSC7692 / pKD46 by electric shock transformation (electric transformation conditions: 2.5kV, 200Ω, 25μF). In state cells (the method is the same as that in Example 1), culture in LB medium at 37°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com