Rhenium-containing Ni3Al-based single crystal alloy

A technology based on single crystal and alloy, applied in the field of alloy, can solve the problem of alloy oxidation resistance, and achieve the effect of high-temperature lasting strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

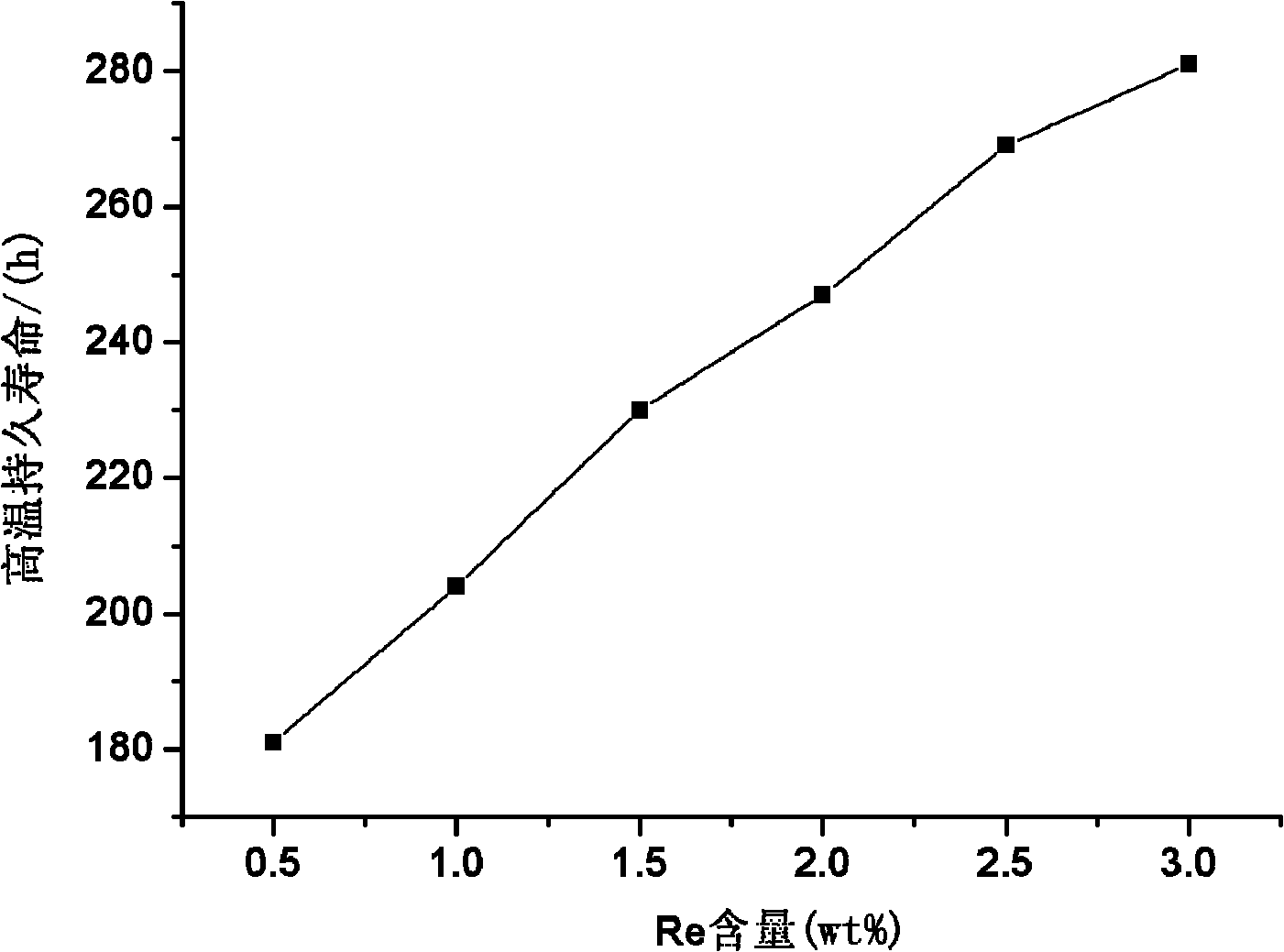

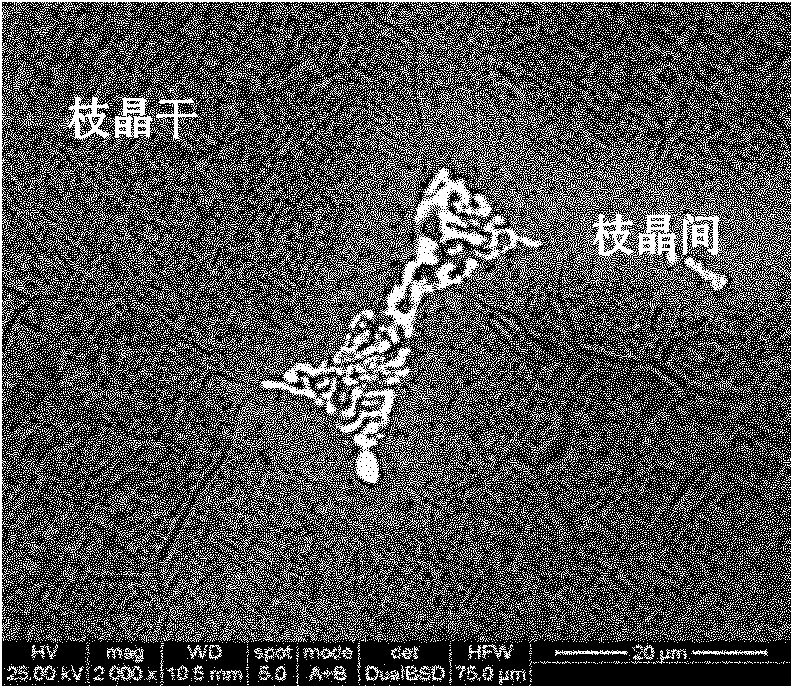

[0031] A kind of rhenium-containing Ni that the present invention proposes 3 Al-based single crystal alloy, the composition of which is 7-8wt% of Al, 8-13% of Mo, 0.0005-3wt% of Re, and the rest is Ni by weight percentage; the Ni containing rhenium 3 The Al-based single crystal alloy may also contain more than one Dy, Y or Hf, and the composition is 0.05-0.5wt% Dy, 0.1-1wt% Y or 0.05-0.5wt% Hf. The content of Re is preferably 0.5-3 wt%, more preferably 1-2 wt%. The rhenium-containing Ni 3 Al-based single crystal alloys include three phase structures of γ′ phase, γ phase and rhenium-containing NiMo phase in the as-cast state. The present invention proposes that the rhenium-containing Ni 3 The Al-based single crystal alloy is prepared by the following preparation method, which specifically includes the following steps:

[0032] The first step: preparing liquid metal cooling medium;

[0033] The liquid metal cooling medium is gallium indium alloy or metal tin. The preparati...

Embodiment 1

[0049] A rhenium-containing Ni 3 The composition of the Al-based single crystal alloy, the weight percentage of each element is: 7.4wt% Al, 13% Mo, 0.5% Re, 0.1wt% Dy, 0.1wt% Y, and the rest is Ni. The rhenium-containing Ni 3 Al-based single crystal alloys include three phase structures of γ′ phase, γ phase and rhenium-containing NiMo phase in the as-cast state.

[0050] The rhenium-containing Ni3 The preparation method of Al-based single crystal alloy mainly comprises the following steps:

[0051] The first step: preparing liquid metal cooling medium;

[0052] The liquid metal cooling medium is gallium indium alloy. The preparation of the gallium-indium alloy: the raw materials high-purity gallium (Ga) and high-purity indium (In), by weight percentage: gallium 10wt%, the rest is indium, weighed, put into a beaker and heated to 80 ° C to make it After the reaction is in a liquid state, pour it into a liquid metal cooling tank as a cooling medium, and use vacuum pump oil to...

Embodiment 2

[0065] A rhenium-containing Ni 3 The composition of the Al-based single crystal alloy, the weight percentage of each element is: 7.5wt% Al, 11% Mo, 1% Re, 0.05wt% Dy, 0.5wt% Y, and the rest is Ni.

[0066] The rhenium-containing Ni 3 The preparation method of Al-based single crystal alloy specifically comprises the following steps:

[0067] The first step: preparing liquid metal cooling medium;

[0068] The liquid metal cooling medium is gallium indium alloy or metal tin. The preparation of the gallium-indium alloy: the raw materials high-purity gallium (Ga) and high-purity indium (In), by weight percentage: gallium 30wt%, the rest is indium, weighed, put into a beaker and heated to 200 ° C to make it After the reaction is in a liquid state, pour it into a liquid metal cooling tank as a cooling medium, and use vacuum pump oil to heat the liquid metal cooling tank to maintain the temperature of the cooling tank at 18°C, so that the gallium-indium alloy remains liquid;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com