Horizontal light emitting diode and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced luminous efficiency, troublesome manufacturing process, and difficult alignment, so as to reduce forward bias voltage, easy manufacture, and increase luminescence benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The detailed content and technical description of the present invention are further described by examples, but it should be understood that the following examples are only for illustrative purposes, and should not be construed as limitations to the implementation of the present invention.

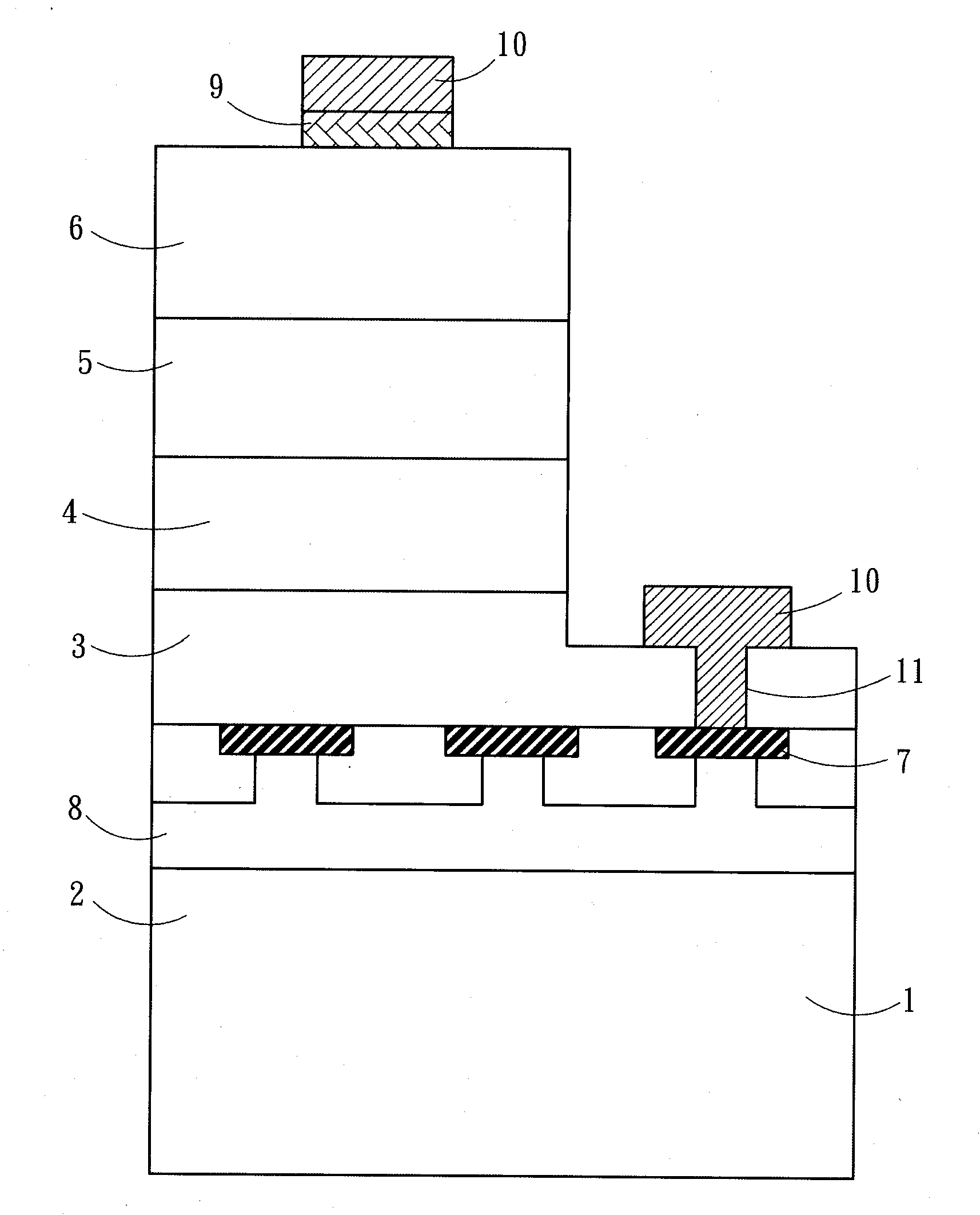

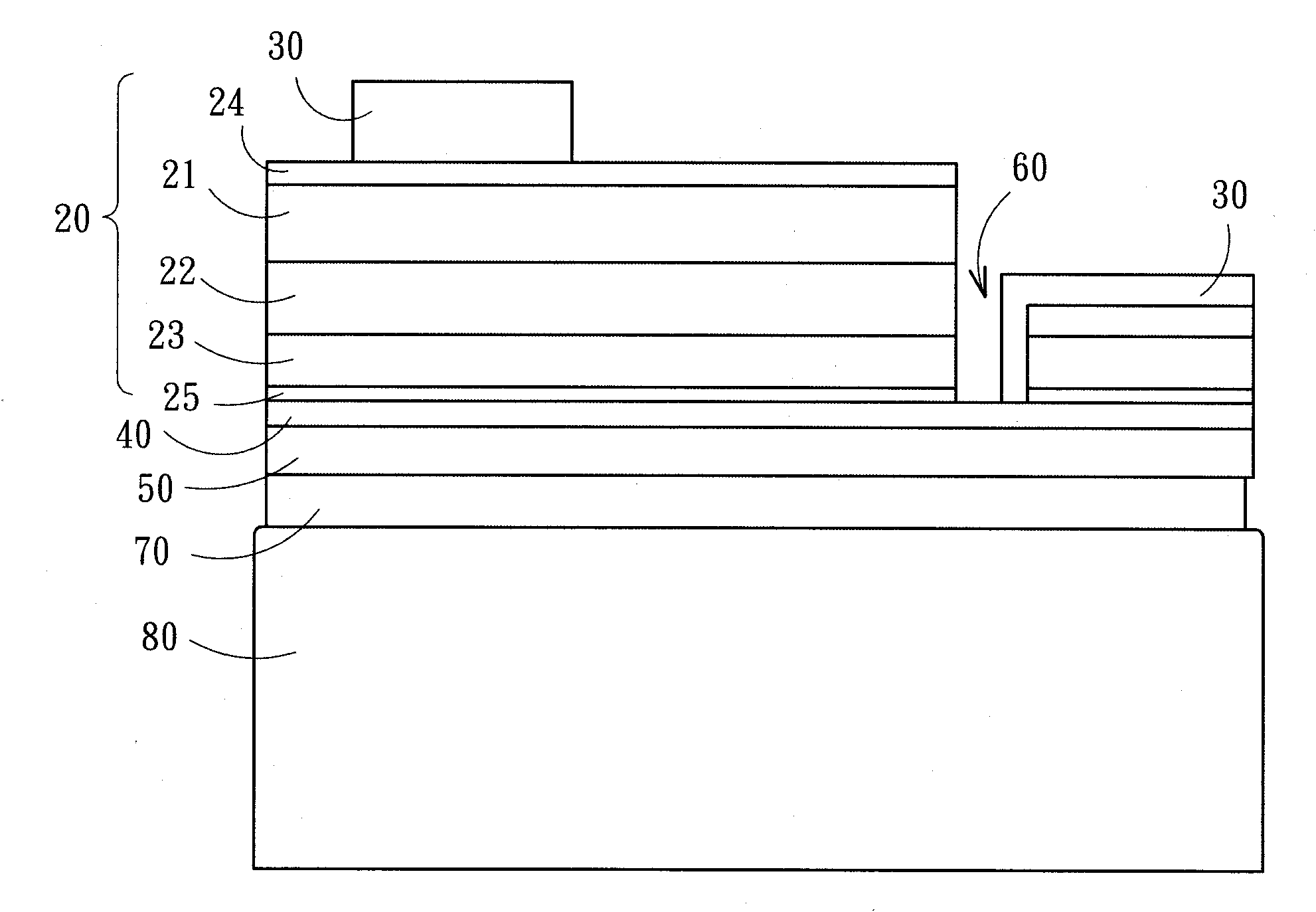

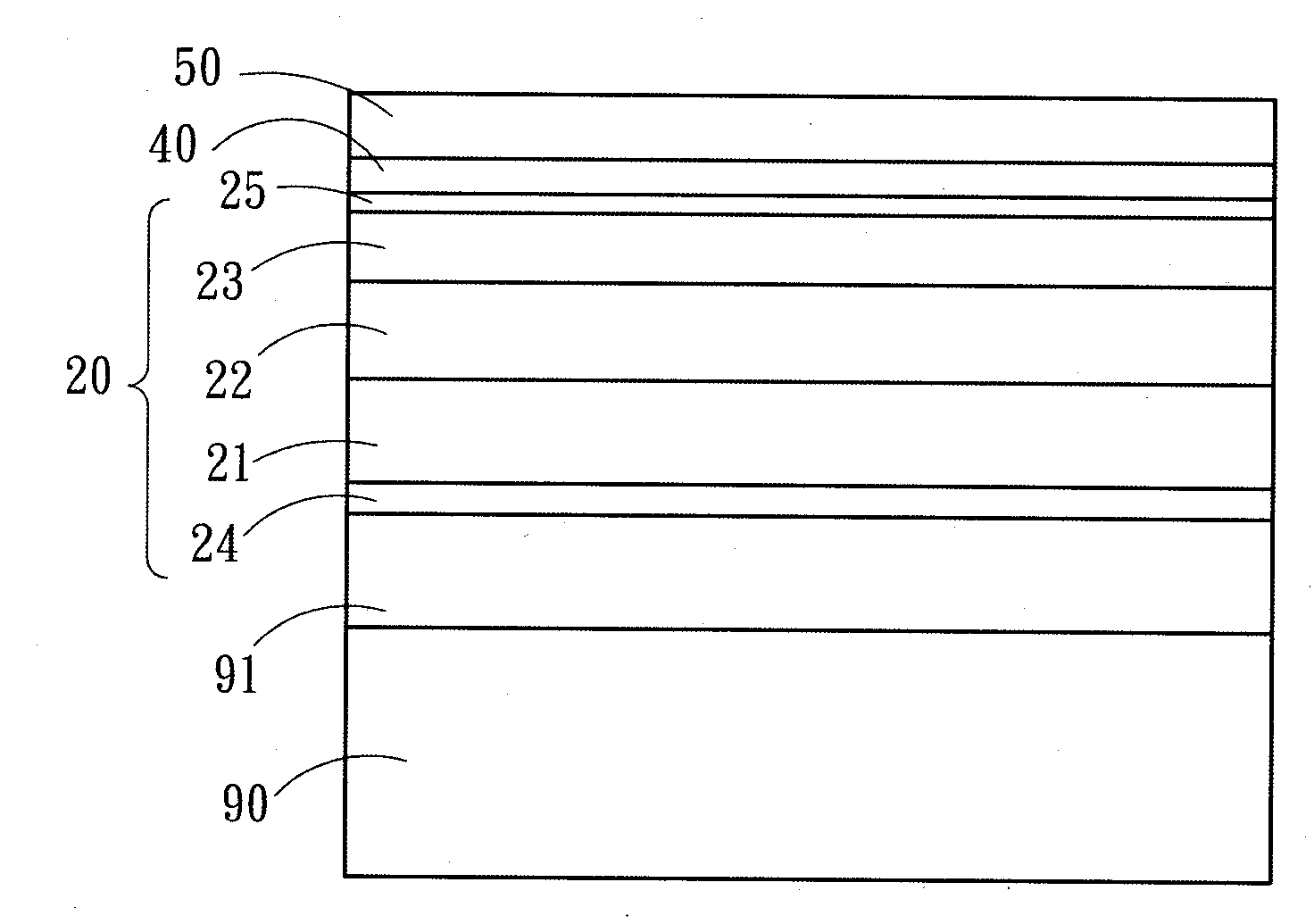

[0016] see figure 2 As shown, it is an embodiment of the present invention, which includes a light-emitting laminated layer 20, a transparent conductive layer 40, a high reflection layer 50, an electrical connection channel 60 and two stitching electrode layers 30, wherein the light-emitting laminated layer 20 may have a first ohmic contact layer 24, an upper cladding layer 21, an active layer 22, a lower cladding layer 23 and a second ohmic contact layer 25 formed in sequence, wherein the active layer 22 is aluminum phosphide Gallium indium epitaxy (AlGaInP) structure or aluminum gallium indium nitride epitaxy structure, and the upper cladding layer 21 can be P-type aluminum galliu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com