Single coating uv ultraviolet light curing color effect paint applied on plastic substrate and its preparation

A UV and light-curing technology, applied in coatings, polyester coatings, polyether coatings, etc., can solve problems such as non-drying of coating films, incomplete polymerization of photo-curable resins and reactive diluents, and insufficient activity of photoinitiators , to achieve the effect of small molecular weight, improved wear resistance and chemical resistance, and high unit density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method for a single-coated UV ultraviolet photocuring color effect paint applied to a plastic base material, the method comprising the following steps:

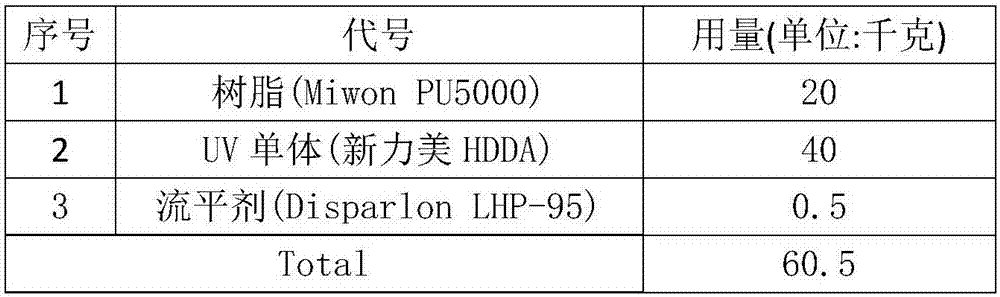

[0041] (1) Preparation of mixture A:

[0042]

[0043] (i) Add the resin, UV monomer, and leveling agent into the small bucket first according to the formula requirements, and stir at 800-900 rpm, stir for 5-10 minutes, and keep the temperature at 30-50°C;

[0044] (2) Preparation of mixture B:

[0045]

[0046] (ii) Add pearlescent pigment, nano-color paste, photoinitiator, and photosensitizer into the large tank according to the formula requirements, stir at 800-1200 rpm for 5-10 minutes, and keep the temperature at 30-50°C;

[0047] (iii) The mixture obtained in the sampling step (ii) is tested for cleanliness, and the scraper paper is scraped with a 100um wet film preparation device, and there are no obvious particles on the scraper paper;

[0048] (iv) Add the mixture obtained in step (i) int...

Embodiment 2

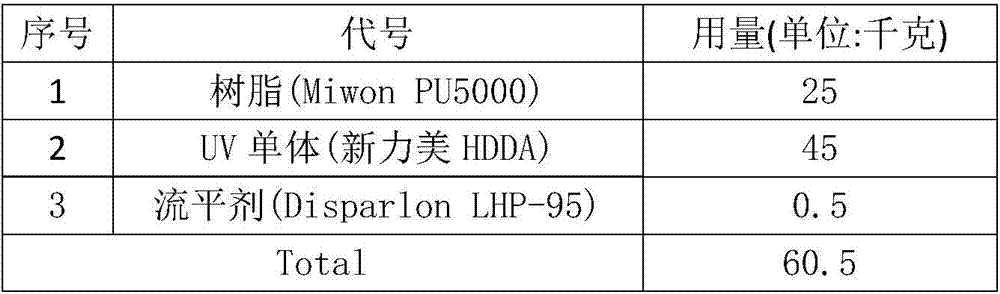

[0052] (1) Preparation of mixture A:

[0053]

[0054] (i) Add the resin, UV monomer, and leveling agent into the small bucket first according to the formula requirements, and stir at 800-900 rpm for 5-10 minutes, keeping the temperature at 30-50°C;

[0055] (2) Preparation of mixture B:

[0056]

[0057] (ii) Add pearlescent pigments, colorants, photoinitiators, and photosensitizers into the vat according to the recipe requirements, stir at 800-1200 rpm for 5-10 minutes, and keep the temperature at 30-50°C;

[0058] (iii) Sampling (ii) To test the cleanliness, use a 100um wet film preparer to scrape on the scraper paper, and there are no obvious particles on the scraper paper;

[0059] (iv) Add (i) into (ii), stir at 800-900 rpm for 5-10 minutes;

[0060] (v) Sampling (iv) Check the cleanliness. After there are no obvious particles, use the Iwata #2 cup to check and adjust to the range of 9 to 10 seconds;

[0061] (vi) filter, weigh and pack.

Embodiment 3

[0063] (1) Preparation of mixture A:

[0064]

[0065] (i) Add the resin, UV monomer, and leveling agent into the small bucket first according to the formula requirements, and stir at 800-900 rpm for 5-10 minutes, keeping the temperature at 30-50°C;

[0066] (2) Preparation of mixture B:

[0067]

[0068] (ii) Add pearlescent pigments, colorants, photoinitiators, and photosensitizers into the vat according to the recipe requirements, stir at 800-1200 rpm for 5-10 minutes, and keep the temperature at 30-50°C;

[0069] (iii) Sampling (ii) To test the cleanliness, use a 100um wet film preparer to scrape on the scraper paper, and there are no obvious particles on the scraper paper;

[0070] (iv) Add (i) into (ii), stir at 800-900 rpm for 5-10 minutes;

[0071] (v) Sampling (iv) Check the cleanliness. After there are no obvious particles, use the Iwata #2 cup to check and adjust to the range of 9 to 10 seconds;

[0072] (vi) filter, weigh and pack.

[0073] When using thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com