Electroconductive connecting material, method for connecting terminals to each other using the electroconductive connecting material, and method for manufacturing connecting terminal

A conductive connection material and resin composition technology, which is applied in the direction of conductive connection, electrical component connection, printed circuit manufacturing, etc., can solve the problems of inability to print, high cost of solder ball production, and difficulty in making small-diameter solder balls. High conductivity and excellent connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

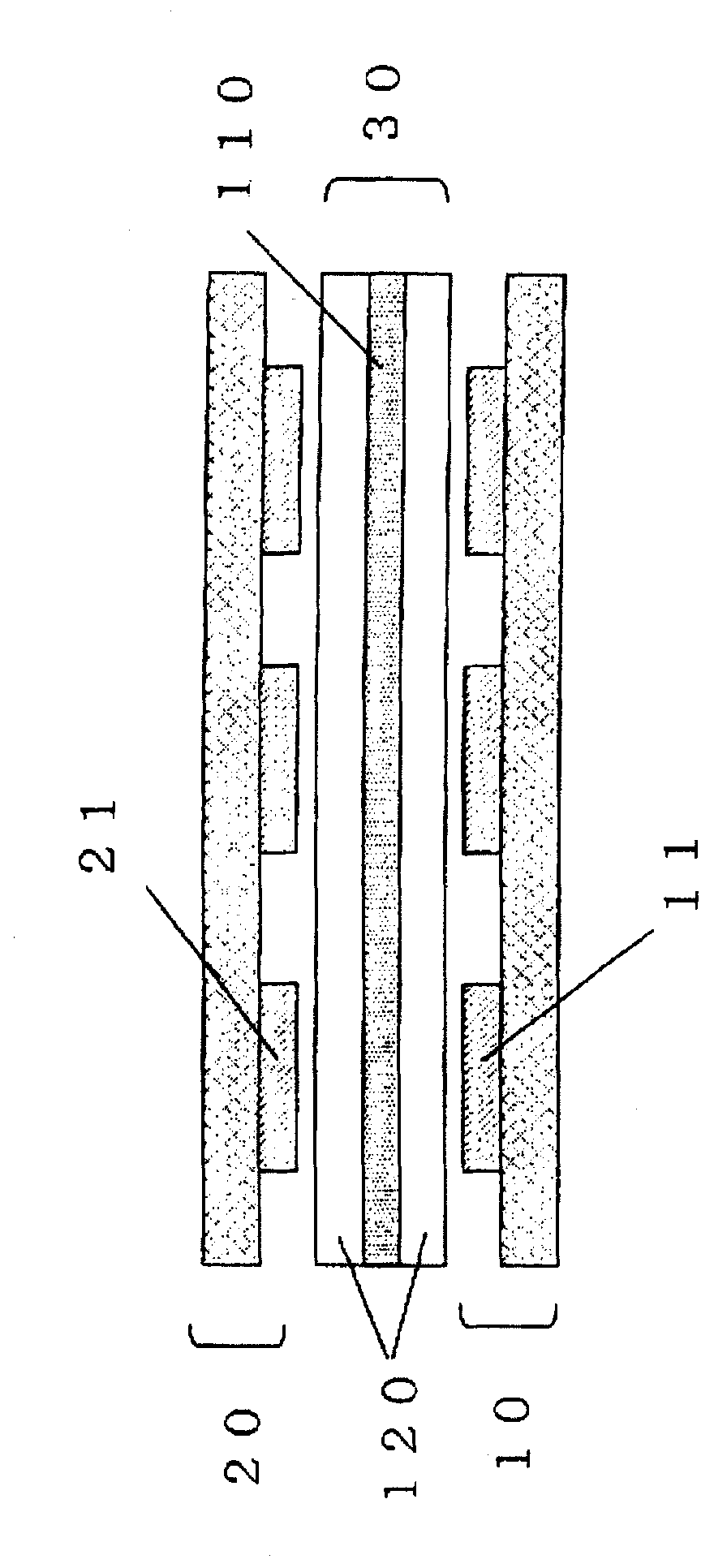

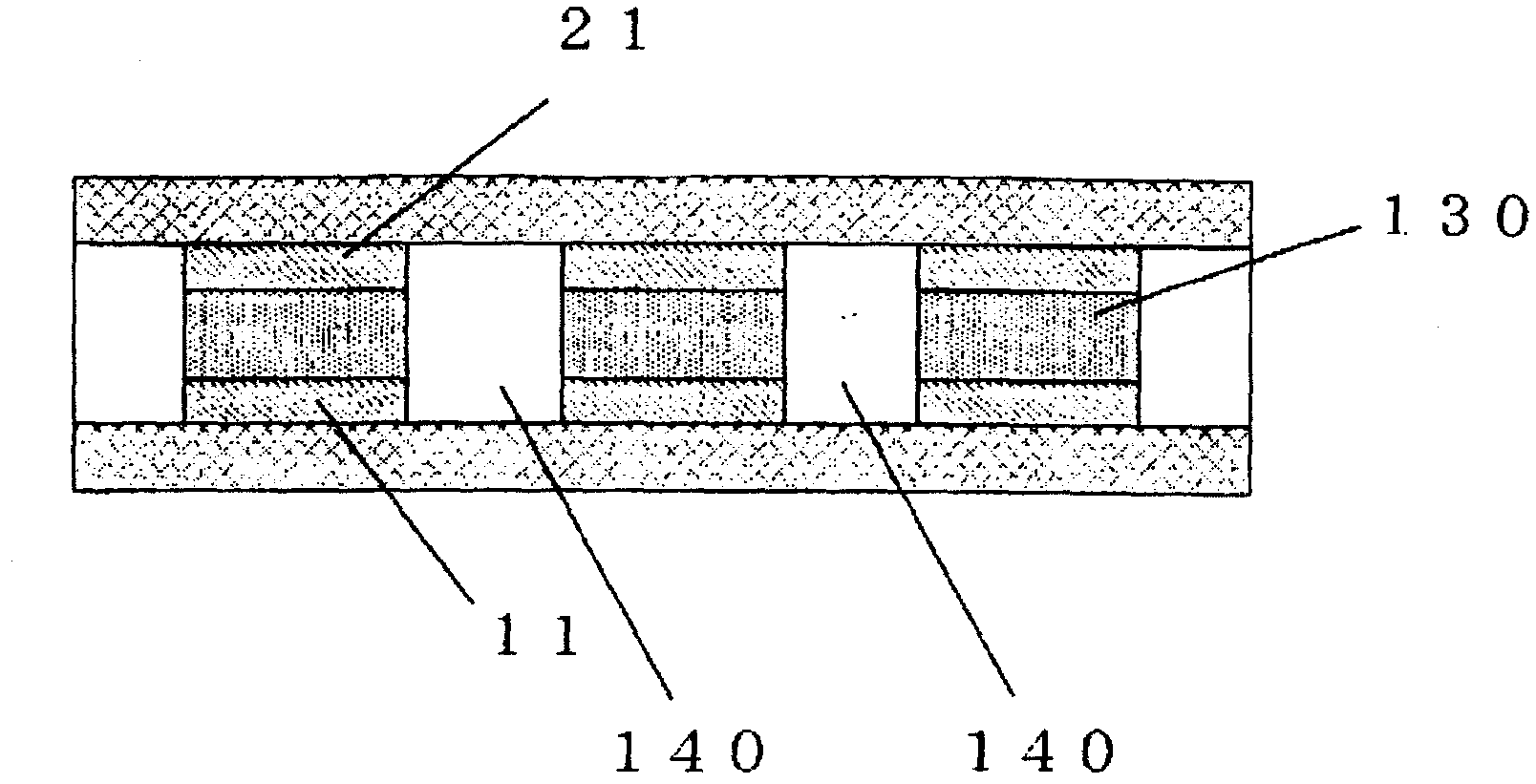

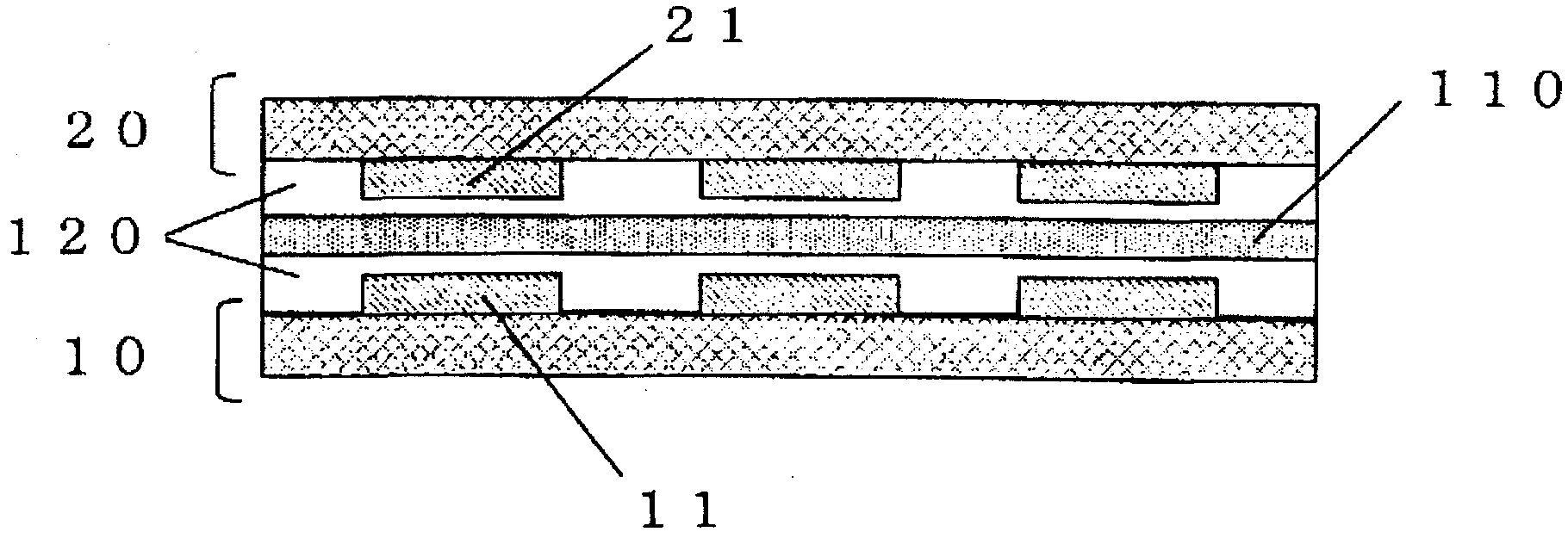

[0210]The connection method between terminals according to the first embodiment of the present invention includes: arranging a conductive connection material containing the aforementioned curable resin composition and metal foil between the terminals; a temperature at which the curing of the curable resin composition does not end; a heating step of heating the conductive connecting material; and a curing step of curing the curable resin composition.

[0211] In this connection method, heat-melted solder or tin is selectively aggregated between terminals to form a conductive region, and a curable resin composition is used to form an insulating region around it. As a result, insulation between adjacent terminals can be ensured to prevent leakage current, and thus the connection reliability of the connection between the terminals can be improved. In addition, electrical connection between a plurality of terminals can be performed at once even in a fine wiring circuit. Furthermor...

no. 2 approach

[0225] Next, a connection method between terminals according to a second embodiment of the present invention will be described. The terminal-to-terminal connection method according to the second embodiment of the present invention includes: arranging a conductive connection material containing the aforementioned thermoplastic resin composition and metal foil between opposing terminals; and a heating step of heating the conductive connecting material at a temperature at which the thermoplastic resin composition softens; and a curing step of curing the thermoplastic resin composition. Next, each step will be described.

[0226] (a) Configuration process

[0227] In the case of using a conductive connecting material containing a thermoplastic resin composition and metal foil, the conductive connecting material can also be arranged in the same manner as in the case of using the conductive connecting material containing the aforementioned thermosetting resin composition and metal ...

Embodiment 1

[0302] 39.3 parts by weight of epoxy resin ("EPICLON EXA830-LVP" manufactured by Dainippon Ink Chemical Industry Co., Ltd., epoxy equivalent 160g / eq), carboxyl-terminated butadiene-acrylonitrile copolymer (Ube Industries, Ltd.) manufactured "CTBN1008-SP") 0.8 parts by weight, gentisic acid (manufactured by Midori Kagaku Co., Ltd) 7.9 parts by weight, sebacic acid (manufactured by Tokyo Chemical Industry Co., Ltd.) 2.0 parts by weight, and 2-phenyl-4 - 0.2 parts by weight of methylimidazole ("Curezol 2P4MZ" manufactured by Shikoku Chemical Industry Co., Ltd.) was mixed to prepare a curable resin composition. The melt viscosity (160° C.) of the obtained curable resin composition was measured according to the method described above. The results are shown in Table 1.

[0303] This curable resin composition was coated on a solder foil (Sn / Bi=42 / 58, density=8.7g / cm 3 , thickness of 10 μm) on both sides, a thickness of 50 μm conductive connection material was produced.

[0304] Ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com