Bent member for bamboo furniture and manufacturing method thereof

A production method and bending technology, applied in the direction of manufacturing tools, wood processing appliances, etc., can solve problems such as affecting the development of the furniture industry, unfavorable low-carbon environmental protection, and long time to produce wood, and achieve the effects of dimensional stability, small deformation, and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

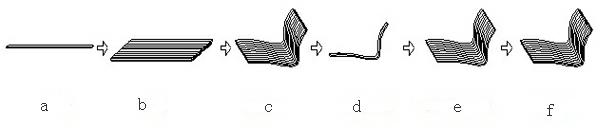

[0038] The concrete steps of a kind of manufacturing method of bamboo furniture bending member are:

[0039] (1) Bamboo slices: choose moso bamboo slices, planed on the surface;

[0040] (2) Cooking and softening: Steam the bamboo slices for 4 hours and the pressure is 0.6Mpa to soften the bamboo slices;

[0041] (3) Folding: The string surface of the softened bamboo slices is tightly stacked, and the adjacent layers of bamboo slices should be differently jointed to improve the bonding strength;

[0042] (4) Putting into the mold: Put the folded bamboo slices into the wooden mold at a temperature of 90°C and a humidity of 85%;

[0043] (5) Microwave heating and bending: heat the bamboo slices stacked in a wooden mold with a microwave at a heating temperature of 90°C for 5 minutes, with a microwave power of 0.9kW, and uniformly and slowly pressurize at a pressure of 1.0MPa. It is clamped and fixed together with the wooden mold;

[0044] (6) Pressurized drying and shaping: pu...

Embodiment 2

[0051] The concrete steps of a kind of manufacturing method of bamboo furniture bending member are:

[0052](2) Cooking and softening: the time is 6 hours, the pressure is 0.8Mpa, and the bamboo chips are softened;

[0053] (4) Putting into the mold: Put the folded bamboo slices into the wooden mold at a temperature of 100°C and a humidity of 98%;

[0054] (5) Microwave heating and bending: heat the bamboo slices stacked in a wooden mold with microwaves at a temperature of 130°C for 1 minute, with a microwave power of 5kW, and uniformly and slowly pressurize at a pressure of 3.0MPa. Clamp and fix together with the wooden mold;

[0055] (6) Pressure drying and shaping: drying at 145°C; pressure 3.0MPa;

[0056] (7) Glue coating and blank matching: the amount of glue coating is 250g / m 2 .

[0057] (8) Aging: Aging the surface blank of the curved horizontal panel prepared in step (7), the aging time is 20 minutes, and then put it into a wooden mold and pressurize it for faste...

Embodiment 3

[0063] The concrete steps of a kind of manufacturing method of bamboo furniture bending member are:

[0064] (2) Cooking and softening: Steam the bamboo slices for 5 hours and the pressure is 0.7Mpa to soften the bamboo slices;

[0065] (4) Putting into the mold: Put the folded bamboo pieces into the wooden mold at a temperature of 95°C and a humidity of 90%;

[0066] (5) Microwave heating bending: the heating temperature is 100°C, the heating time is 3 minutes, the microwave power is 4kW, and the pressure is uniformly and slowly applied, and the pressure is 2.0MPa;

[0067] (6) Pressurized drying and shaping: put the folded bamboo slices together with the wooden mold into the drying box, and dry at 140°C; the pressure is 2.6M;

[0068] (7) Glue coating and blank matching: the amount of glue coating is 200g / m 2 .

[0069] (8) Aging: Aging the curved horizontal slab face blank prepared in step (7), the aging time is 18 minutes, and then put it into a wooden mold and pressuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com