Method for smelting clean steel by supplementation and decarburization with CO2 at end of converter blowing

A smelting method and converter blowing technology are applied in the field of clean steel smelting where CO2 supplementary decarburization is used in the final stage of converter blowing to achieve the effects of reducing the number of inclusions, temperature loss and FeO content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

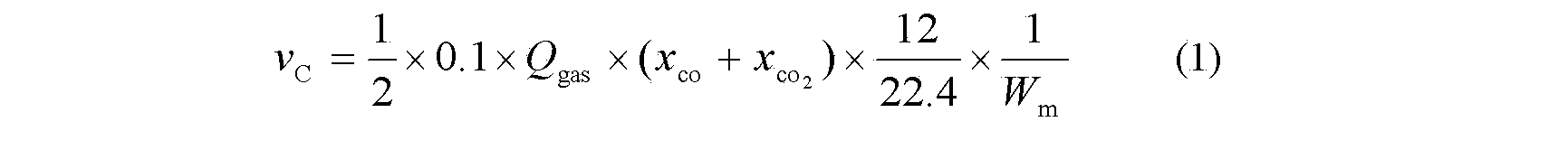

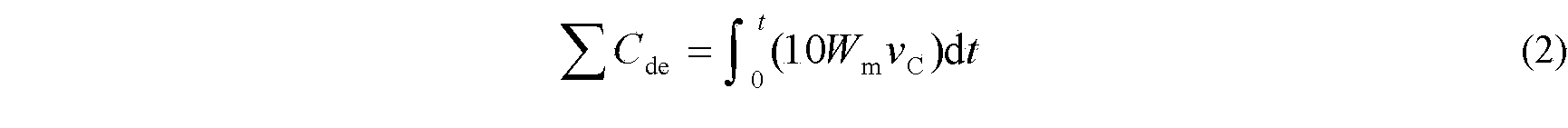

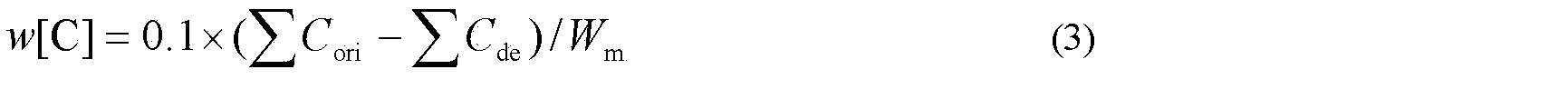

[0034] (1) The total amount of oxygen consumption is controlled by a mathematical model. When the blowing reaches 80% of the total oxygen consumption, the first gas switching judgment is made. At this time, the decarburization rate has not yet dropped to 50% of the severe decarburization period. Continue to blow oxygen;

[0035] (2) When the blowing reaches 88% of the total oxygen consumption, the second gas switching judgment is made. At this time, the decarburization rate has dropped to 50% of the severe decarburization period, and the mathematical model judges that the carbon content is 0.24%. When the gas injection is carried out by O 2 switch to O 2 with CO 2 mixed gas, CO 2 The content accounts for 11% of the air blowing volume, and the air supply intensity is 2.0Nm 3 / t min;

[0036] (3) When the measured carbon content is 0.072%, stop blowing;

Embodiment 2

[0038] (1) The total amount of oxygen consumption is controlled by a mathematical model. When blowing reaches 85% of the total oxygen consumption, the first gas switching judgment is made. At this time, the decarburization rate has not yet dropped to 50% of the severe decarburization period. Continue to blow oxygen;

[0039] (2) When the blowing reaches 90% of the total oxygen consumption, the second gas switching judgment is made. At this time, the decarburization rate has dropped to 50% of the severe decarburization period. The mathematical model judges that the carbon content is 0.18%. gas, that completes the blown gas by O 2 Switch to O 2 with CO 2 mixed gas, CO 2 The content accounts for 14% of the air blowing volume, and the air supply intensity is 2.0Nm 3 / t min;

[0040] (3) When the measured carbon content is 0.06%, stop blowing;

Embodiment 3

[0042] (1) The total amount of oxygen consumption is controlled by the mathematical model. When the blowing reaches 90% of the total oxygen consumption, the first gas switching judgment is made. At this time, the decarburization rate has not yet dropped to 50% of the severe decarburization period. Continue to blow oxygen;

[0043] (2) When the blowing reaches 92% of the total oxygen consumption, the second gas switching judgment is made. At this time, the decarburization rate has dropped below 50% of the severe decarburization period, and the mathematical model judges that the carbon content is 0.12%. switch gas, i.e. finish blowing gas by O 2 Switch to O 2 with CO 2 mixed gas, CO 2 The content accounts for 18% of the air blowing volume, and the air supply intensity is 2.0Nm 3 / t min;

[0044] (3) When the measured carbon content is 0.072%, stop blowing;

[0045] The implementation results are listed in Table 2. The blowing is controlled smoothly during the operation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com