Dredger fill sludge dewatering and solidification method

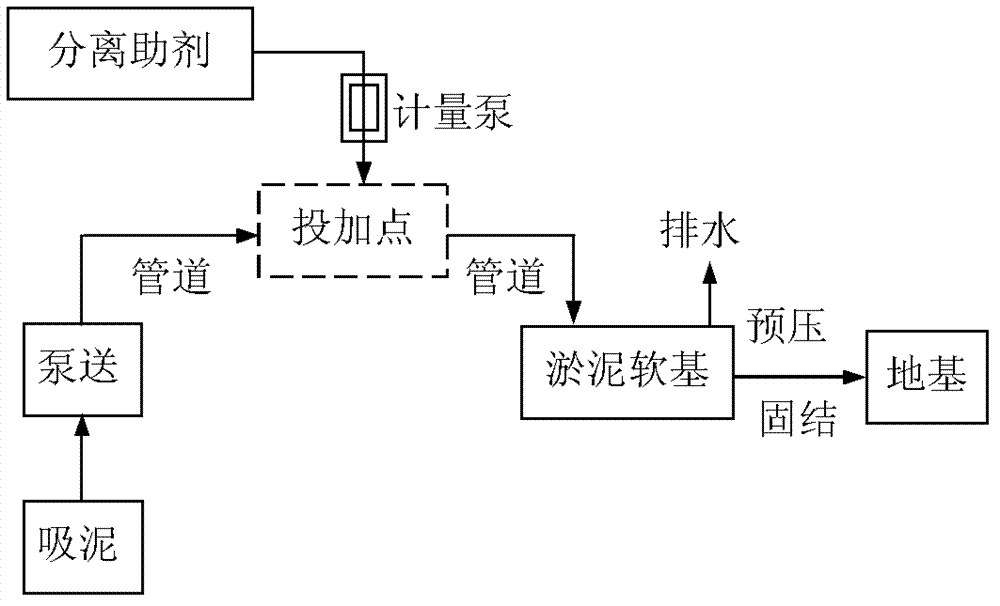

A technology of drainage consolidation and dredging mud filling, which is applied in the fields of water filling, soil protection, infrastructure engineering, etc., can solve the problems of high water content of dredging mud, long time-consuming drainage and consolidation, and difficulty in mud-water separation, etc., to achieve Enhance the effect of mud-water separation, improve drainage efficiency, and speed up the effect of mud-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] A certain place along the southeast coast of China needs to be filled with land, and it is planned to use hydraulic filling and vacuum preloading methods. The marine silt in this sea area has a water content of 105% and a bulk density of 1.5 tons / m 3 , Party A requires to complete the dredging and filling project in the shortest possible time, and requires the bearing strength of the foundation to reach 200 kPa. The project uses two 2500 m 3 / h cutter suction dredger 12 hours of operation. In order to solve the problems such as long time required for natural solid-liquid separation of dredged fill sludge in the landfill, and a large amount of sludge taken away by the backwater discharge, during the project implementation process, the drainage of dredged fill sludge was improved by injecting separation aids on the conveying pipeline. Consolidation speed and effect. The specific implementation method is:

[0025] 1. Divide the partition wall of the dredging filling ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com