A kind of water-based primer and construction technology thereof

A water-based primer and construction technology, applied in primers, coatings, polyurea/polyurethane coatings, etc., can solve the problems of insufficient appearance, high cost, and long grinding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention is a water-based primer, which includes water-based polyolefin resin, unsaturated carboxylic acid or acid anhydride modified polyolefin, water-based epoxy resin, water-based acrylic resin, and the weight ratio of primer and curing agent is 100:10. Unsaturated carboxylic acid or acid anhydride modified polyolefin is polyolefin modified with maleic acid or maleic anhydride, the mass ratio of each component is calculated based on solid content: 10 to 30 parts of water-based polyolefin resin, 25 parts ~40 parts of unsaturated carboxylic acid or anhydride modified polyolefin, 5~10 parts of water-based epoxy resin, 15-20 parts of water-based acrylic resin; the curing agent is at least one polyisocyanate with a weight percentage of 40-70 parts curing agent and 15-70 parts of γ-butyrolactone. The hydroxyl value of water-based acrylic resin is 10-70mgKOH / g, and the acid value is 80-120mgKOH / g. The unsaturated carboxylic acid or acid anhydride modified polyolefin h...

Embodiment 2

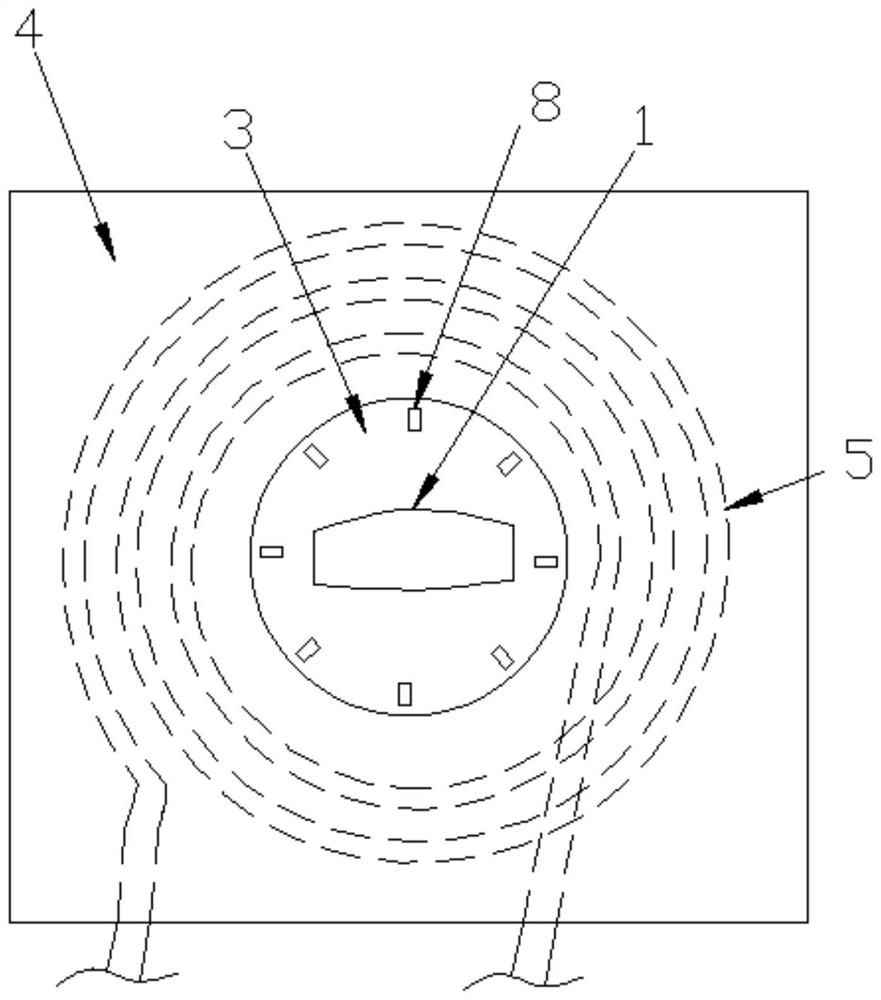

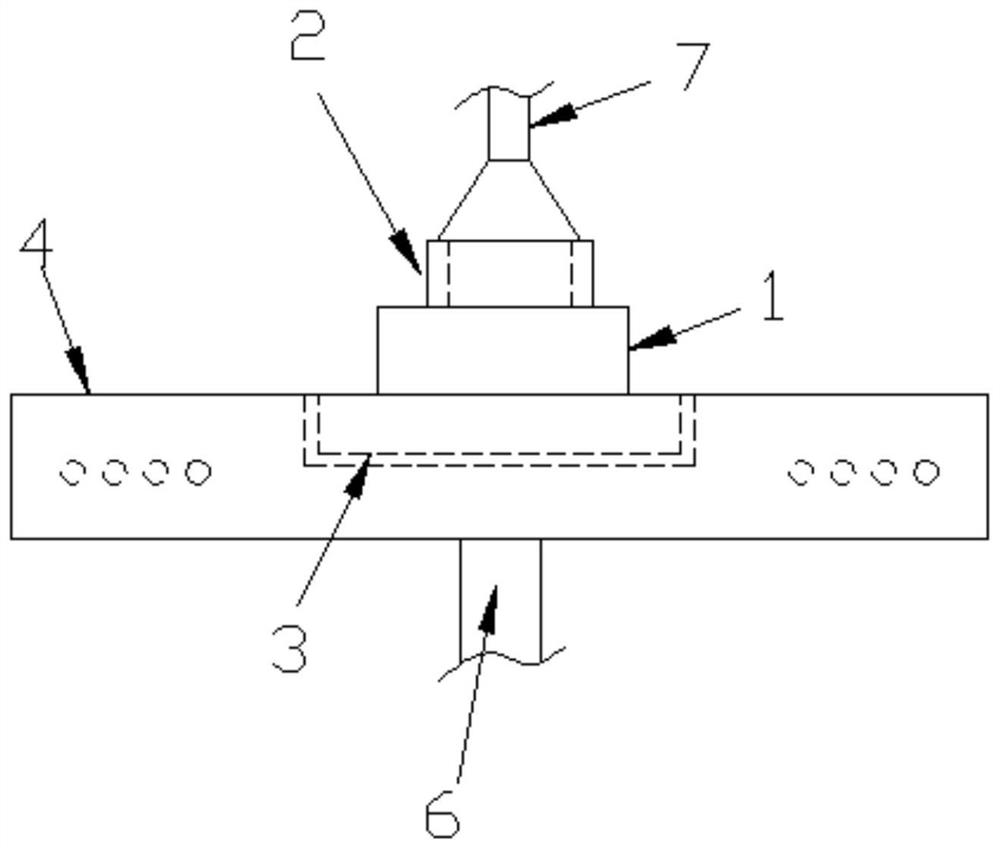

[0033] The difference from Embodiment 1 is that, as figure 1 , figure 2 Shown, the construction technique of water-based primer comprises the following steps:

[0034] Stir each component of the above-mentioned weight content without foam for more than 15 minutes, adopt the spot coating method, and then rotate the workpiece 1 after spot-coating the primer on the workpiece 1, and select a suitable primer for spot coating according to the shape of the pattern on the final painted workpiece 1 The amount and the rotation speed of the workpiece 1; and the workpiece 1 is dried when the workpiece 1 is rotated, and the drying time is 10 minutes; the drying temperature is 80°C. In the dispensing process, a profiling annular baffle plate 2 that is relatively stationary relative to the rotating workpiece 1 is set against the workpiece 1 . A circular turntable 3 is set under the workpiece 1, and the circular turntable 3 is rotated and set on the square base 4. The middle part of the sq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com