Determination method for hydration rate curve of electrical steel dedicated magnesium oxide

A measurement method and magnesium oxide technology, applied in the direction of removing a certain component and weighing, etc., can solve the problem of incomplete correspondence, etc., and achieve the effect of simple operation and accurate results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] instrument:

[0029] One 200ml beaker; one thermostat box; one electric furnace; one oven; one muffle furnace; one stopwatch Reagents:

[0030] Magnesium oxide to be tested; distilled water

[0031] Experimental steps:

[0032] 1. Weigh 20 grams of magnesium oxide into a 200ml beaker, add 150ml of distilled water and stir well.

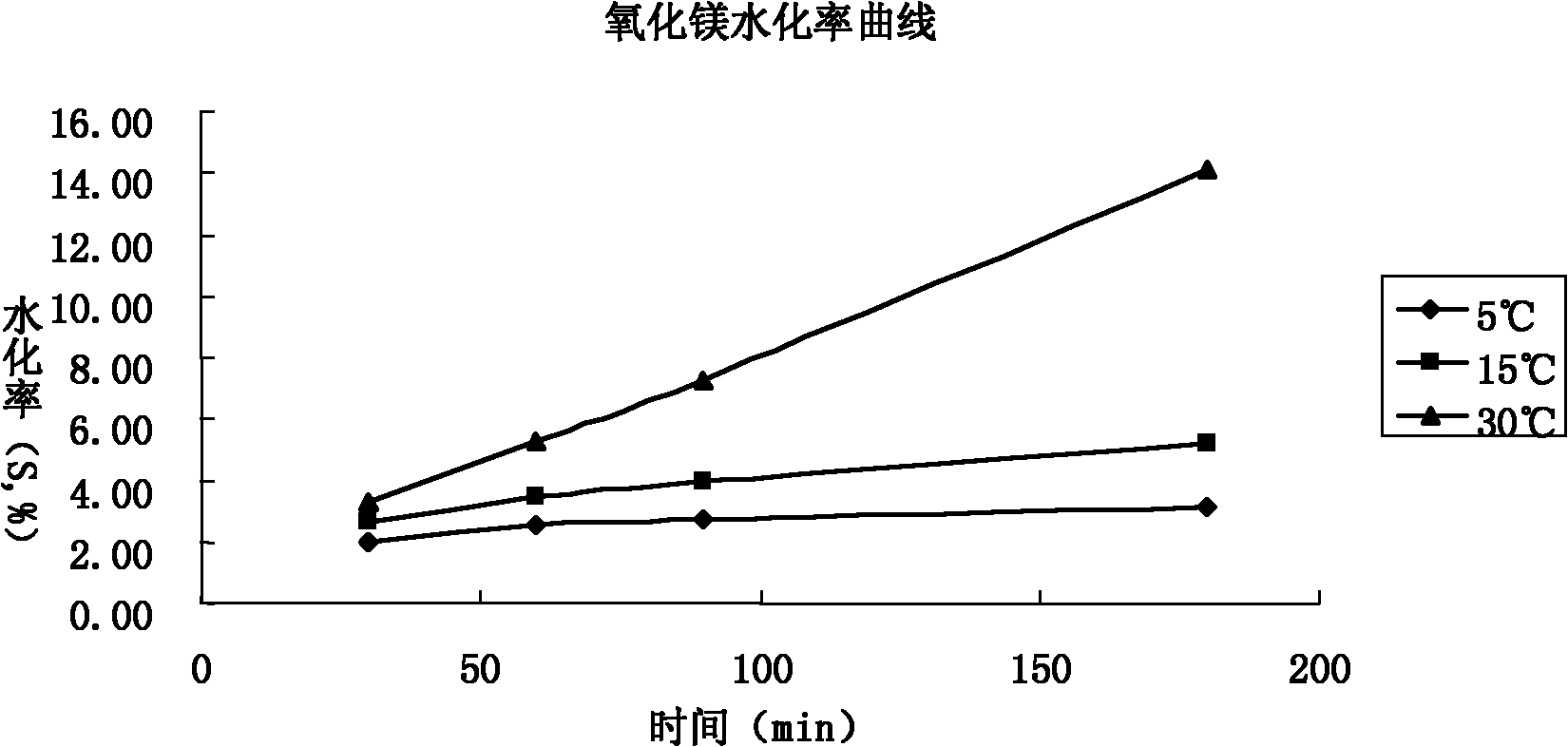

[0033] 2. Put the beaker in the incubator (set at 5°C, 15°C, and 30°C respectively).

[0034] 3. At 30, 60, 90, and 180 minutes, apply the stirred slurry thinly and evenly on the steel plate.

[0035] Dry on electric oven.

[0036] 4. Scrape the magnesium oxide off the steel plate, put it in a weighing bottle and store it in a desiccator.

[0037] 5. Keep the crucible at constant weight.

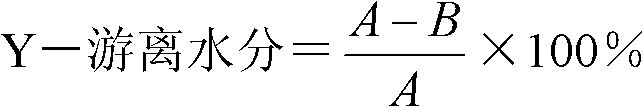

[0038] 6. Weigh about 1 gram of magnesium oxide and record it as A, put it in a porcelain crucible with constant weight, keep it in an oven at 110°C for 1 hour, weigh it after cooling and record it as B, and calculate the free water.

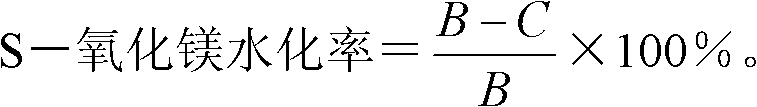

[0039] 7. Then k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com