SOI-LIGBT (silicon on insulator-lateral insulated gate bipolar transistor) device with split anode structure

An anode structure and anode technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of slow turn-off time of SOI-LIGBT, increased cost of integrated circuits, large on-resistance, etc., and achieve the elimination of negative differential resistance area, Excellent conduction loss, increase the effect of on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

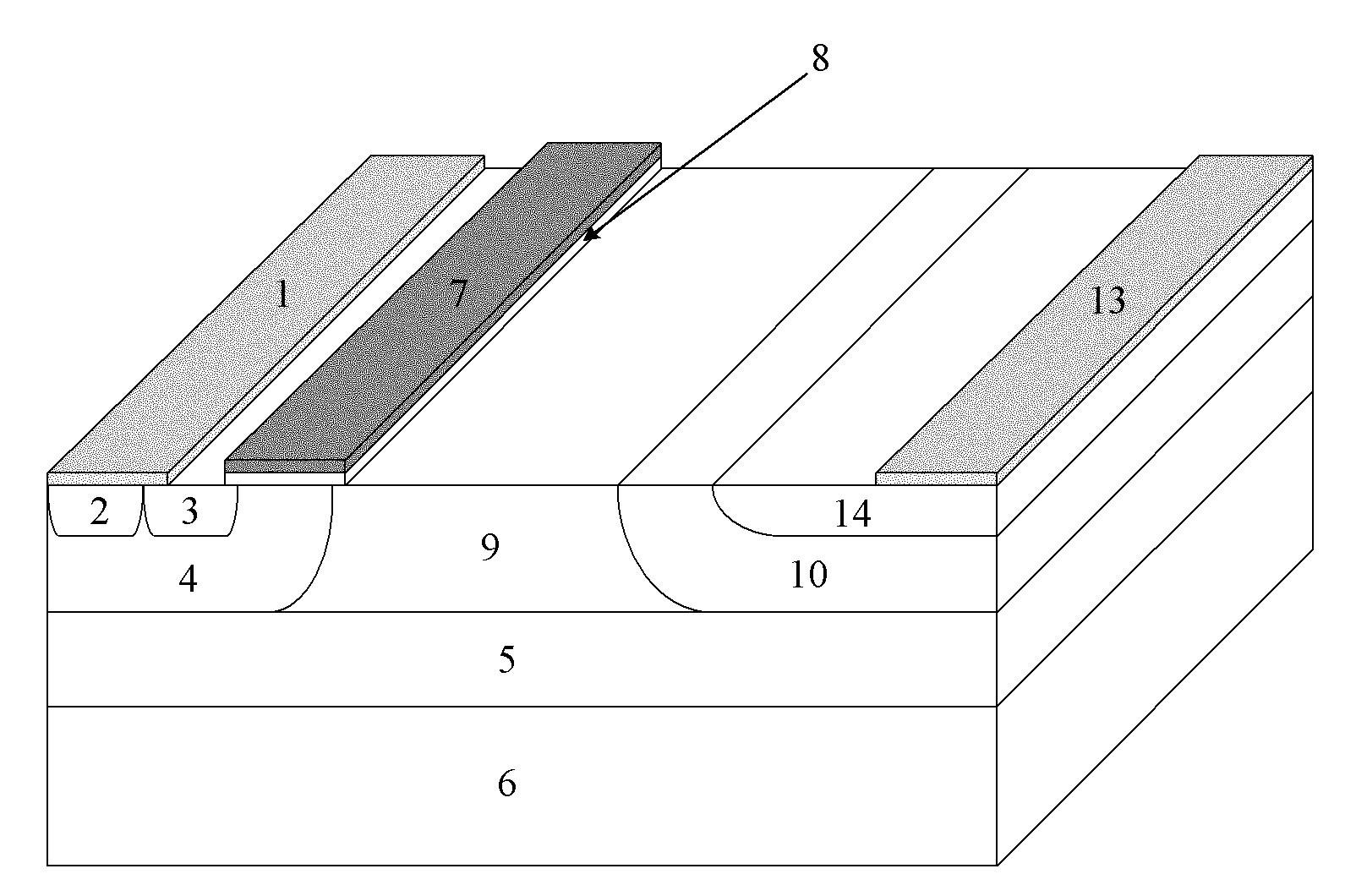

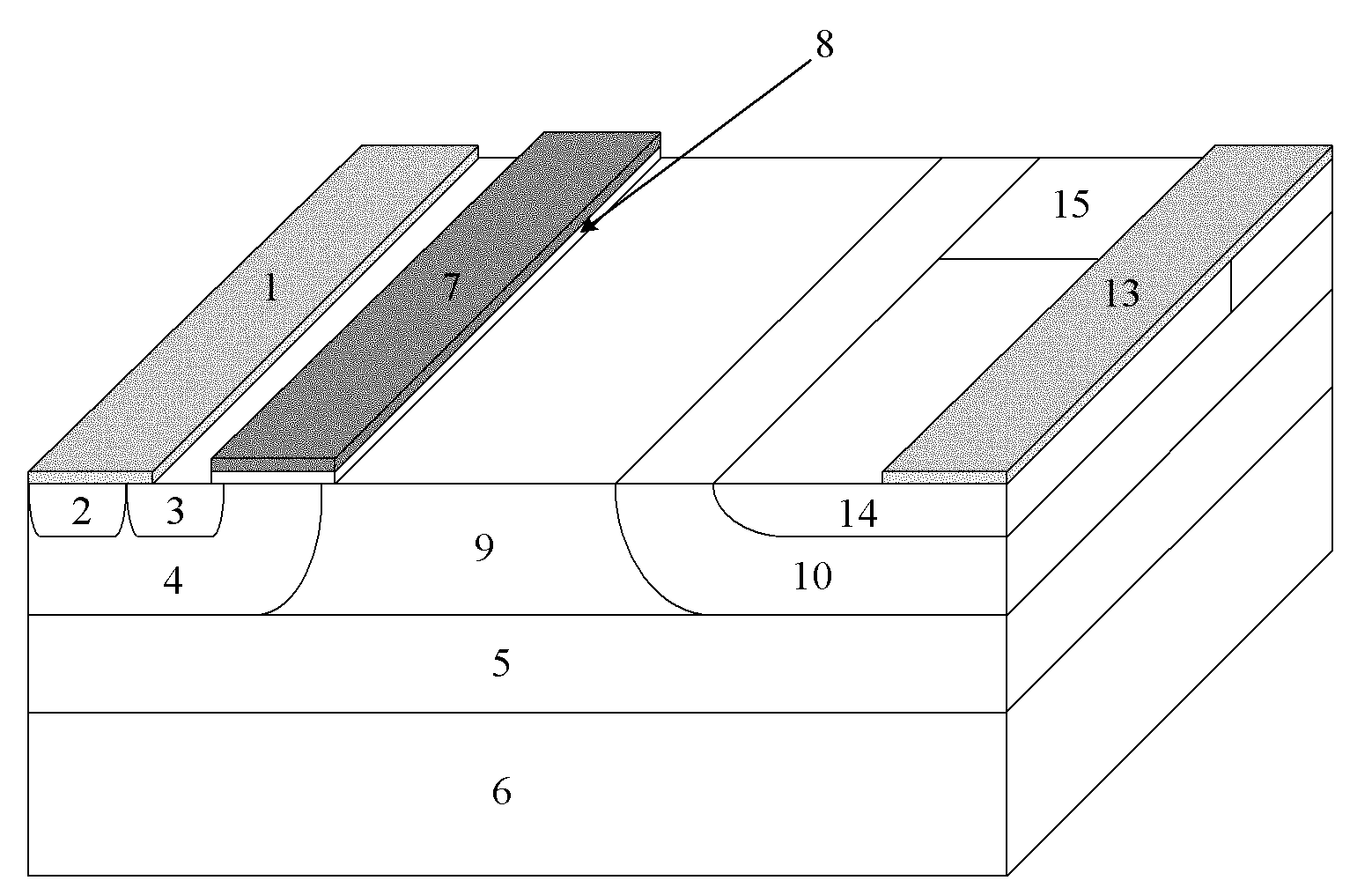

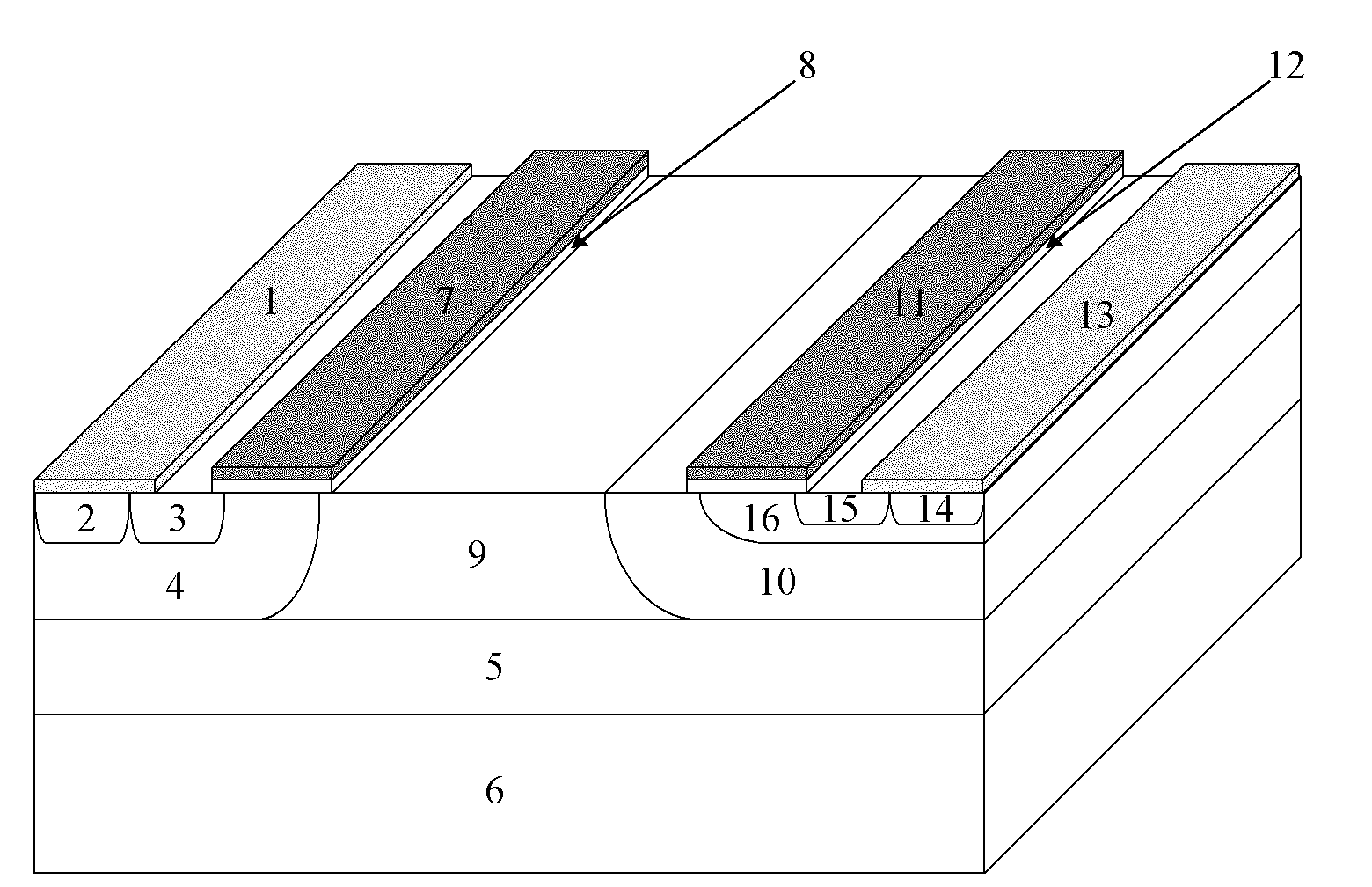

[0019] like Figure 4 As shown, a SOI-LIGBT device with a split anode structure includes an N-type or P-type substrate 6, a buried oxide layer 5 on the surface of the N-type or P-type substrate 6, and a device layer on the surface of the buried oxide layer 5 , the device layer includes an intermediate N - Base area 9, located in N -The cathode region on one side of the base region 9 is located in the N - An anode region on the other side of the base region 9 and a gate region on the cathode region. The cathode region consists of a metallized cathode 1, a P-type body region 4, a P + Cathode 2 and N + The cathode 3 is composed of the P-type body region 4 located on the surface of the buried oxide layer 5 and connected with N - Base 9 contacts, P + Cathode 2 and N + The cathodes 3 are located side by side in the lateral direction in the P-type body region 4 and are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com