Method for producing clean sterilized fresh eggs

A production method and technology of fresh eggs, applied in egg preservation, heating and preservation of eggs, freezing/cooling preservation of eggs, etc., can solve the problems of high production costs, low carbon, and environmental protection (detergents and disinfectants enter groundwater, etc.) , to achieve a high level of hygiene and reduce the number of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

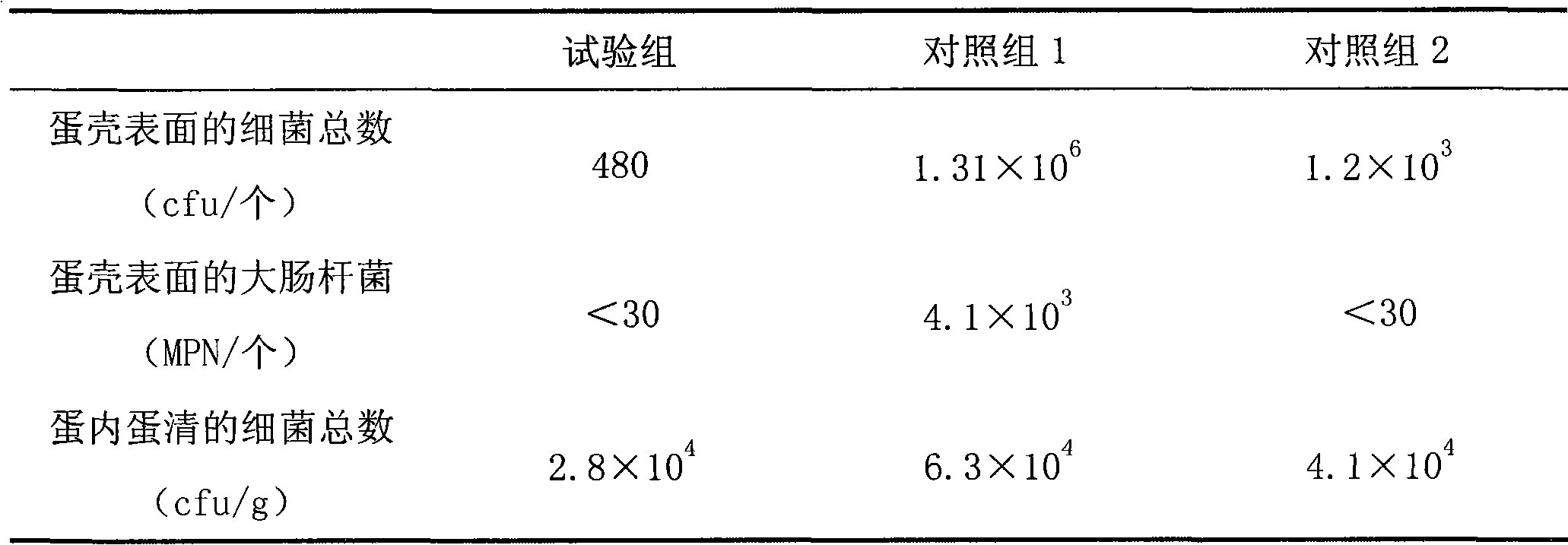

[0021] Embodiment 1 The preparation of cleaning and sterilizing fresh eggs

[0022] In laying hen farms, clean eggs (clean eggs) and "dirty eggs" are sorted into different containers on the artificial egg collector, and then the eggs with clean shell surfaces are placed in homemade clean and sterilized fresh eggs. Egg candidature is completed in the processing equipment (or the equipment used to produce "cleaning eggs"), and eggs that are not suitable for long-term storage, such as cracked eggs, nest eggs, soft preserved eggs, and odd-shaped eggs, are removed, and the conveyor belt enters the sterilization and dust removal process. During the process, fresh eggs roll on the porous conveyor belt, while hot air blows the surface of the eggshell in four directions up, down, left, and right to sterilize and remove floating dust on the surface of the eggshell. The wind speed is 3m / s, the temperature is 140°C, and the hot air The time is 20s. The sterilized and dust-removed fresh e...

Embodiment 2

[0024] The preparation of embodiment 2 cleans and sterilizes fresh eggs

[0025] The processing procedure of "cleaning and sterilizing fresh eggs" is the same as in Example 1, the difference is: ① dirty eggs do not need to be sorted on the egg collector of the laying hen farm, but are completed together in the egg inspection process. ② No flavoring process is used.

Embodiment 3

[0026] Embodiment 3 The preparation of cleaning and sterilizing fresh eggs

[0027] The processing procedure of "cleaning and sterilizing fresh eggs" is the same as in Example 1, except that: ① The hot air velocity is 8m / s, the temperature is 160°C, and the hot air blowing time is 4s. ② The flavoring agent is the ethanol solution of rose essence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com