Polyamide composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane and polyamide technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

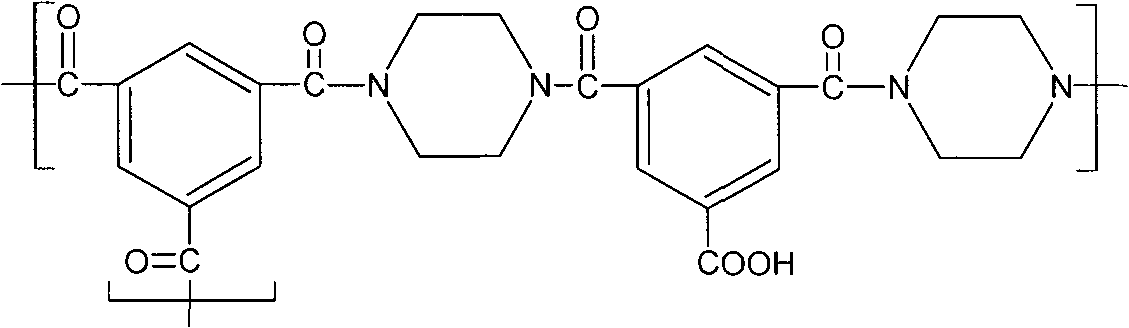

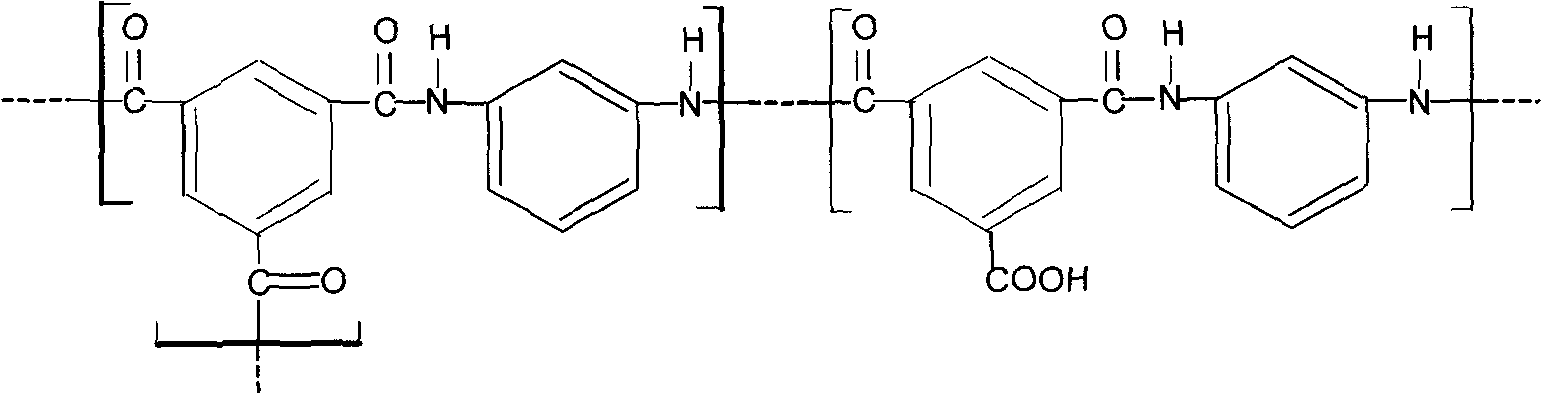

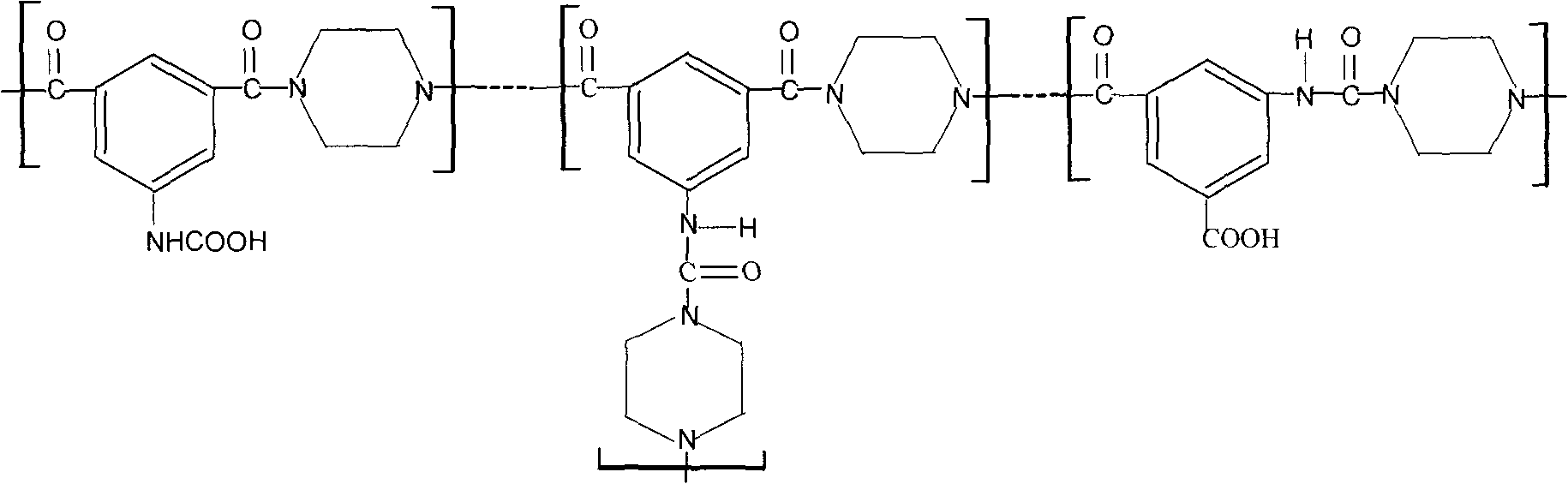

[0037] Preparation of composite nanofiltration membrane: Immerse the wet polysulfone porous support membrane in the polyamine aqueous solution containing acid receiver for 1-10 minutes, roll the surface of the support membrane with a rubber roller, take out the aqueous solution and dry it with nitrogen , carry out single-sided interfacial polymerization reaction with polyacyl chloride solution; wherein the acid receiving agent is triethylamine, or sodium hydroxide, or sodium carbonate, or trisodium phosphate, and the content is 0.5-4wt%; wherein the polyamine is aliphatic Macromolecular polyamine polyvinylamine, the content is 1.0-3.0wt%, the degree of ammonolysis is 0.1-0.9, and the molecular weight is 1000-500,000; the polyacyl chloride is trimesoyl chloride, or 5-isocyanate-isophthaloyl chloride, or 5-oxoformyl chloride-isophthaloyl chloride, the content is 0.05-0.20wt%; the organic solvent used for multi-acyl chloride solution is Isopar G , or trifluorotrichloroethane, or ...

Embodiment 1-7

[0045] Use 13.5wt% Udel PS3500 polysulfone, 0.25wt% water and 0.1wt% nonylphenol polyoxyethyl ester phosphate dissolved in N,N-dimethylformamide, and scrape on the polyester non-woven fabric and then immersed in water to remove the solvent to obtain a polysulfone porous support membrane with a molecular weight cut-off of 80,000-100,000.

[0046] Immerse one side of the wet polysulfone porous support membrane into an aqueous solution containing 3.0wt% triethylamine and 1.0-3.0wt% aliphatic macromolecular polyamine polyethyleneamine (molecular weight=28,000; degree of ammonolysis a=0.53) For 5 minutes, roll the surface of the support film with a rubber roller, drain the aqueous solution and blow dry the surface of the support film with nitrogen, and mix with 0.1wt% polyacyl chloride (respectively trimesoyl chloride (TMC), or 5-isocyanate-iso Phthaloyl chloride (ICIC), or 5-oxoformyl chloride-isophthaloyl chloride (CFIC) n-hexane solution single-sided contact for interfacial poly...

Embodiment 8-14

[0049] As in previous examples, according to the method described above, the acid receiver containing 0.5-4.0wt% (respectively triethylamine, or sodium hydroxide, or sodium carbonate, or trisodium phosphate) and 2.0wt% aliphatic macromolecular Molecular polyamine polyvinylamine (molecular weight=28,000; degree of ammonolysis a=0.53) aqueous solution, trimesoyl chloride (TMC) weight ratio is an organic solvent of 0.1wt% (respectively Isopar G , or trifluorotrichloroethane, or n-hexane, or heptane, or dodecane) solution to prepare composite nanofiltration membrane. These several examples are to investigate the impact of acid receiver and its content, organic solvent on membrane performance.

[0050]

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com