Preparation method and slurry of denitration integral type catalyst

A monolithic catalyst, catalyst technology, applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve problems such as increasing production cost and environmental pollution, achieve suitable for large-scale production, reduce production cost, shorten The effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

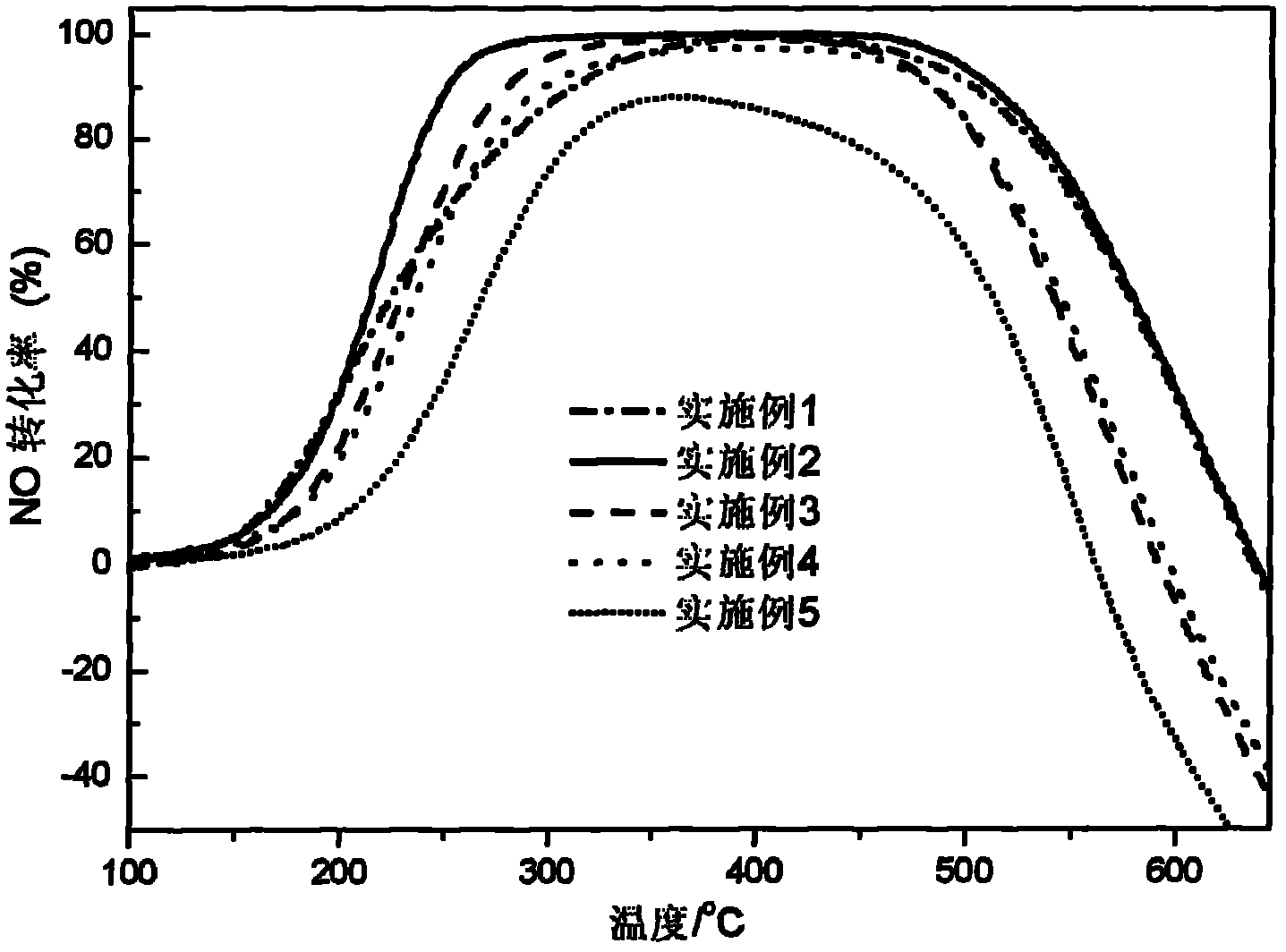

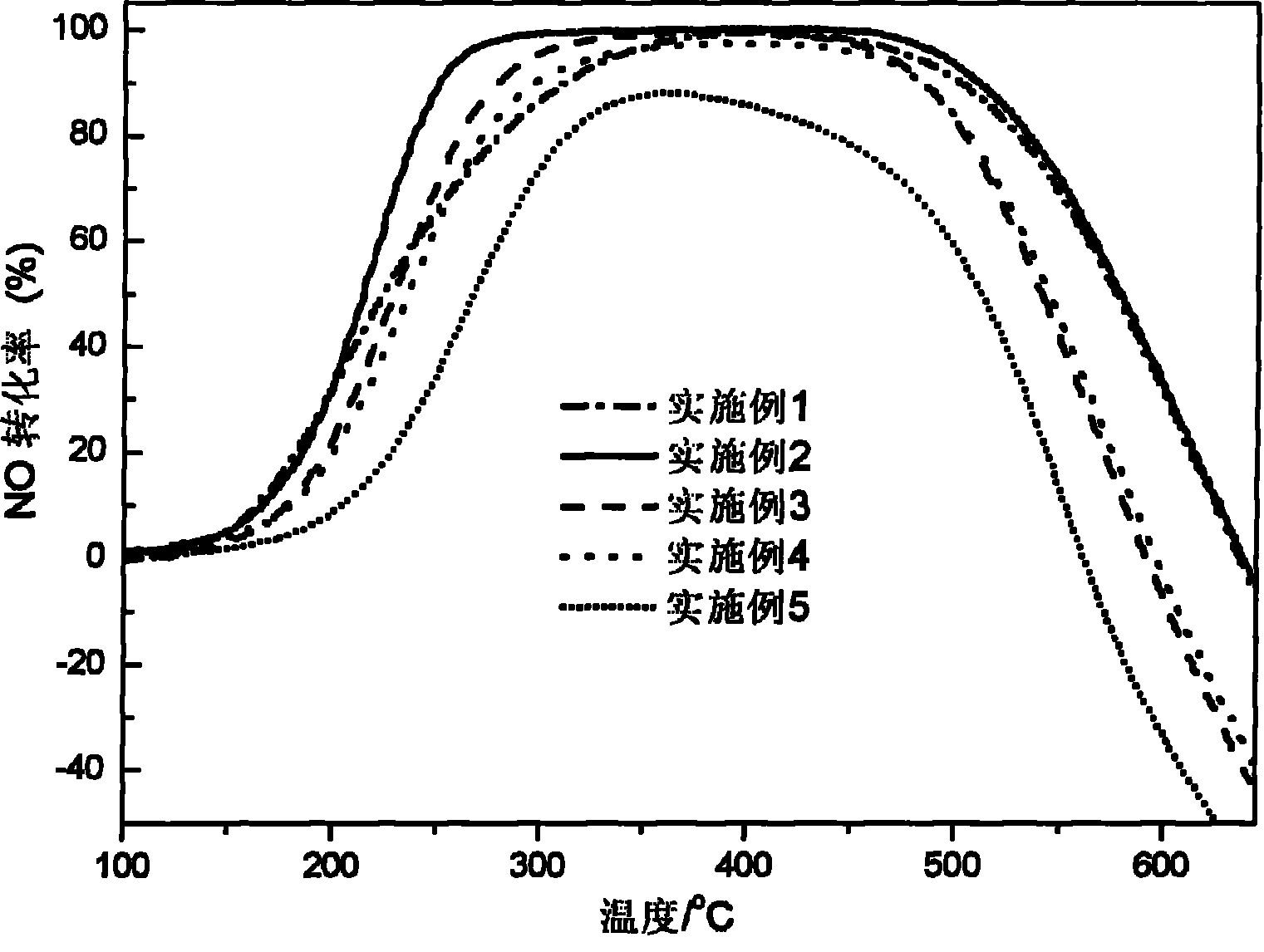

Embodiment 1

[0019] The fired cordierite honeycomb ceramics were weighed. Catalyst V 2 o 5 / WO 3 / TiO 2 After grinding, 8 grams were dispersed in a solution made of 4 grams of water and 8 grams of 20% silica gel, and stirred for 0.5 hour to prepare a slurry with a catalyst content of 40%. Immerse the carrier cordierite honeycomb ceramics in the above slurry, take it out slowly after 5 minutes, dry the residual liquid with an ear washing ball, age at room temperature for 8 hours, dry at 110°C for 4 hours, and then put it in a muffle furnace at 2°C / min The temperature was raised to 550° C. for 2 hours and calcined to obtain a monolithic catalyst for denitration, which was weighed to determine the coating amount.

Embodiment 2

[0021] The fired cordierite honeycomb ceramics were weighed. Catalyst V 2 o 5 / WO 3 / TiO 2 After grinding, 8 grams were dispersed in a solution made of 8 grams of water and 8 grams of 20% silica gel, and stirred for 1.5 hours to prepare a slurry with a catalyst content of 33.3%. Immerse the carrier cordierite honeycomb ceramics in the above slurry, take it out slowly after 5 minutes, dry the residual liquid with an ear washing ball, age at room temperature for 8 hours, dry at 110°C for 4 hours, and then put it in a muffle furnace at 2°C / min The temperature was raised to 550° C. for 2 hours and calcined to obtain a monolithic catalyst for denitration, which was weighed to determine the coating amount.

Embodiment 3

[0023] The fired cordierite honeycomb ceramics were weighed. Catalyst V 2 o 5 / WO 3 / TiO 2 After grinding, 6.4 g was dispersed in a solution made of 8 g of water and 8 g of 20% silica gel, and stirred for 1.5 hours to prepare a slurry with a catalyst content of 28.6%. Immerse the carrier cordierite honeycomb ceramics in the above slurry, take it out slowly after 5 minutes, dry the residual liquid with an ear washing ball, age at room temperature for 8 hours, dry at 110°C for 4 hours, and then put it in a muffle furnace at 2°C / min The temperature was raised to 550° C. for 2 hours and calcined to obtain a monolithic catalyst for denitration, which was weighed to determine the coating amount.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com