Ceramic composite grinding roller of medium speed coal grinding mill

A ceramic composite, coal mill technology, applied in the field of coal mill grinding rollers, can solve the problems of inconvenience of normal production, short service cycle, reduced production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

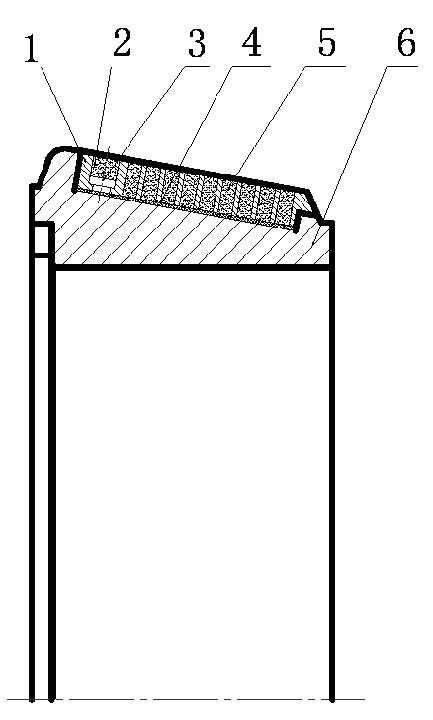

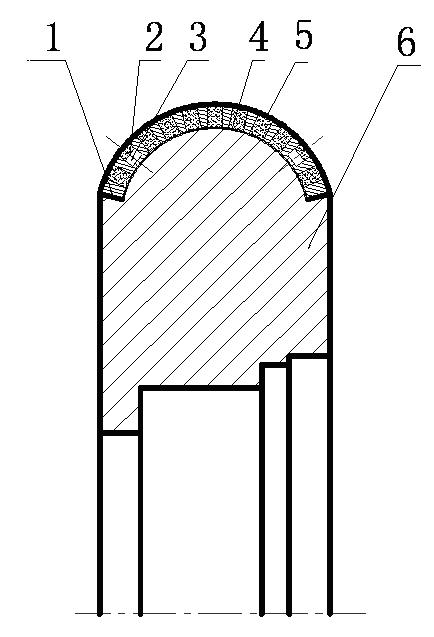

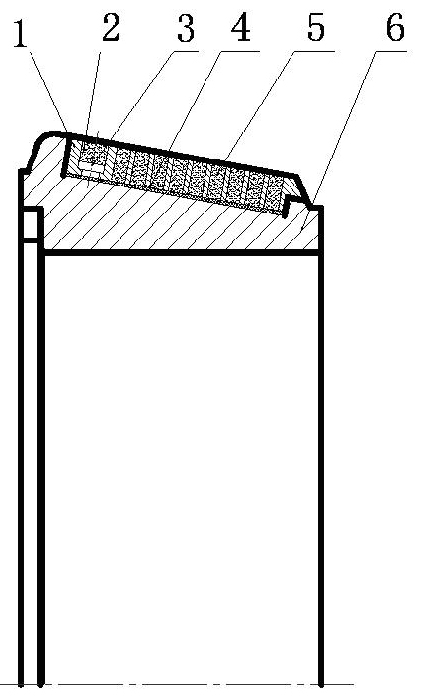

[0011] A ceramic composite grinding roller for a medium-speed coal mill, including an arc-shaped liner 1 cast from a high-chromium alloy. The arc-shaped liner is provided with a through hole, and the shape of the through hole can be cylindrical, prismatic, or conical. etc., the oxide, carbide or nitride ceramic rod 5 is embedded with a binder in the through hole, the arc-shaped liner and the ceramic rod form a metal-ceramic composite plate, and the metal-ceramic composite plate and the roller core 6 pass through the binder 4 Bonding, and directly fasten the roller core with the bolt 3 coated with thread adhesive through the through hole on the arc liner, and the ceramic cover 2 is embedded above the bolt.

[0012] There is an adhesive layer between the metal-ceramic composite arc liner and the roller core, and is fixed on the roller core by bolts, and the roller core is made of carbon cast steel.

[0013] At manufacture time:

[0014] (1) Install the ceramic rod inside the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com