Chelate type flashing erosion-resistant water-based metal anticorrosion coating and preparation method thereof

A metal anti-corrosion and chelating technology, applied in anti-corrosion coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems affecting the anti-corrosion effect and service life of coatings, restrict the popularization and application of water-based metal anti-corrosion coatings, etc. Corrosion resistance, high film density, and corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

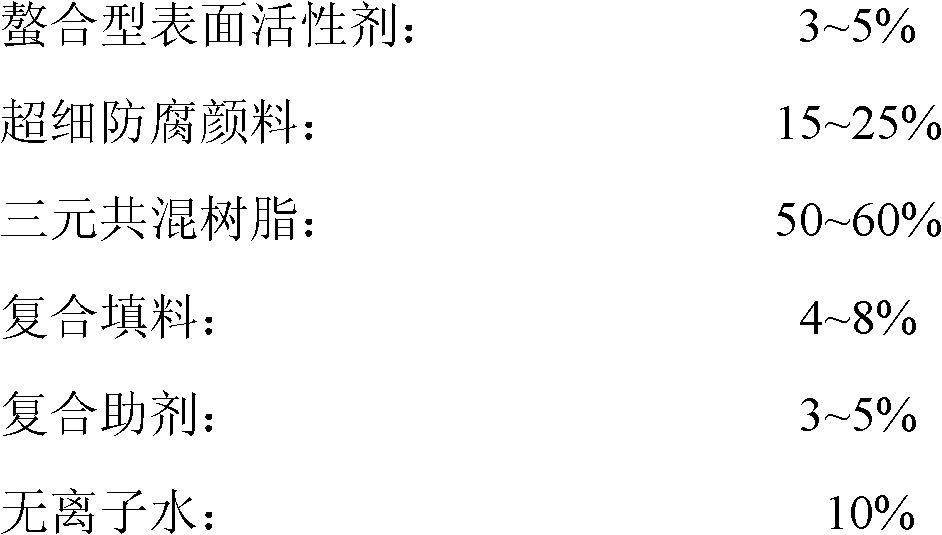

[0028] Under stirring, add 3 kg of chelating surfactant N-dodecylethylenediamine triacetate sodium, 5 kg of compound additives and 10 kg of deionized water into the mixing tank, slowly add 7 kg of compound filler within 10 minutes, and continue stirring 20 minutes; within 40 minutes, evenly add 25kg of superfine anti-corrosion pigment zinc calcium phosphate, and continue to stir for 20 minutes; after the obtained color paste is dispersed and homogenized by a high-shear emulsifier for 30 minutes, it is sent to a horizontal sand mill for grinding for 60 minutes to obtain Pigment paste with particle size ≤10μm.

[0029] Add 50 kg of ternary blending resin into the mixing tank, under high-speed stirring at 1400 rpm, slowly add the above-mentioned pigment and filler color paste within 30 minutes, and continue stirring for 60 minutes to obtain a chelating type anti-flash corrosion water-based metal anti-corrosion coating product.

Embodiment 2

[0031] Under stirring, add 4 kg of chelating surfactant N-dodecanoyl ethylenediamine triacetate sodium, 4 kg of compound additives and 10 kg of deionized water into the mixing tank, slowly add 6 kg of compound filler within 10 minutes, and continue stirring 20min; within 40 minutes, evenly add 21kg of superfine anti-corrosion pigment aluminum zinc phosphate, and continue to stir for 20 minutes; after the obtained color paste is dispersed and homogenized by a high-shear emulsifier for 30 minutes, it is sent to a horizontal sand mill for grinding for 60 minutes to obtain Pigment paste with particle size ≤10μm.

[0032] Add 55 kg of ternary blend resin into the mixing tank, and slowly add the above-mentioned pigment and filler color paste within 30 minutes under high-speed stirring at 1400 rpm, and continue stirring for 60 minutes to obtain a chelating type anti-flash corrosion water-based metal anti-corrosion coating product.

Embodiment 3

[0034] Under stirring, add 5 kg of chelating surfactant lauryl monoester citrate, 3 kg of compound additives and 10 kg of deionized water into the mixing tank, slowly add 4 kg of composite fillers within 10 min, and continue stirring for 20 min; Within minutes, add 18kg of superfine anti-corrosion pigment composite iron-titanium powder evenly, and continue to stir for 20 minutes; the resulting color paste is dispersed and homogenized by a high-shear emulsifier for 30 minutes, and then sent to a horizontal sand mill for grinding for 60 minutes to obtain a particle size of ≤10 μm pigment paste.

[0035] Add 60 kg of ternary blend resin into the mixing tank, and slowly add the above-mentioned pigment and filler color paste within 30 minutes under high-speed stirring at 1400 rpm, and continue stirring for 60 minutes to obtain a chelating type anti-flash corrosion water-based metal anti-corrosion coating product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com