Kinetic resolution method of secondary alcohol

A technology of kinetic resolution and secondary alcohol, which is applied in fermentation and other directions, can solve the problems of slow reaction rate, low optical purity of products, and reduce the application scope of enzymatic kinetic resolution process, so as to achieve maximum application value and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

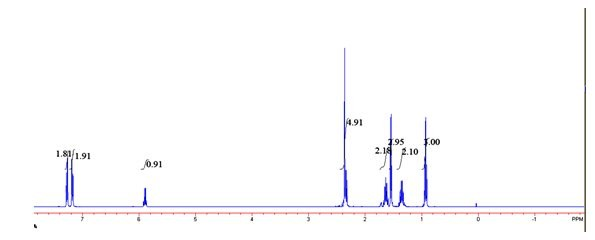

Embodiment 1

[0022] 1) Add p-chlorophenol, propionic acid, dicyclohexylcarbodiimide and 4-dimethylaminopyridine with a molar ratio of 1:1:1:0.03, stir and react for 7 hours, filter, dry the filtrate, concentrate, pass column, obtain p-chlorophenyl propionate as an acyl donor for subsequent use;

[0023] 2) Add phenylethyl alcohol and p-chlorophenyl propionate at a molar ratio of 1:0.5 to 2 mL of toluene, react with 5 mg / mL Novozyme 435 for 3 hours at a reaction temperature of 30°C, and obtain a conversion rate of 50%, e.e. >99% esters.

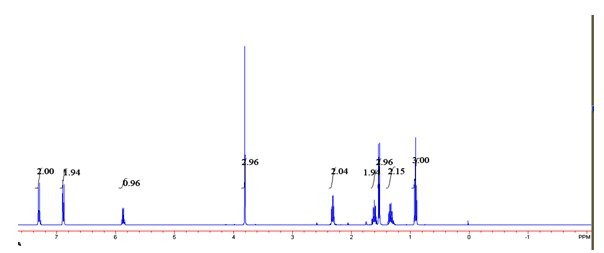

Embodiment 2

[0025] 1) Add p-chlorophenol, n-butyric acid, dicyclohexylcarbodiimide and 4-dimethylaminopyridine in a molar ratio of 1:2:2:0.05, stir for 3 hours, filter, dry the filtrate, concentrate, Go through the column to obtain p-chlorophenyl n-butyrate as an acyl donor for subsequent use;

[0026] 2) Add phenylethyl alcohol and p-chlorophenyl butyrate at a molar ratio of 1:3 to 6 mL of toluene, react with 20 mg / mL Novozyme 435 for 0.5 hours at a reaction temperature of 60°C, and obtain a conversion rate of 50%, e.e. >99% esters.

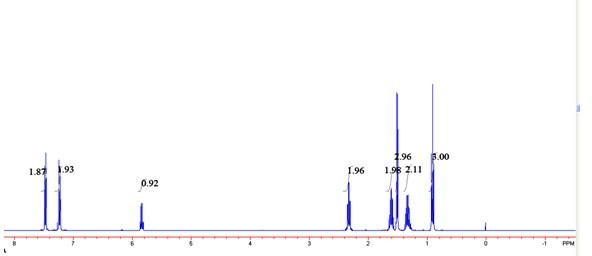

Embodiment 3

[0028] 1) Add p-chlorophenol, n-valeric acid, dicyclohexylcarbodiimide and 4-dimethylaminopyridine with a molar ratio of 1:1.5:1.5:0.05, stir and react for 6 hours, filter, dry the filtrate, concentrate, Go through the column to obtain p-chlorophenyl valerate as an acyl donor for subsequent use;

[0029] 2) Add phenylethyl alcohol and p-chlorophenyl valerate in a molar ratio of 1:2 to 2 mL of toluene, react with 10 mg / mL Novozyme 435 for 0.5 hours at a reaction temperature of 40°C, and obtain a conversion rate of 50%, e.e. >99% esters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com