Subzero treatment technology for hard alloy saw blade tool bit

A cemented carbide and cryogenic treatment technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as unlikely and immature processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] The cemented carbide cutter bit involved in the following embodiments is the KCR06 brand.

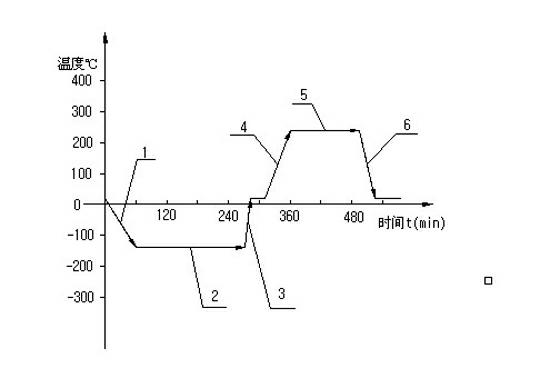

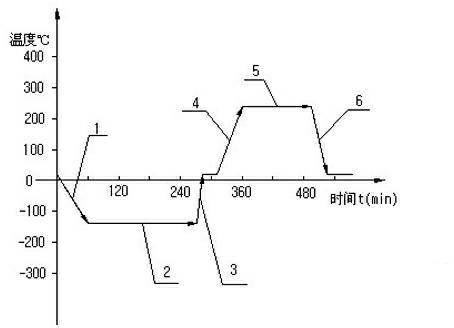

[0017] see figure 1 , the cryogenic treatment process of the cemented carbide cutter head of the KCR06 brand is: from room temperature 20°C, with a cooling rate of 2°C per minute, the temperature of the cutter head is dropped to -120°C ~ -160°C, in a cryogenic state Keep warm for 120 minutes to 300 minutes, then return to room temperature in the air. After reaching room temperature, perform low temperature tempering. The hardness is 93.5-95.1HRA, and the bending strength is 2300-2500MPa.

[0018] The following table is the specific parameters and hardness, bending strength performance table of each implementation example:

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com