System for pre-drying coal with high water content by utilizing residual heat of boiler gas

A boiler flue gas and pre-drying technology, which is applied in drying gas layout, drying, dryer and other directions, can solve the problems of reducing the heat utilization efficiency of flue gas, large exhaust gas volume of boiler, and large ventilation volume of coal mill. , to achieve the effect of reducing sewage treatment costs, increasing cooling water consumption, and reducing water consumption and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

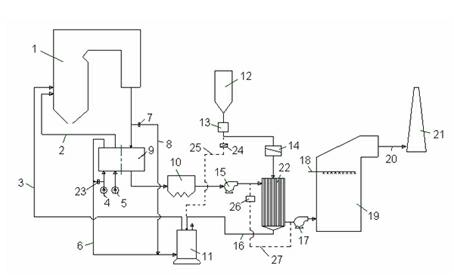

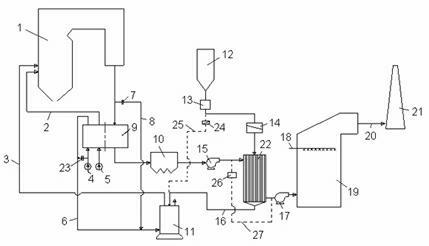

[0036] The following combination Figure 1 ~ Figure 2 , a preferred embodiment of the present invention is described in detail.

[0037] Such as figure 1 As shown, it is a schematic structural diagram of a system for pre-drying high-moisture coal by utilizing boiler flue gas waste heat provided by the present invention. It includes: a boiler 1, a flue gas pretreatment system, a raw coal pre-drying system and a desulfurization system connected sequentially through a flue gas pipeline; it also includes a raw coal pretreatment system and a coal mill 11; The pre-drying system is connected; the coal mill 11 is respectively connected with the raw coal pre-drying system and the boiler 1 through the coal delivery pipeline, and the coal mill 11 is also connected with the flue gas pretreatment system through the flue gas pipeline.

[0038] Wherein, the flue gas pretreatment system includes an air preheater 9 and an electric precipitator 10 connected in sequence. The air preheater 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com