Electro-hydraulic servo control system

A control system, electro-hydraulic servo technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of increasing operation and maintenance costs, increasing the possibility of failure, increasing investment, etc., to save investment and related costs, Reduced maintenance costs and excellent reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described below in conjunction with preferred embodiments.

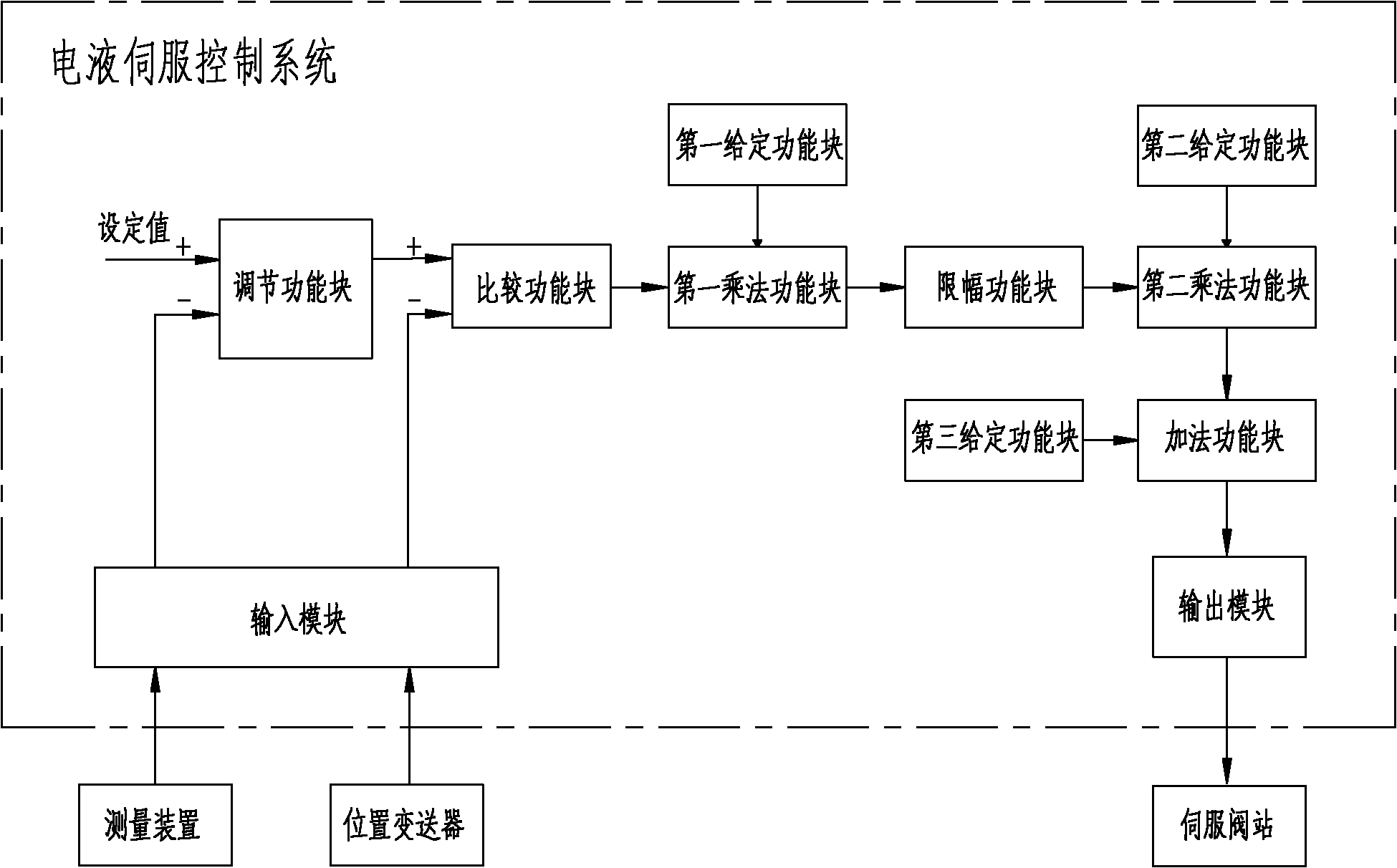

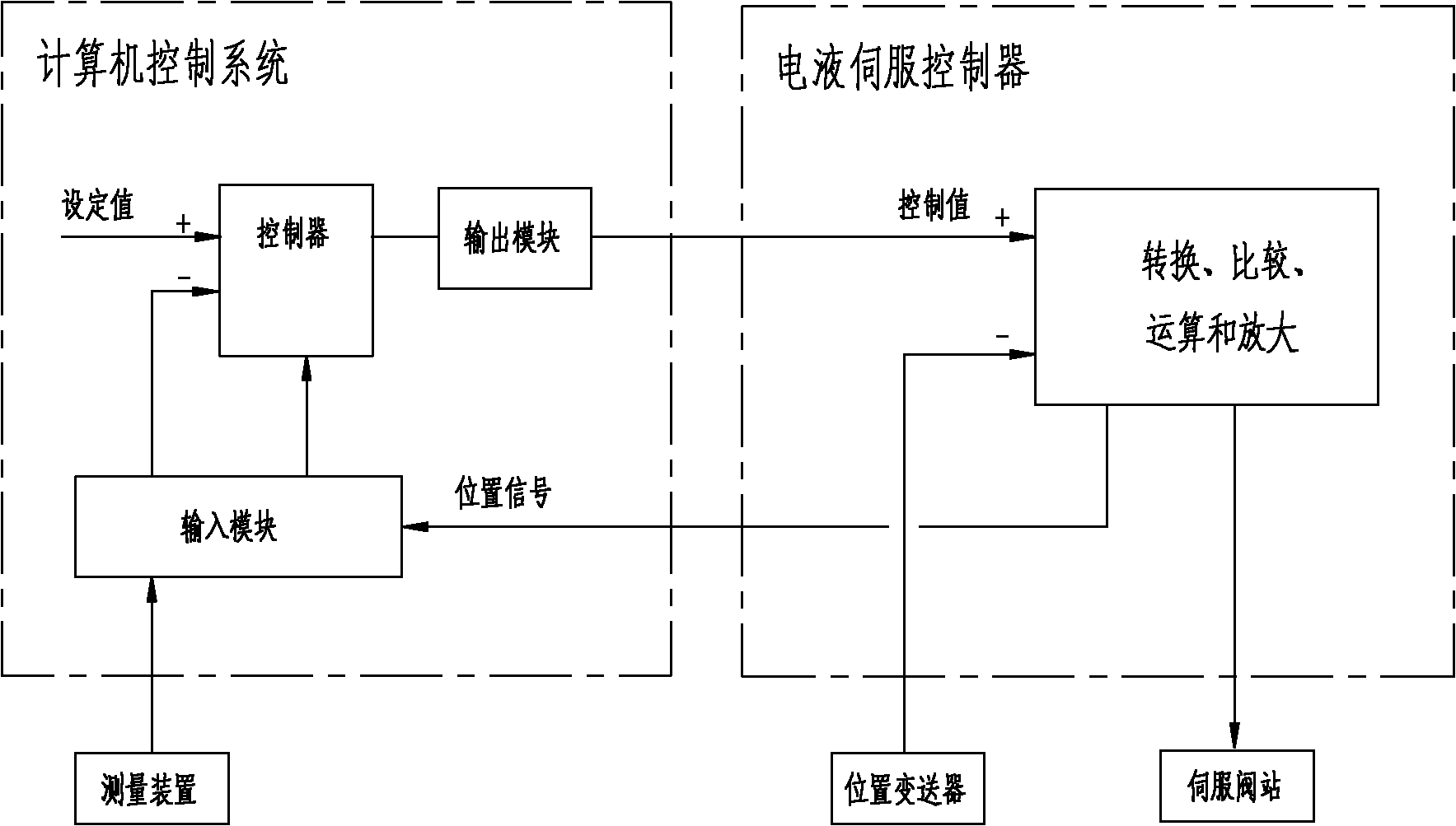

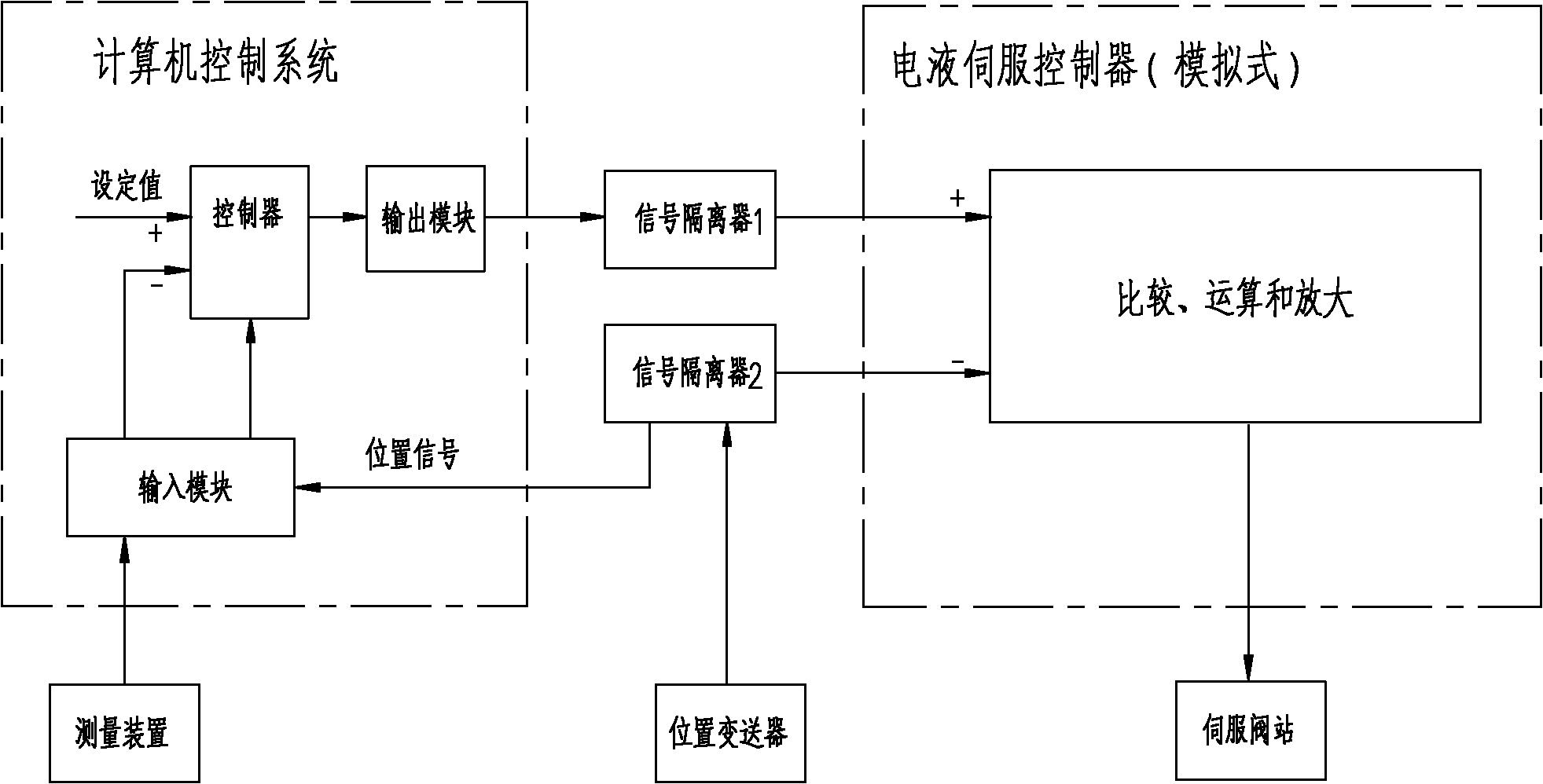

[0031] An electro-hydraulic servo control system includes an input module, an output module, a first given function block, a second given function block, a third given function block, an adjustment function block, a comparison function block, a first multiplication function block, a second The quadratic function block, limiter function block and addition function block, the above-mentioned modules are connected to each other through cables and computer software to realize the electro-hydraulic servo control function, which can meet the control requirements of various signal-controlled servo valves (including proportional valves) in the hydraulic system. .

[0032] The input module accepts the output of the measuring device and the position transmitter, and is used to realize various on-site signal (such as 4-20mA DC) acquisition, analog-to-digital conversion and isolation.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com