Manufacturing method of membrane electrode of novel ultrathin proton exchange membrane fuel cell

A proton exchange membrane, fuel cell membrane technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult to accurately control the thickness of the catalytic layer, unsuitable for making an area of MEA, affecting the size of the electrode, etc., to enhance the reverse diffusion capability. , improve performance, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

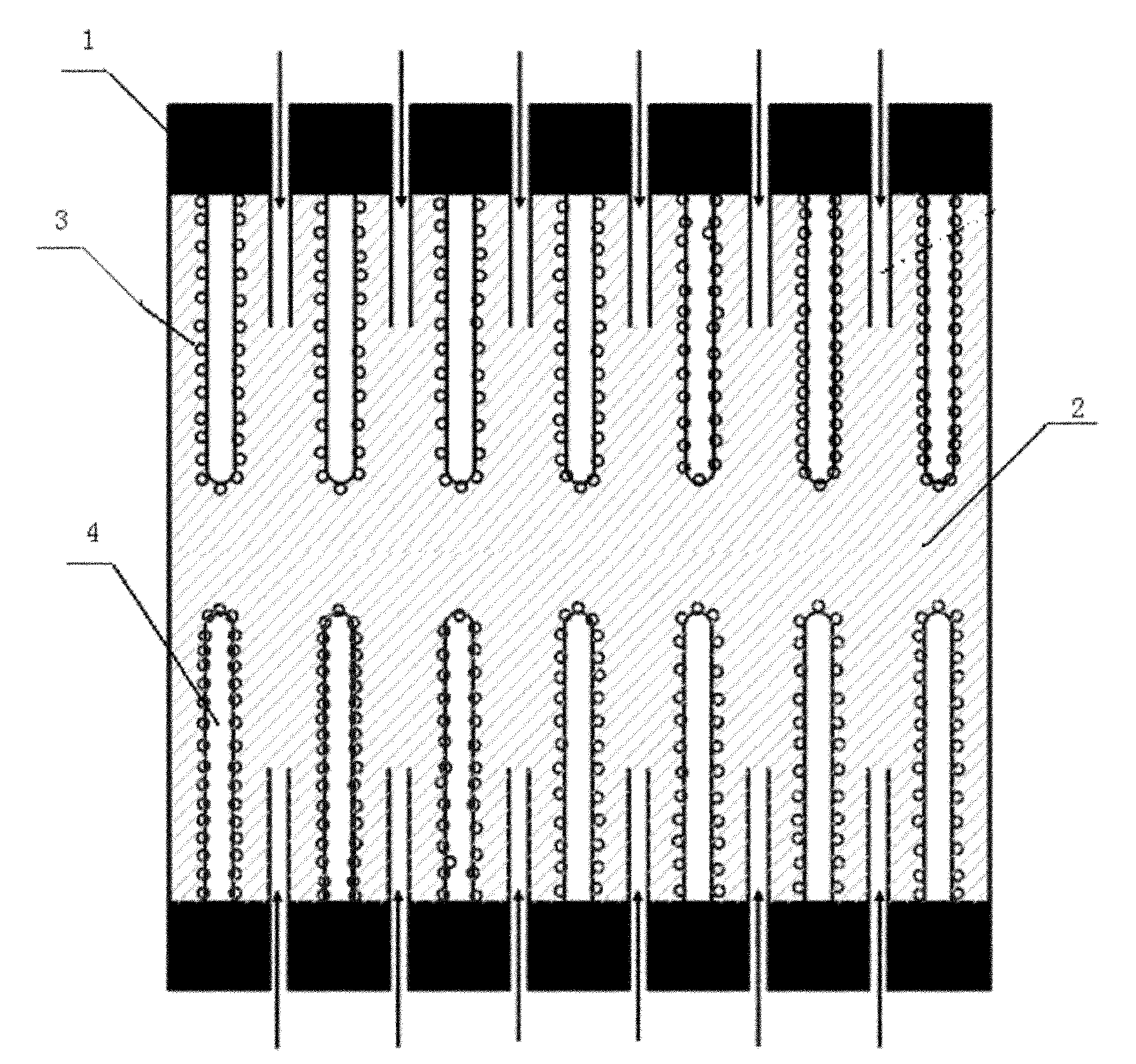

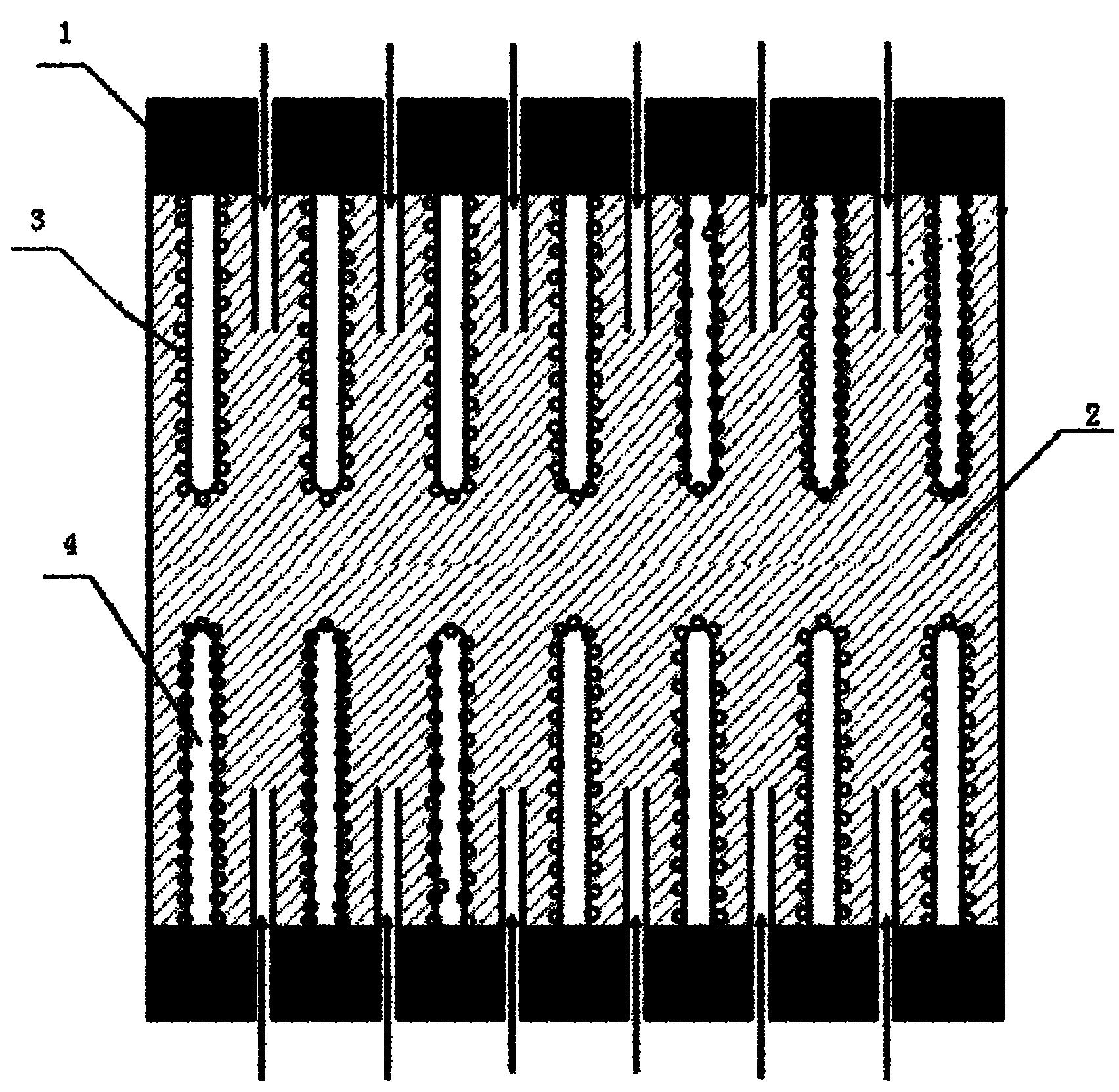

[0034] see figure 1 , a novel ultra-thin proton exchange membrane fuel cell membrane electrode comprising a support layer of carbon paper 1, plasma polymerized proton exchange membrane 2, aligned nanotubes 4, Pt nanoparticles or PtRu nanoparticles 3 sputtered on the aligned nanotubes 4 .

[0035] Concrete preparation comprises the following steps:

[0036] 1. Hydrophobic carbon paper preparation: treat 5cm×5cm carbon paper with PTFE (5wt% PTFE) as a support layer;

[0037] 2. Preparation of Ni catalyst layer for directional carbon nanotube growth:

[0038] (1) Plasma Cleaning Use hydrophobic carbon paper as the deposition substrate of the metal Ni catalyst layer grown by oriented carbon nanotubes, put it into the vacuum chamber substrate stage, and pump the background vacuum to 10 -3 Below Pa, pass argon gas to the pressure of about 1Pa, control the negative bias voltage of the substrate at about 100V, and perform radio frequency plasma discharge cleaning for 5 minutes unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com