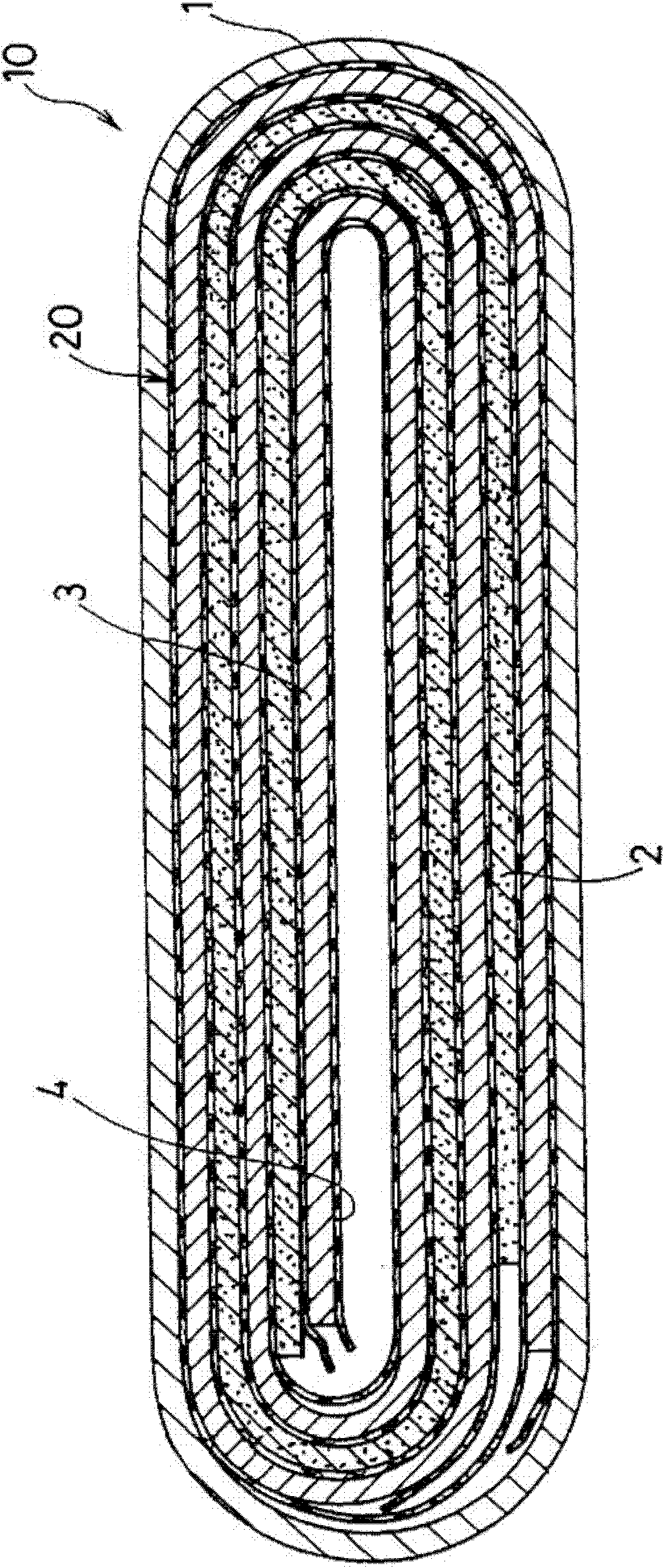

Separator for lithium secondary batteries, and lithium secondary battery using same

A lithium secondary battery and diaphragm technology, applied in the field of lithium secondary batteries and lithium secondary battery diaphragms, can solve the problems of small slippage of the diaphragm, damage to the diaphragm, and inability to pull out the winding core, etc., to achieve improved sliding and smoothness Pulling operation, the effect of improving pull-out performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

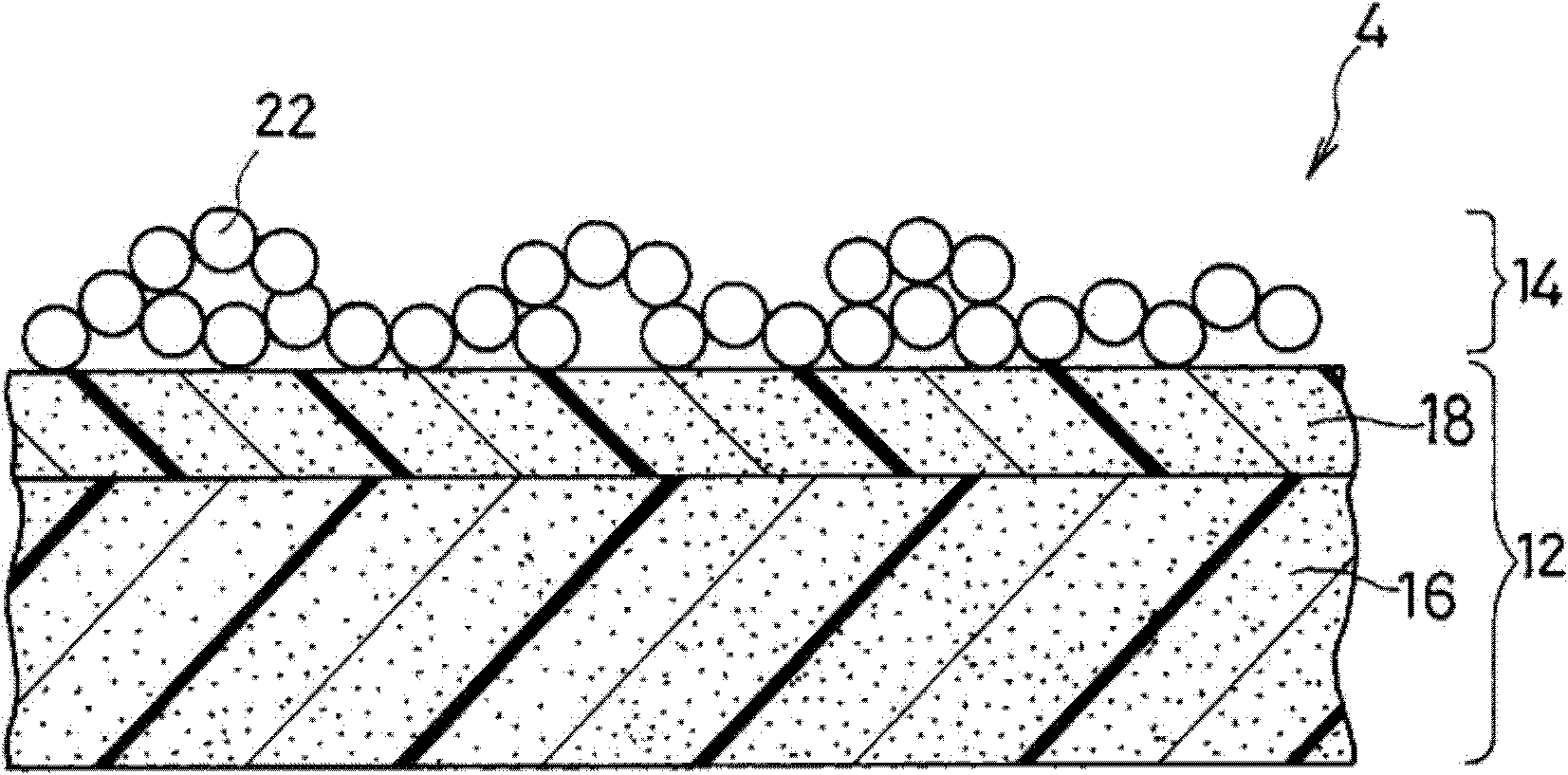

[0117] In the order shown below, make image 3 Diaphragm 4 shown.

[0118] (1) As the polyolefin layer 16 , a porous polyethylene film with a thickness of 20 μm was used. This film is produced by melt-extruding polyethylene and biaxially stretching the resulting molded product. The pore diameter is 0.1-1 μm, so as not to allow the active material, binder and conductive agent detached from the positive electrode 2 and the negative electrode 3 to pass through.

[0119] (2) As the heat-resistant porous layer 18 , a porous film containing polyamide was formed on one surface of the polyolefin layer 16 with a thickness of 3.5 μm. The porous membrane containing polyamide is formed by dissolving polyamide in N-methyl-2-pyrrolidone (NMP), applying the obtained solution on one side of the polyolefin layer 16 and drying it. In the solution, 200 parts by weight of an inorganic oxide (alumina having an average particle diameter of 0.013 μm) was dispersed per 100 parts by weight of polya...

Embodiment 2

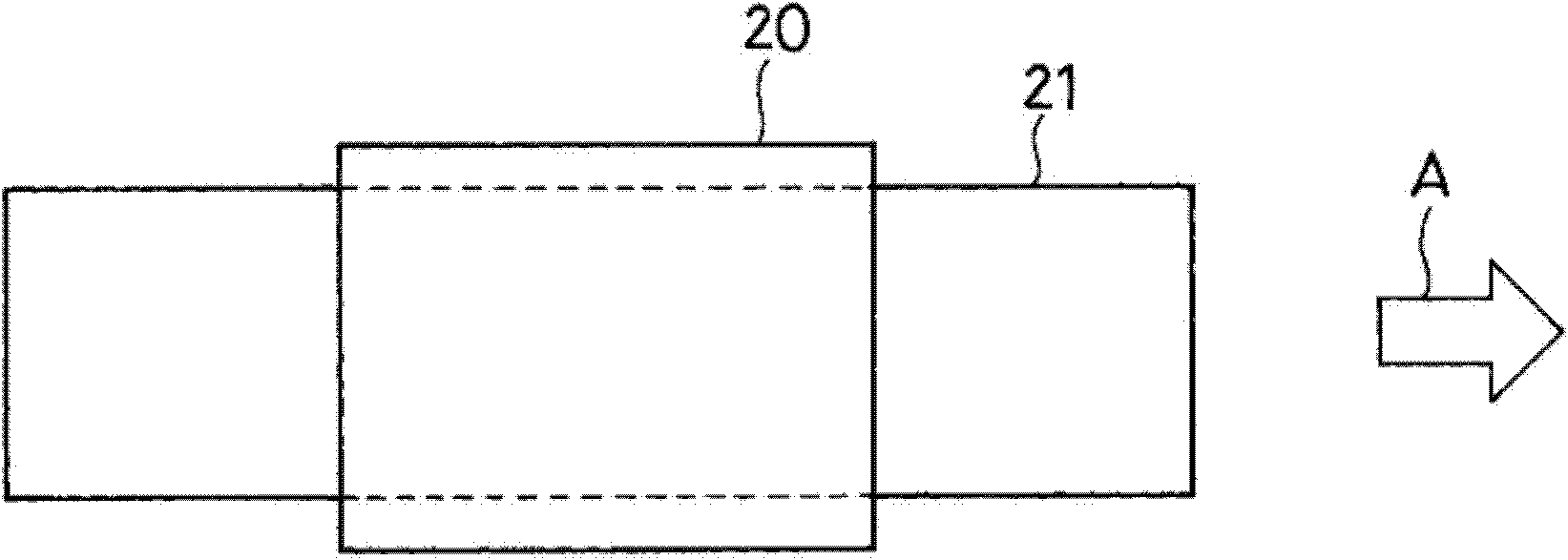

[0132] As the particulate matter 22, spherical particles of perfluoroethylene propylene copolymer (FEP) having an average particle diameter of 0.2 μm were used, and the dry weight of the particulate matter 22 in the lubricating layer 14 was changed to 0.8 g / m 2 , except that, in the same manner as in Example 1, 1,000 lithium secondary batteries were produced. The surface roughness Sa of the lubricating layer 14 formed was 1.4 μm.

[0133] In the same manner as in Example 1, when the electrode group 20 was constructed, the appearance inspection of the produced electrode group 20 was carried out while observing the state of pulling out the winding core 21 . In addition, battery characteristics were evaluated in the same procedure as in Example 1.

Embodiment 3

[0135] As the particulate matter 22, SiO with an average particle diameter of 0.1 μm is used 2 spherical particles, while changing the dry weight of the particulate matter 22 in the lubricating layer 14 to 0.3g / m 2 , except that, a lithium secondary battery was produced in the same manner as in Example 1. The surface roughness Sa of the lubricating layer 14 formed was 0.2 μm.

[0136] In the same manner as in Example 1, when the electrode group 20 was constructed, the appearance inspection of the produced electrode group 20 was carried out while observing the state of pulling out the winding core 21 . In addition, battery characteristics were evaluated in the same procedure as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com